Fuel or gas molten salt furnace

A molten salt furnace and gas technology, applied in the field of oil-fired gas molten salt furnace, can solve the problem that ordinary heating facilities cannot provide high temperature above 300 ℃, and achieve the effect of improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

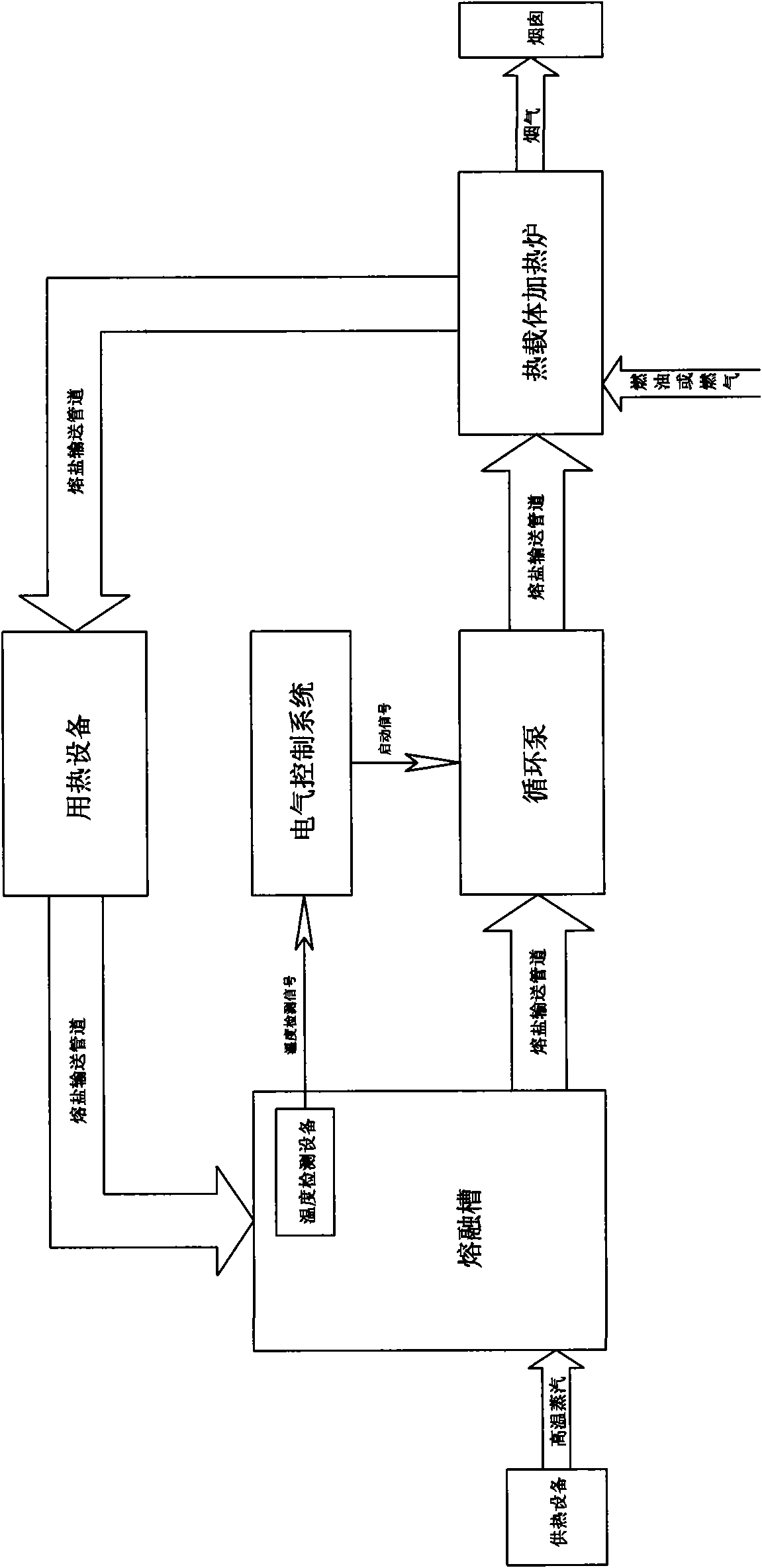

[0007] The working process of the present invention is as follows: the mixed inorganic salt powder particles are added into the melting tank, and under the heating of the high-temperature steam introduced in the melting tank, the temperature in the melting tank reaches 142°C, and the mixed inorganic salt powder particles Melted into liquid, the temperature detection device installed in the melting tank detects that the temperature reaches the melting temperature of the inorganic salt, and returns an electrical signal to the electrical control system. After receiving the electrical signal, the electrical control system sends a signal to start the circulation pump. signal, the circulating pump starts to work, and the power generated during the working process of the circulating pump presses the mixed inorganic salt in the melting state into the delivery pipeline, and transports it to the heat carrier heating furnace to continue heating. The heating furnace of the present invention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com