Gasoline detergent additive

A gasoline detergent and main agent technology, applied in the petroleum industry, fuel additives, fuels, etc., to achieve the effects of quick start, improved power performance, and fuel saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

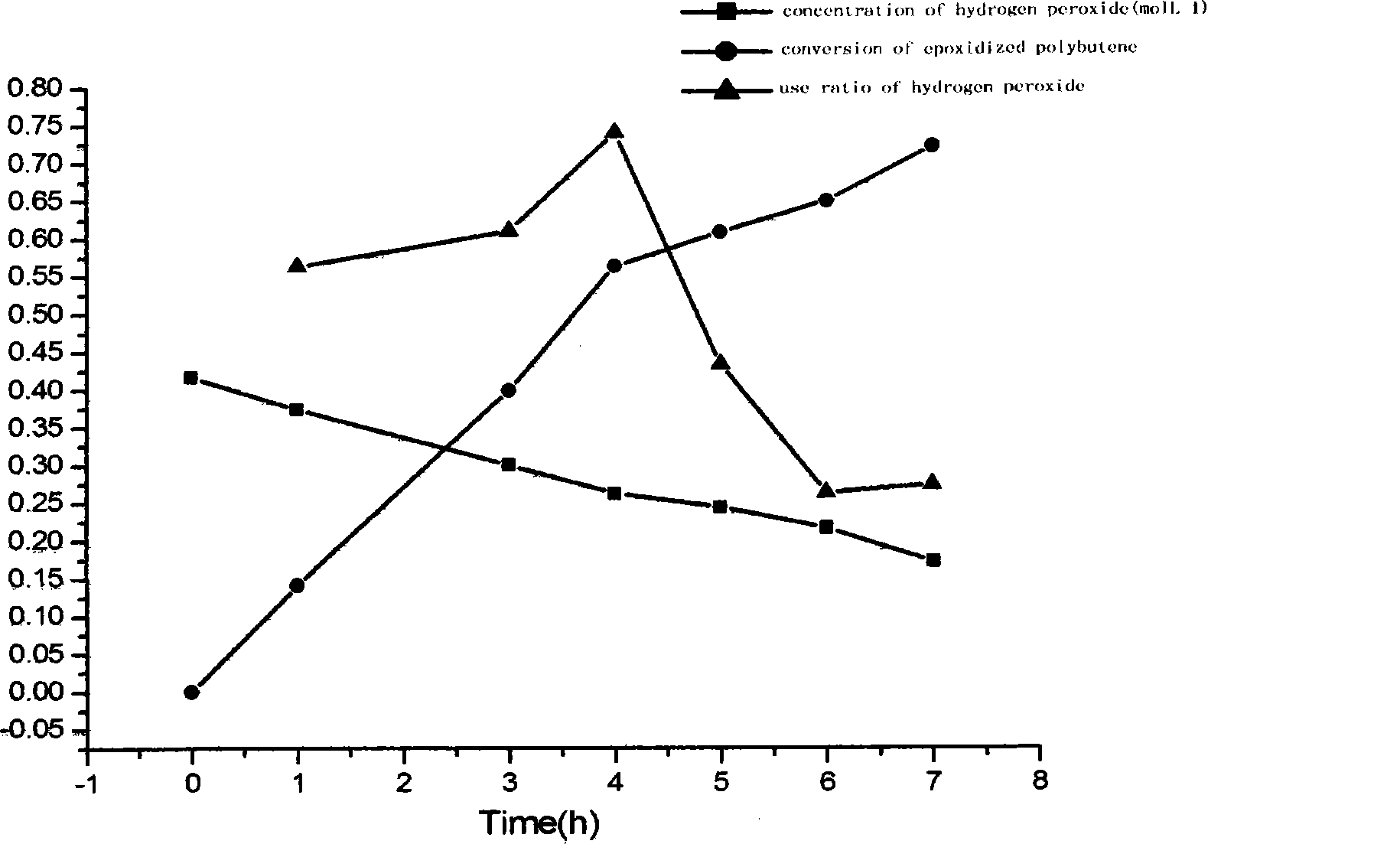

[0008] This specific embodiment adopts the following technical solutions: prepare boron-titanium molecular sieve catalysts on an industrial scale, use boron-titanium molecular sieves as catalysts, and hydrogen peroxide as an oxidant to prepare epoxy polyisobutylene with high yield; Under low pressure, direct aminolysis to obtain polyisobutene amine. Epoxy polyisobutylene is an important raw material for the synthesis of polyisobutylene amine. The conversion rate of epoxy polyisobutylene will directly affect the final conversion rate of polyisobutylene amine products, which in turn will affect the clean and dispersible performance of the product. Considering the terminal activity of polyisobutylene raw materials The group content is only 85%. In order to achieve a satisfactory cleaning and dispersion effect for the final product, the single-step conversion rate of the epoxidation reaction needs to reach more than 80%. Add hydrogen peroxide dropwise into a reaction kettle filled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com