Method for forming and capturing liquid drops based on three-layer sandwich disc-type chip and application thereof

A disc-type, chip-based technology, applied in chemical instruments and methods, laboratory containers, dissolution, etc., can solve the problems of droplet size change, uncapturable, and droplet cannot enter the capture area, etc., to achieve capture efficiency High, avoid the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

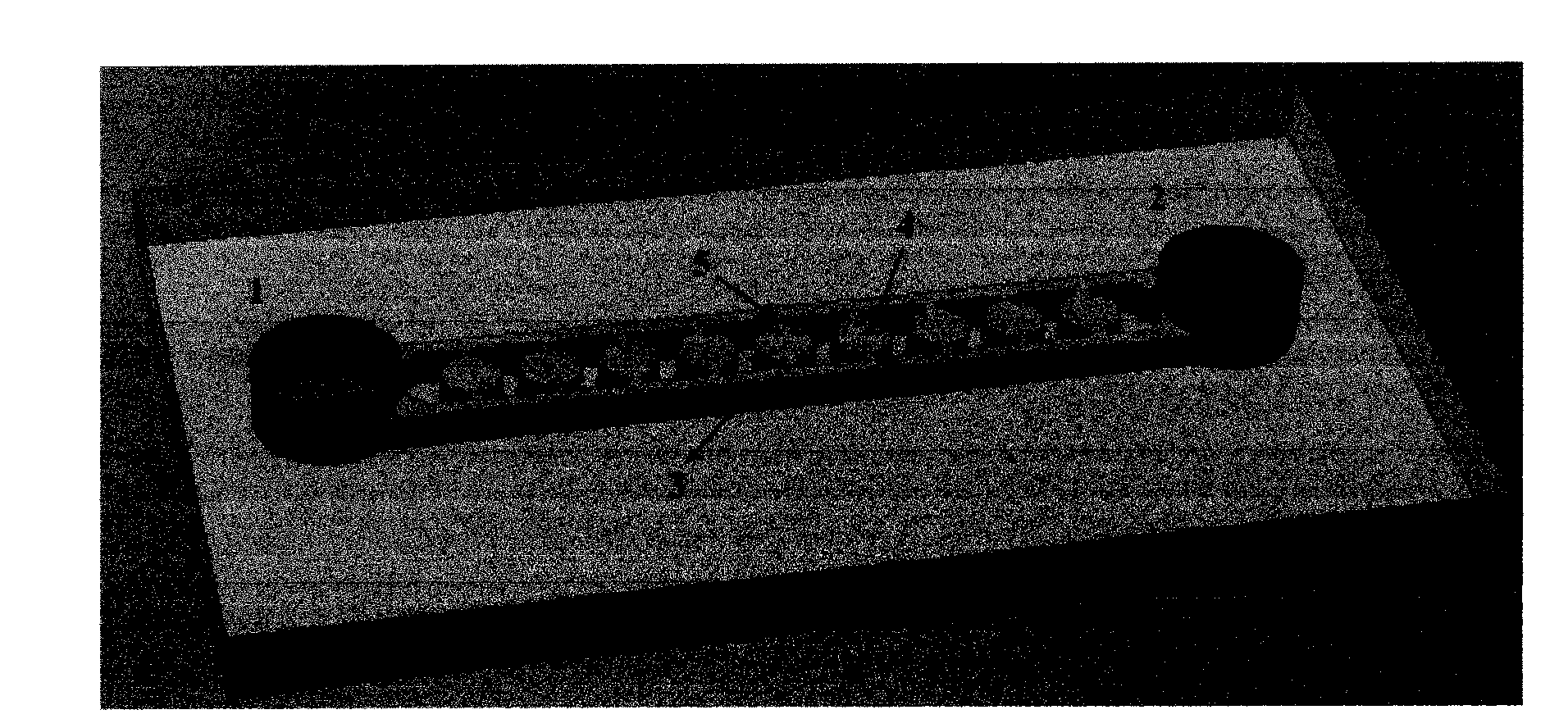

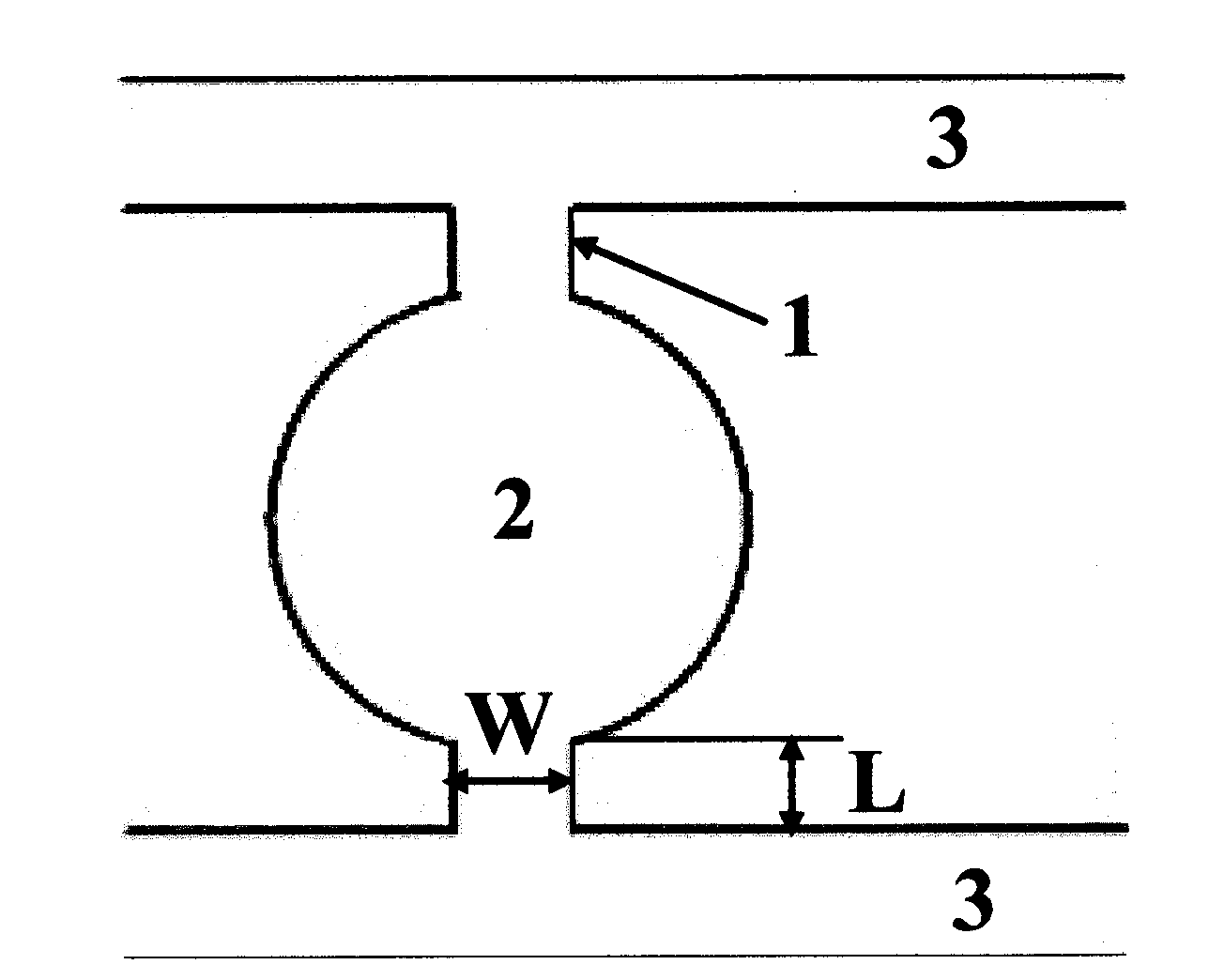

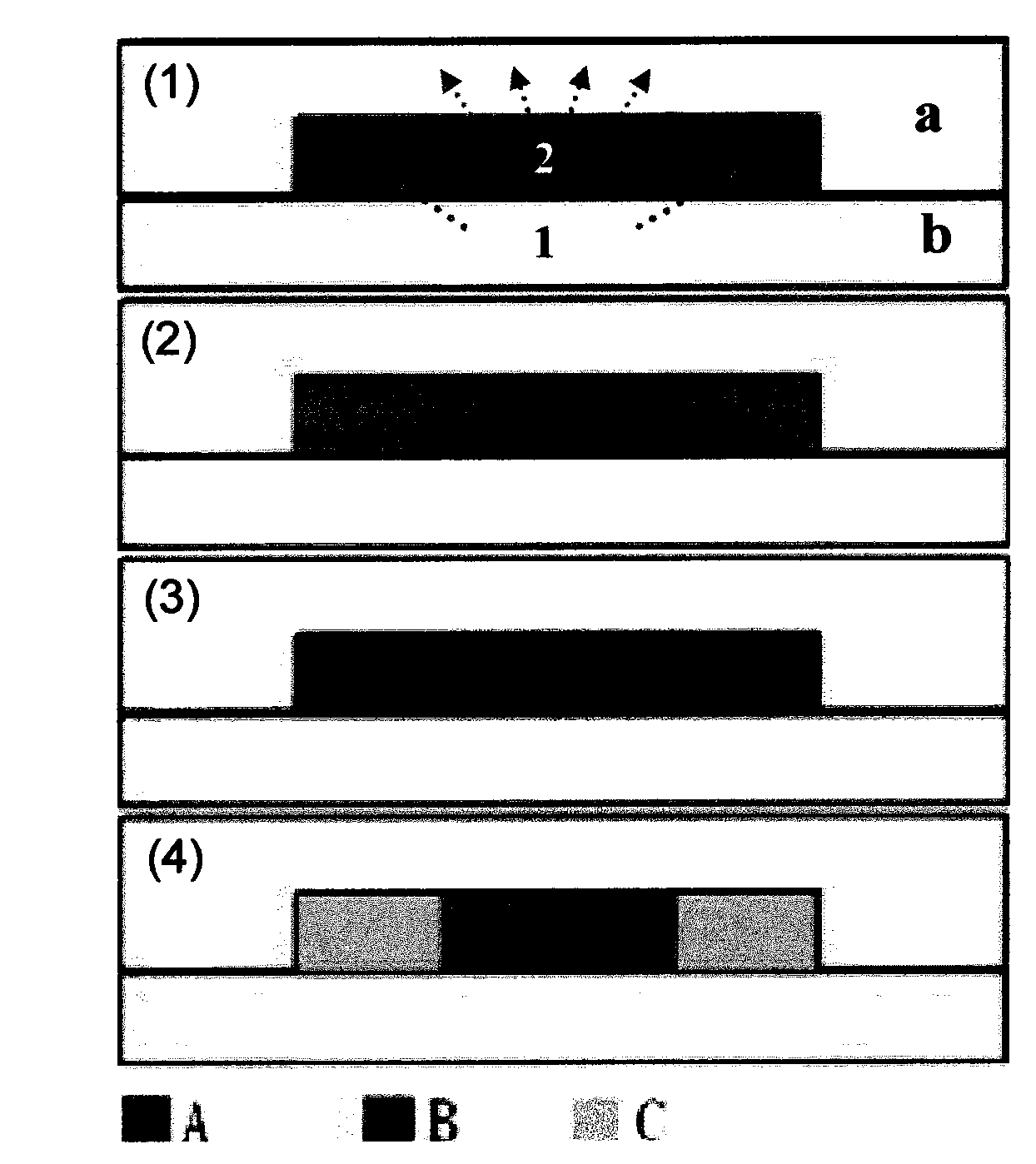

[0040] Example 1 In Situ Formation and Capture of Arrayed Droplets

[0041] Will figure 1 Put the PDMS chip shown in a vacuum desiccator and degas it in vacuum for 3-5 minutes. After taking it out, add methylene blue aqueous solution in reservoir 1, and pump it with a vacuum pump in reservoir 2. The methylene blue aqueous solution fills the main channel and forms a trap. area of air bubbles (see Figure 3-1 , 4-1), due to the gas permeability of PDMS, the air in the capture area slowly enters the PDMS body, and the methylene blue solution in the main channel gradually fills the capture area (see Figure 3-2 , Figure 4-2 ), after the subunit blue solution is completely filled with the capture area, the subunit blue solution in the main channel is evacuated in the reservoir 2, and the subunit blue solution in the capture area forms water droplets (see Figure 3-3 , Figure 4-3 ), and then add mineral oil to the reservoir 1, the mineral oil fills the main channel under cap...

Embodiment 2

[0042] Example 2 Formation of pH Gradients in Array Droplets

[0043] Will Figure 8 Put the three-layer sandwich disc chip shown in a vacuum desiccator and degas it for 3-5 minutes. After taking it out, add pH indicator solution to the liquid storage tank near the center of the circle, and use a vacuum pump to pump the liquid storage tank away from the center of the circle. After a while, the pH indicator solution enters the main channel, and wait until the pH indicator solution fills the capture area, then centrifuge the chip for 55 seconds (2500 rpm), and then add Fc40 (fluorinated oil) to the reservoir near the center of the circle respectively, Formation of Fc40-coated pH indicator droplets. Ammonia gas is continuously fed into the lower channel, and the ammonia gas diffused across the membrane reacts with the pH indicator solution, resulting in a change in the color of the pH indicator solution (see Figure 9 ). Due to the absorption of ammonia gas by the pH indicator...

Embodiment 3

[0044] Example 3 Coordination reaction of various metal ions and ammonia gas in the array droplet

[0045] use Figure 8 The chip shown and the method described in embodiment 2 form NiCl respectively 2 / Fc40, CuSO 4 / Fc40 and Fe(NO 3 ) 3 / Fc40 array droplets, ammonia gas is continuously fed into the lower channel, the ammonia gas diffused across the membrane is absorbed by the metal salt solution, and reacts with metal ions, the amount of ammonia gas absorbed by each droplet is different, resulting in the formation of metal ions -Crystals of ammonia gas complexes (see Figure 10-3 , 10-4), solution, precipitation and other different forms (see Figure 10 , 11, 12).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com