Air craft

A spaceship and hull technology, applied in the field of spaceships, can solve the problems of increasing ship weight and manufacturing costs, affecting the vision of drivers and passengers, increasing navigation fuel consumption, etc., and achieving safe and reliable high-speed navigation, light weight, and increased carrying capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

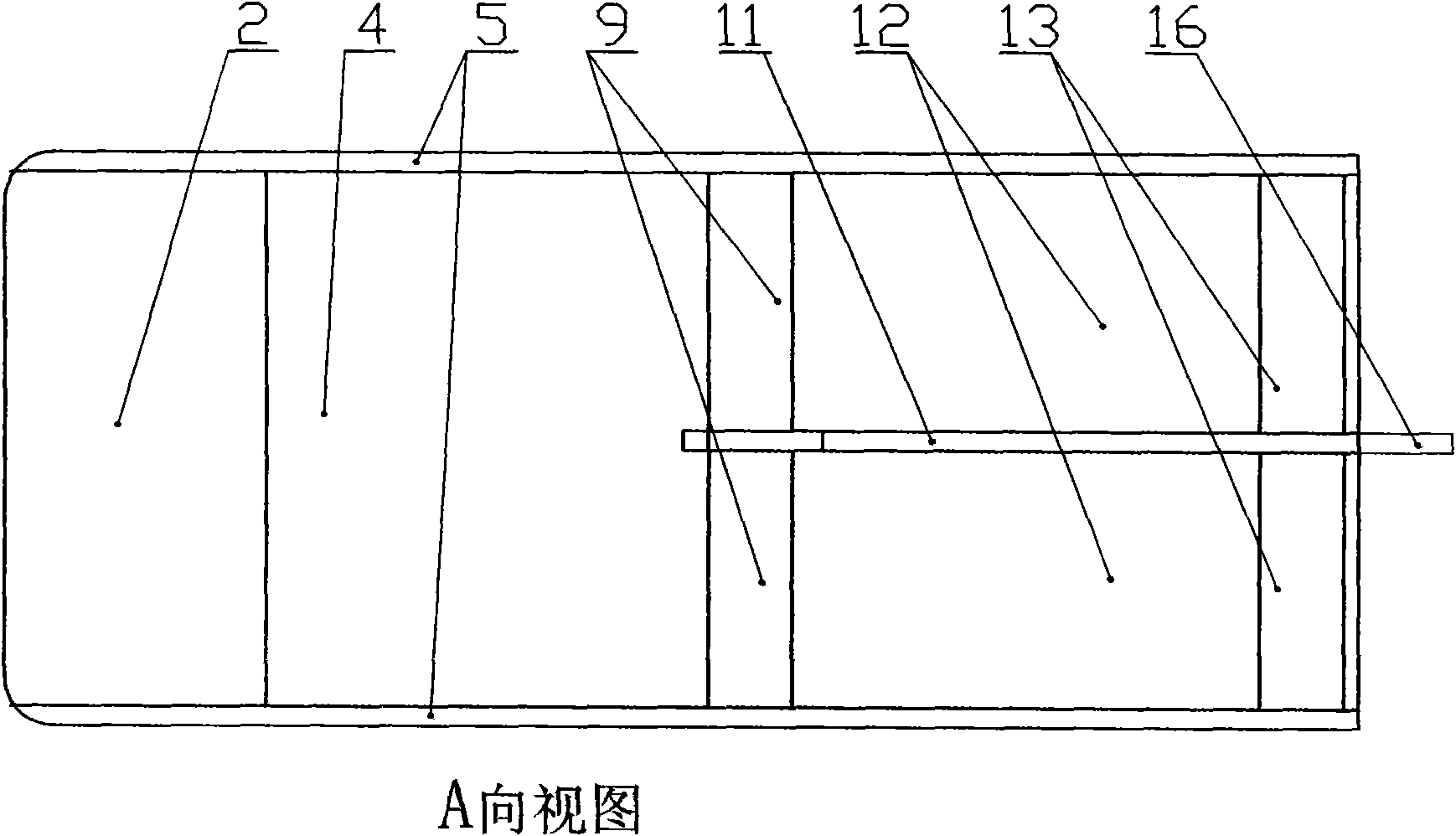

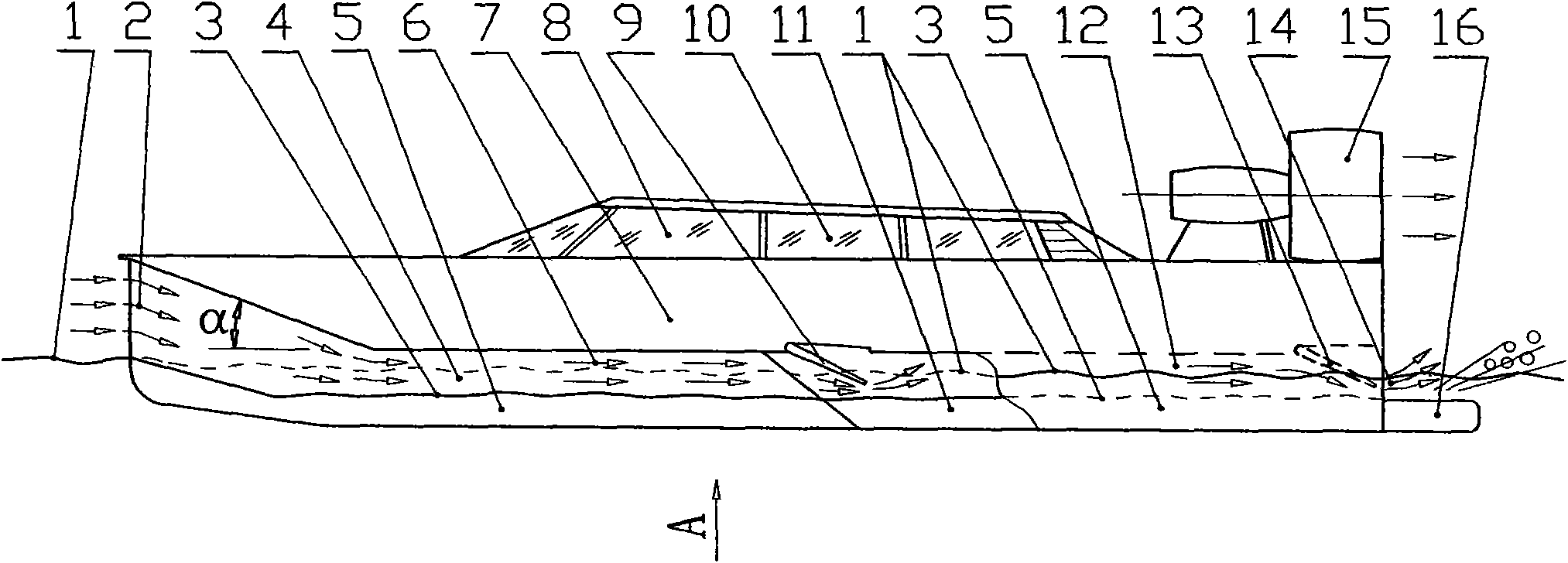

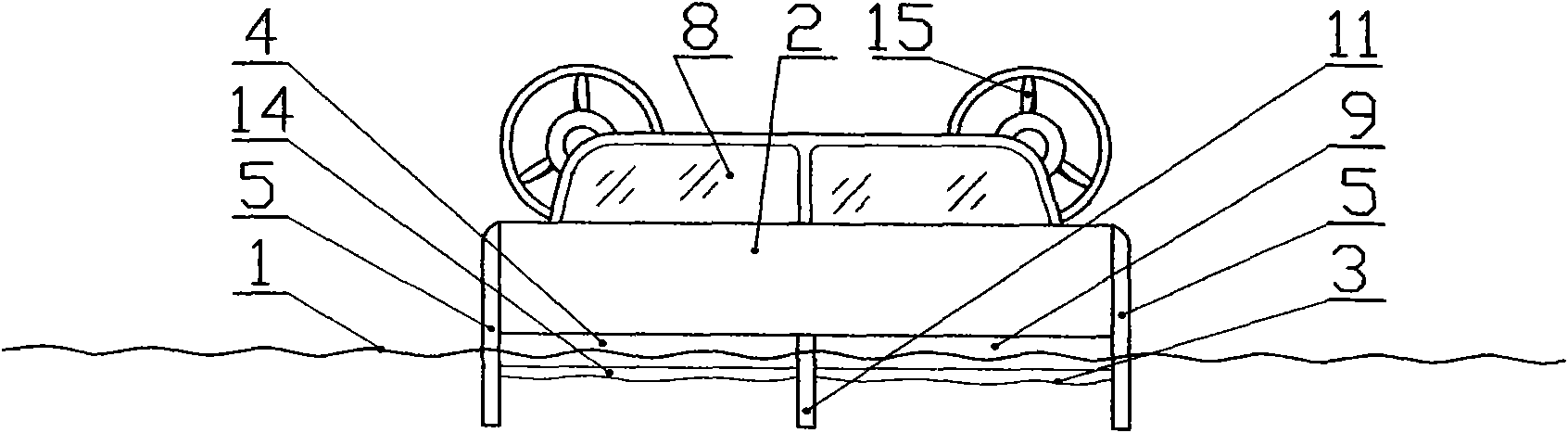

[0023] Example one: figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , As shown, in the flat bottom hull 7, parallel two sides extending from the bottom of the ship, inserted into the water between the rigid two side walls 5 midship to the stern, there are one or more out of the bottom of the ship, inserted into the water parallel to the side wall 5 rigid The air baffle 11 forms an open front air passage 4 and two or more rear air passages 12 at the bottom of the ship. The front end and the stern end of each rear air passage are provided with two adjustable angles. One or more front valves 9 and rear valves 13 are provided at the bottom of the bow of the front air passage 4 with a bow-shaped air inlet 2 with a larger section than the front air passage 4 and a bow flared at a high angle of attack α.

Embodiment 2

[0024] Embodiment two: Figure 7 , Figure 8 , Picture 9 As shown, in the flat-bottomed hull 7, the parallel sides extend out from the bottom of the ship and are inserted between the rigid two side walls 5 in the water from the bow to the stern. There are one or more rigid partitions extending from the bottom of the ship and inserted into the water parallel to the side walls 5. The air plate 11 forms two or more open air passages on the bottom of the ship. Each air passage is provided with a front valve 9 and a rear valve 13 with adjustable angles in the middle and aft of the ship to separate the bottom of the ship. Form two or more front air passages 4 and rear air passages 12 with one side open. At the bow bottom of each front air passage 4, there is a flared shape with a section larger than that of the front air passage 4 and a high angle of attack α. The air inlet 2.

[0025] The working and driving principle of the spacecraft: When the spacecraft is sailing in drainage, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com