Recycled asphalt microwave heating device

A microwave heating device and asphalt recycling technology, applied in roads, road repairs, roads, etc., can solve the problems of a large amount of toxic gas and smoke, heat loss, long heating time, etc., and achieve improved working conditions, improved uniformity, and heating speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

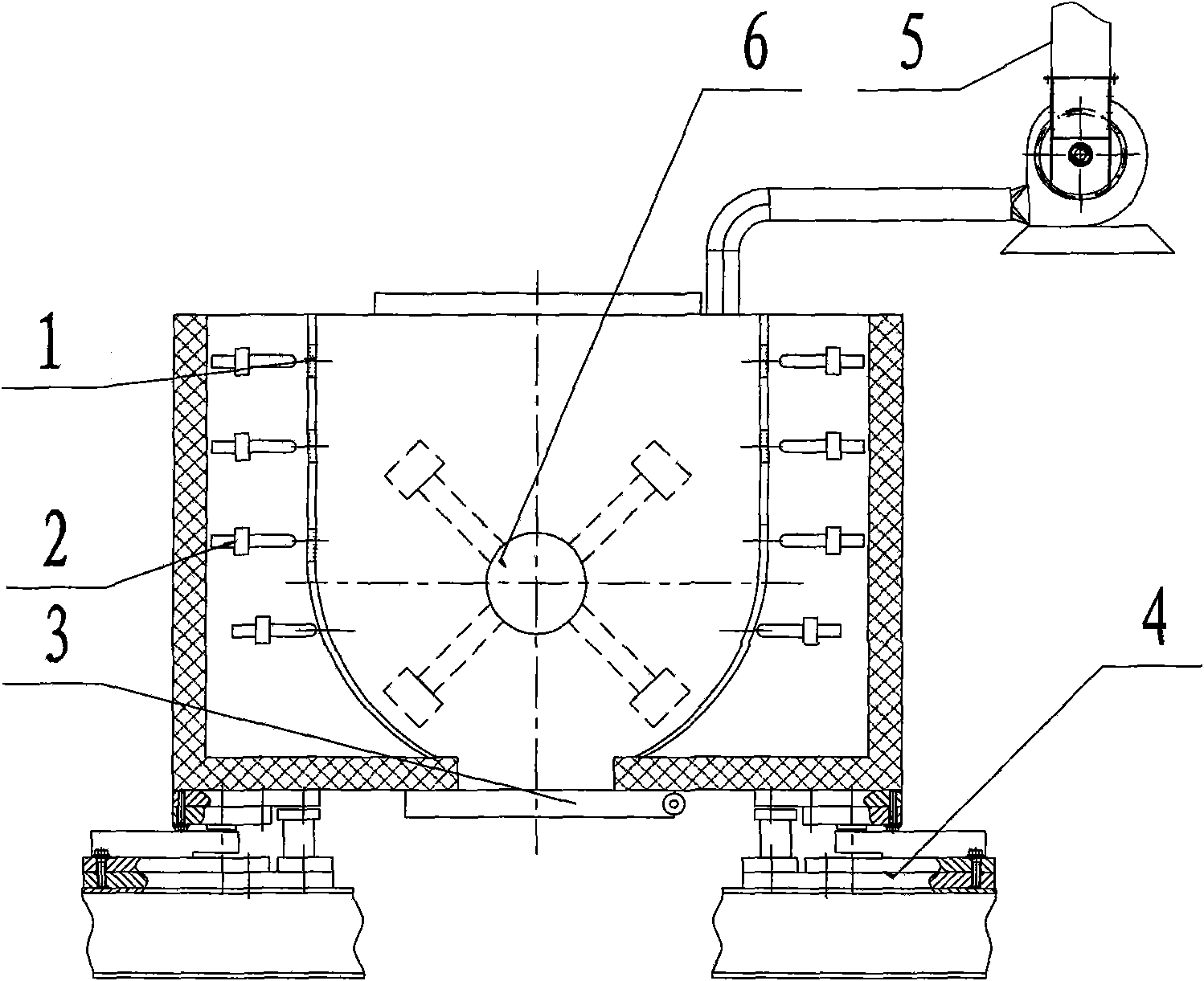

[0009] The microwave heating device for recovered asphalt is composed of a stirring shaft, a water vapor outlet, a load cell, a magnetron and a supporting waveguide. The stirring pot is a riveted weldment, the stirring pot is installed on the frame, the stirring arm and the stirring blade are installed on the stirring shaft as machine-added parts; there is an anti-flow groove structure around the furnace door of the microwave weighing and heating system. The anti-flow tank is a special-shaped tank structure set in the door; there is a ceramic window on the side wall of the cylinder, and the microwave is generated by the magnetron; the current signal collected by the infrared thermometer is A / D converted and converted into PLC Recognizable temperature digital signal; reducer, bearing, load cell, magnetron can be selected according to the specific conditions of the heating device.

[0010] Microwave heating principle: Microwave means that the frequency is 300~300×10 3 MHz elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com