Adjustable electronic detonator control chip and flow for controlling same

A technology of electronic detonator and control chip, which is applied in the field of pyrotechnics manufacturing, can solve the problems of increasing the volume and cost of electronic detonators, affecting the delay accuracy of electronic detonators, and the explosion impact of unexploded detonators, so as to improve the flexibility of use and reliability. Integrated, reliable ignition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0100] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

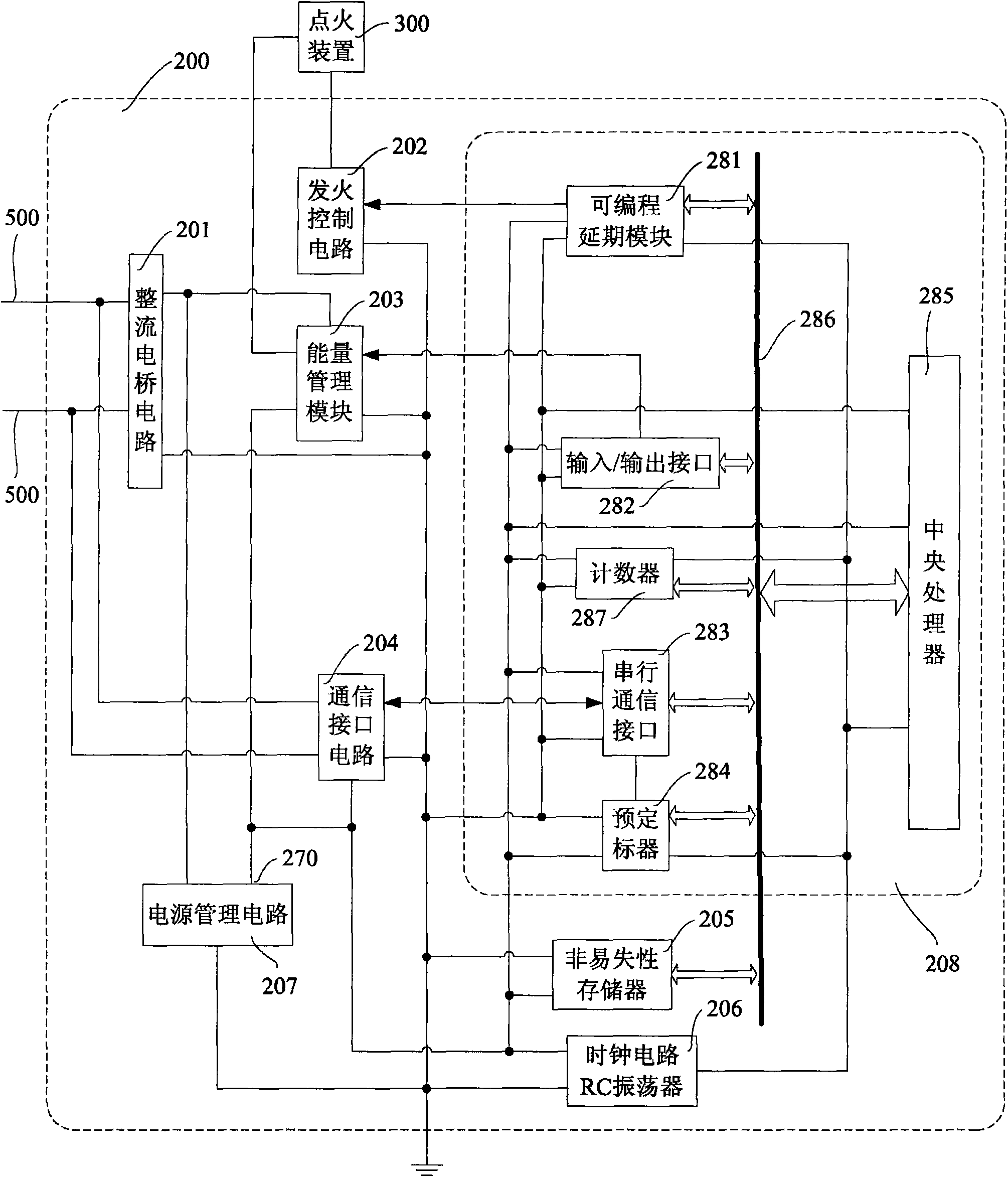

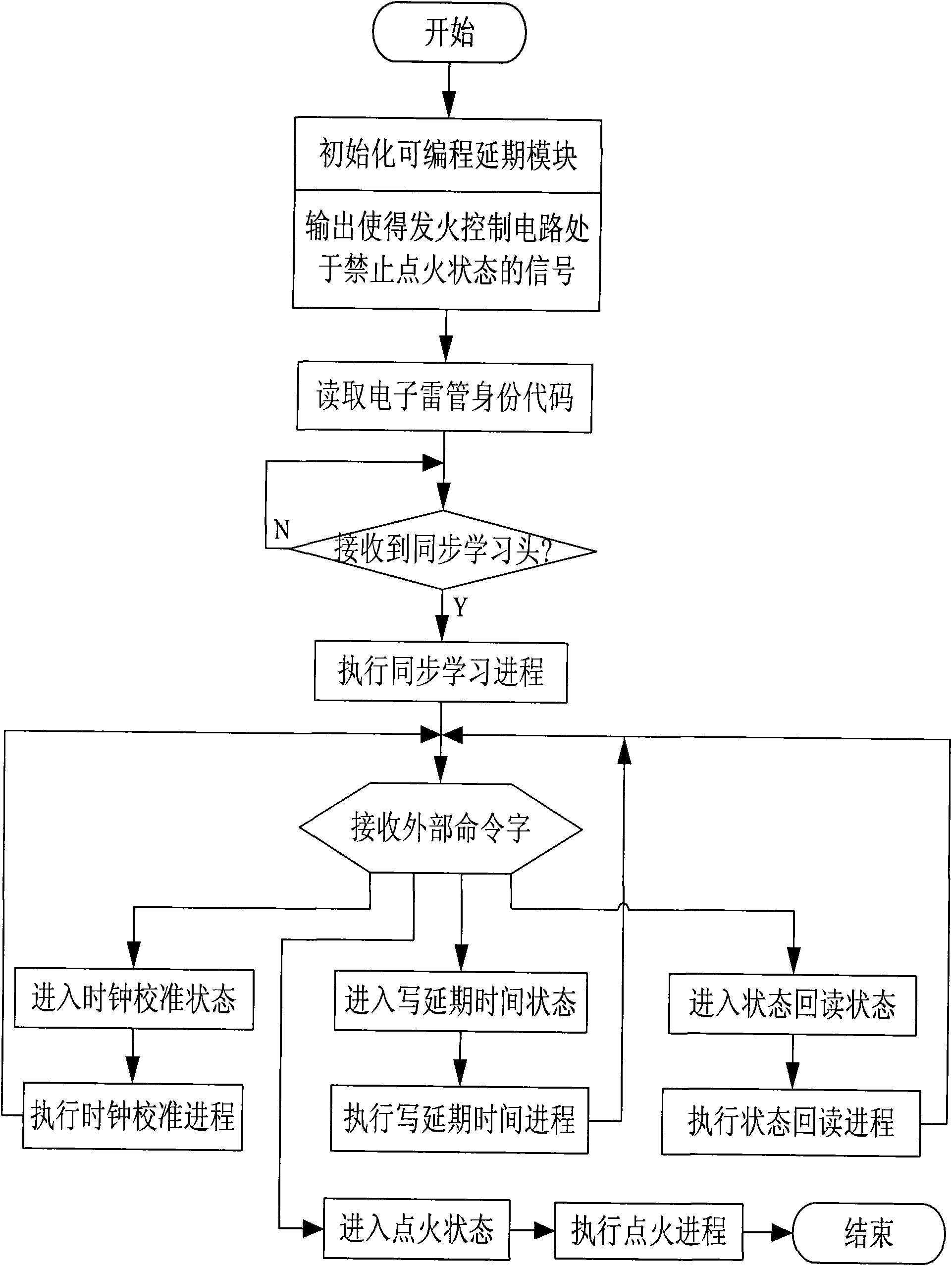

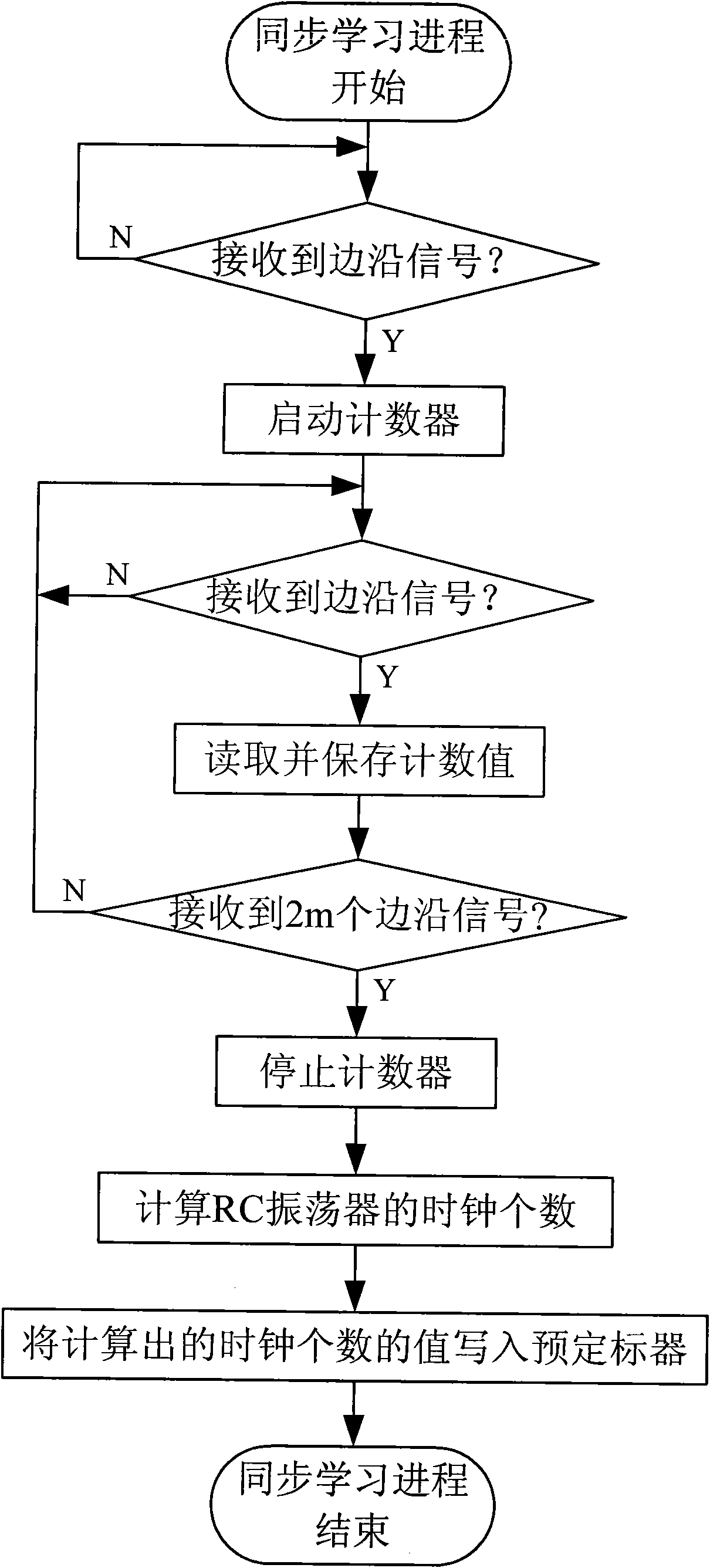

[0101] The present invention further improves on the basis of the patent application document 200810211374.2, and provides a calibrated electronic detonator control chip 200, such as figure 1 , including a rectifier bridge circuit 201 , an ignition control circuit 202 , an energy management module 203 , a communication interface circuit 204 , a power management circuit 207 , a nonvolatile memory 205 , a clock circuit, and a logic control circuit 208 . Wherein, the logic control circuit 208 includes a programmable delay module 281 , an input / output interface 282 , a serial communication interface 283 , a prescaler 284 , and a central processing unit 285 . One end of the clock circuit is grounded, one end is connected to the power output end 270 of the power management circuit 207 , and the other end is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com