Iron making method using direct reduction-grinding screening to treat copper slag and nickel slag

A copper slag, direct technology, applied in the ironmaking field of direct reduction-grinding treatment of copper slag and nickel slag, can solve problems such as lack of advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

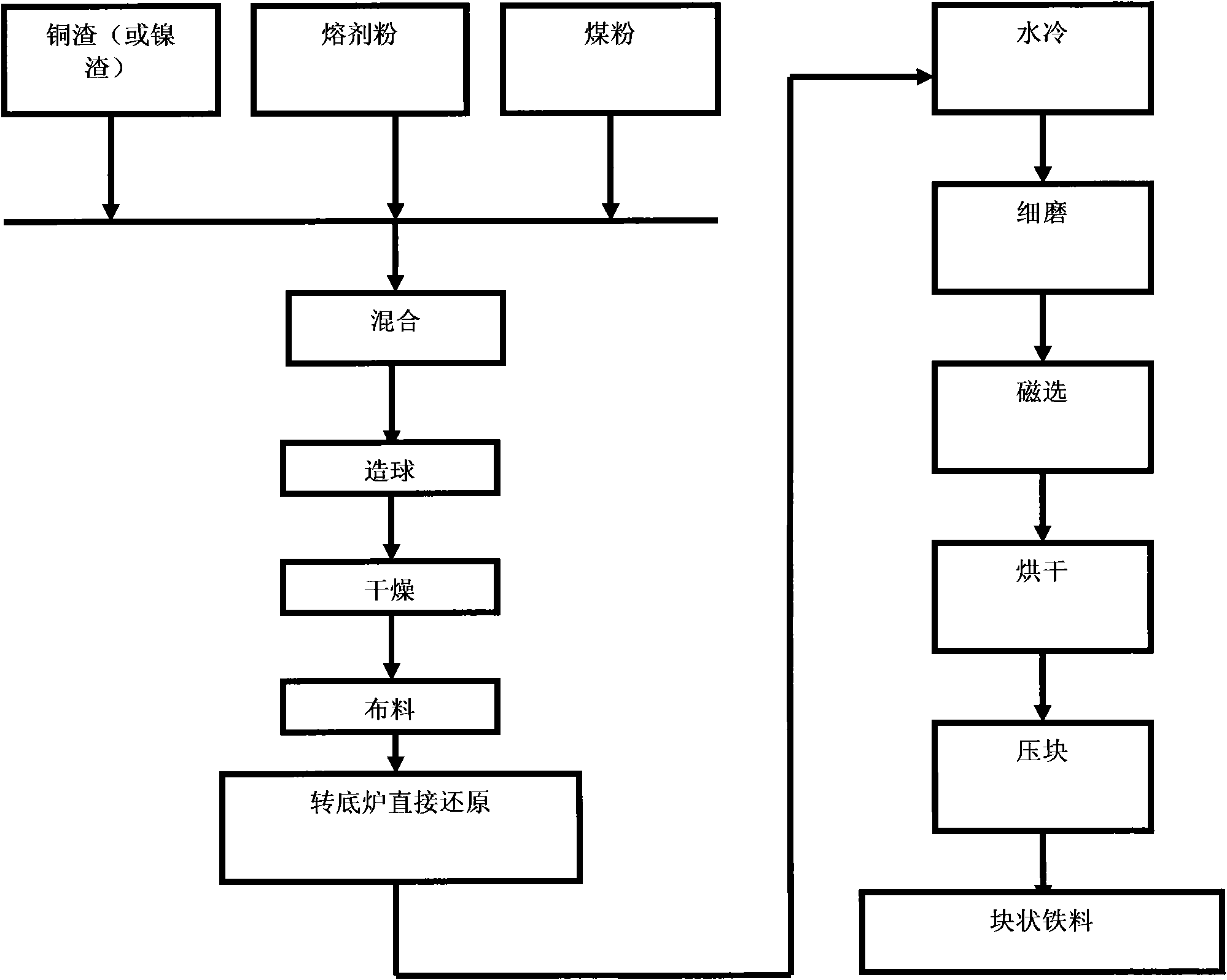

Method used

Image

Examples

specific Embodiment

[0026] Mix the copper slag containing 40% iron in a certain place according to the ratio of copper slag: coal: limestone = 100: 20: 15, put it into the rotary hearth furnace and roast it for 30 minutes, then immediately immerse it in water to cool it, and go through crushing and magnetic separation. After agglomeration, a direct reduced iron block containing 94% of iron and 1.5% of copper is obtained, and the yield of iron in the copper slag is 90%. For every ton of iron block produced, 2.5 tons of copper slag, 0.375 tons of limestone, 0.75 tons of fuel and 400kwh of electricity are consumed.

[0027] In the present invention, the high-temperature reduction process of the rotary hearth furnace is used to reduce the iron in the copper slag or nickel slag, and after quenching, the difference in expansion coefficient between the iron crystal and the gangue is used to loosen the combination of the two, and then wet Grinding and analysis; using oxygen-deficient high-temperature exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com