Comprehensive controlling method and comprehensive controlling system for temperature field and air pressure field of grate bed of grate

A comprehensive control, chain grate technology, applied in the furnace type, waste heat treatment, furnace and other directions, can solve the problems of increasing water vapor content, poor drying effect of pellets, too fast temperature rise, etc., to extend service life, real-time control Ease of use and the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

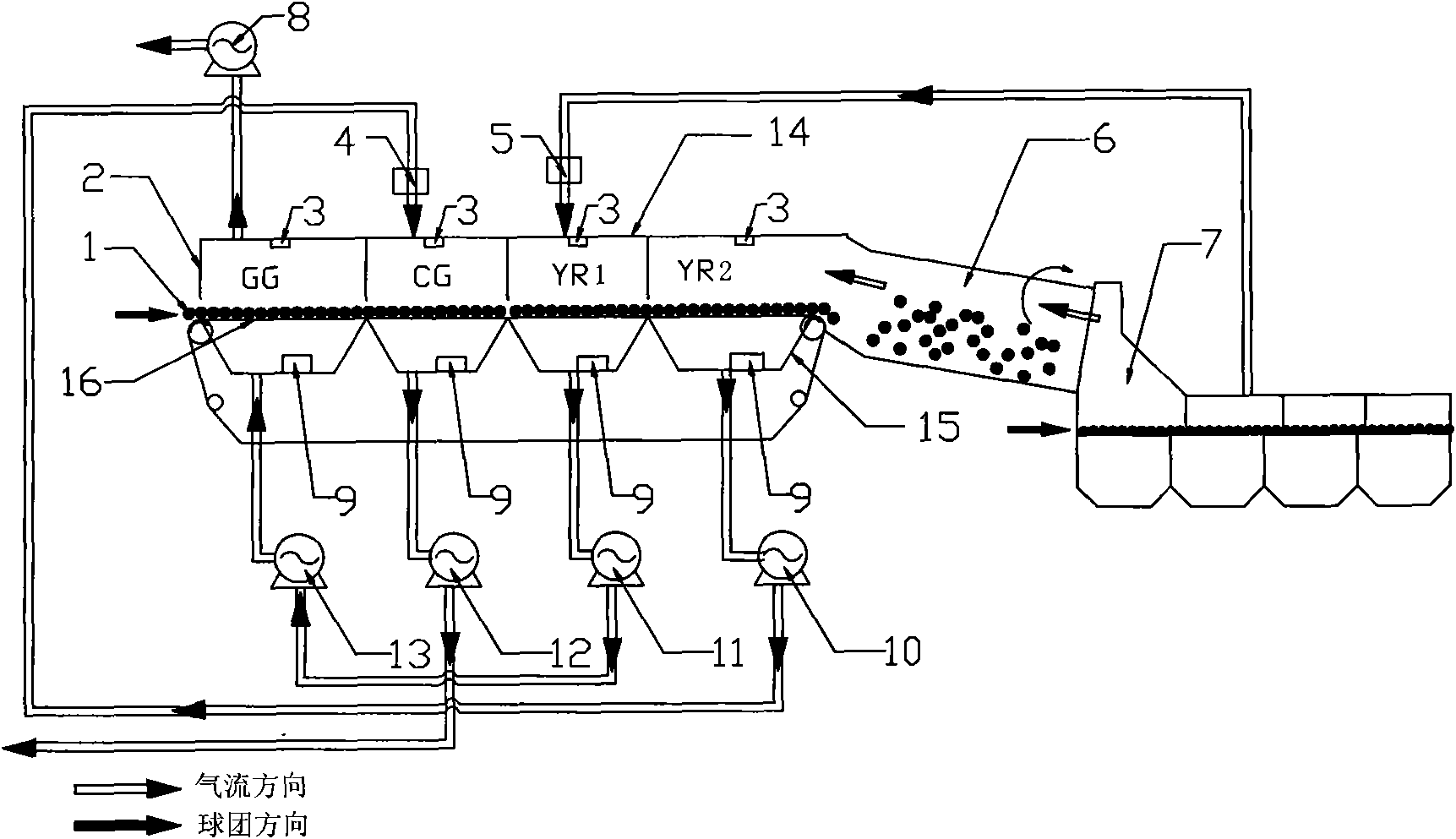

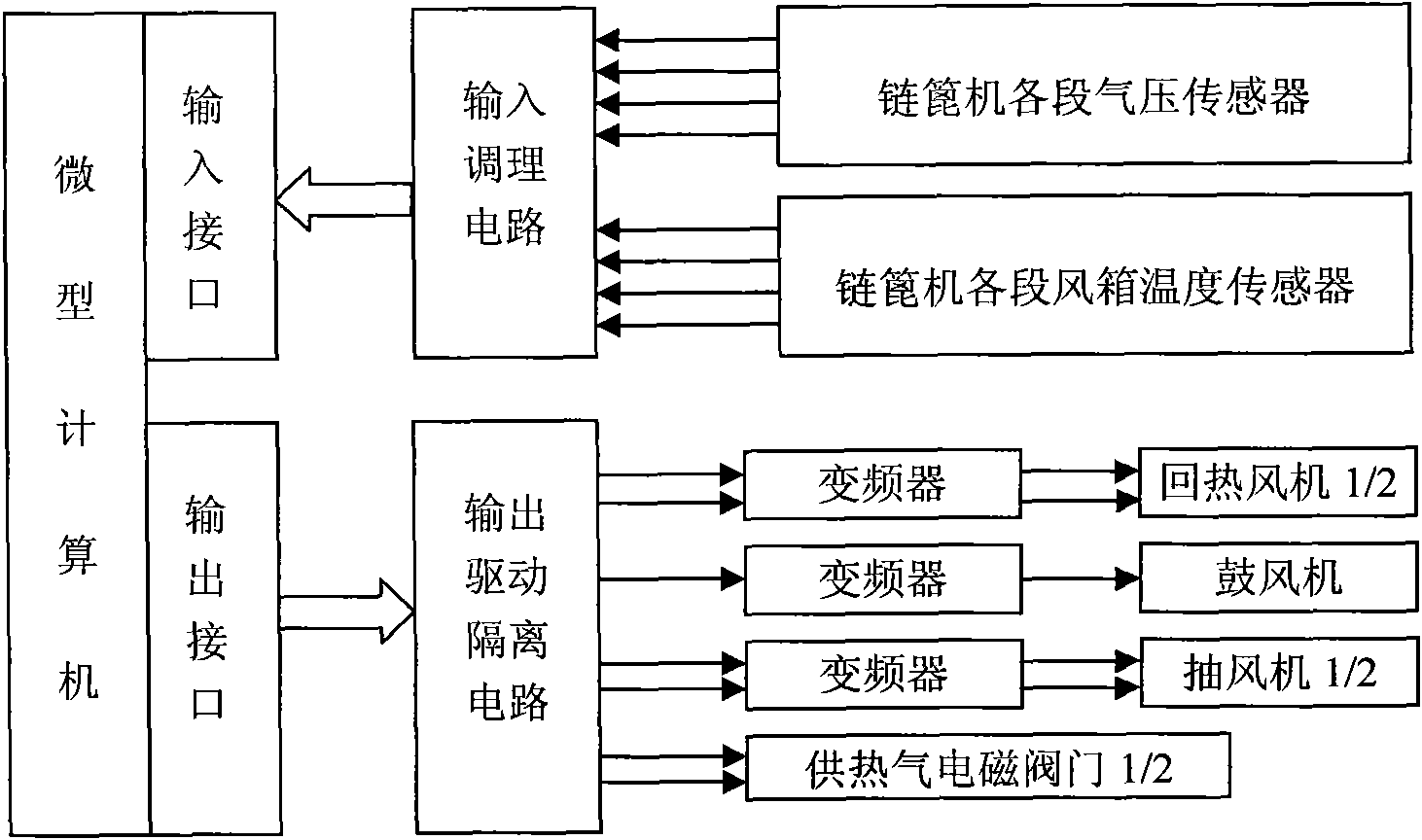

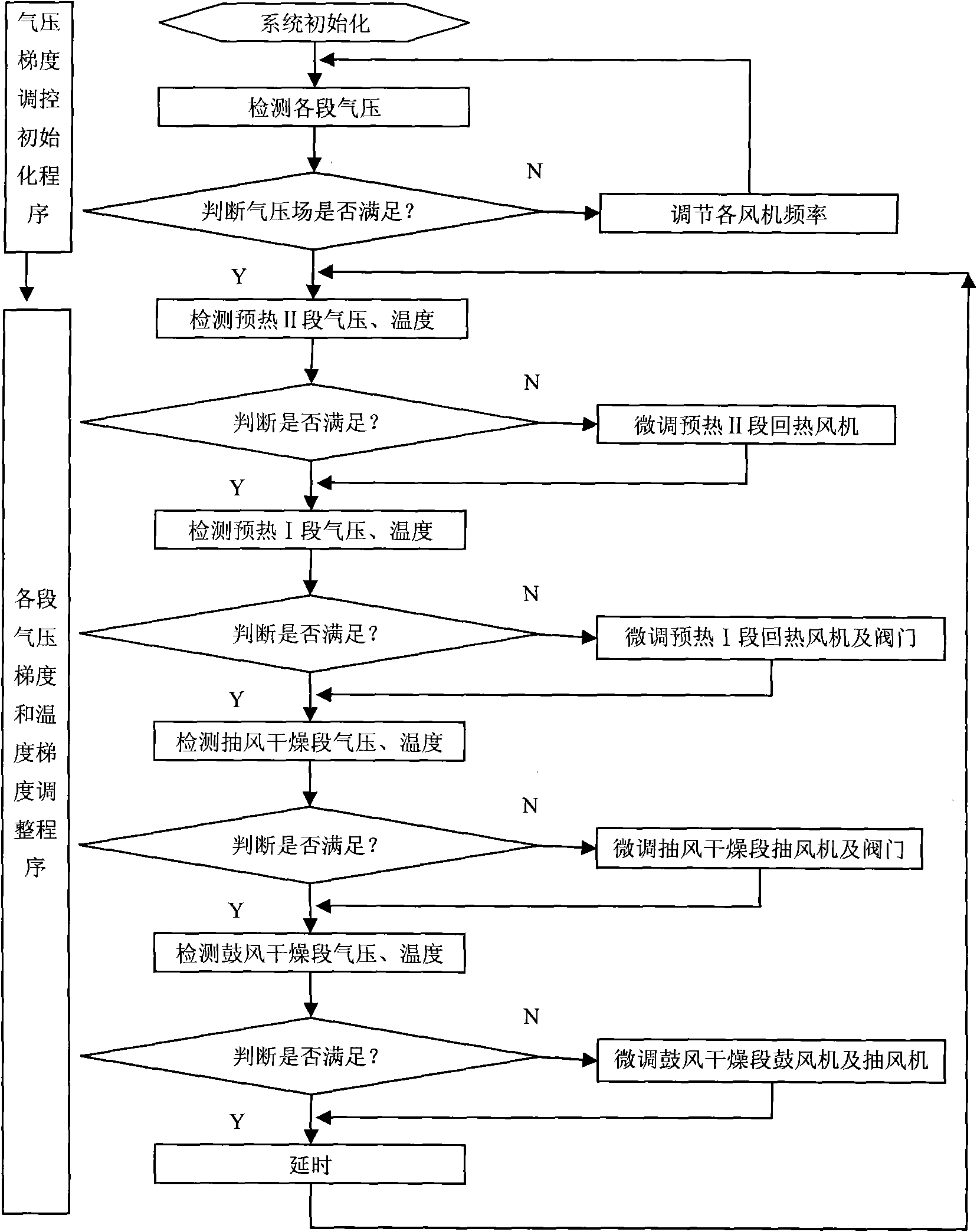

[0027] Such as figure 1As shown, the produced green pellets 1 pass through the grate bed 16 of the grate machine 2, respectively pass through the blast drying section GG, the draft drying section CG, the preheating I section YR1 and the preheating II section YR2, to the rotary kiln 6, and pass through Coal injection is roasted at high temperature to obtain cooked pellets 1, which are sent to the ring cooler 7, circulated and cooled to near normal temperature, and then sent to the blast furnace. Air pressure sensors 3 are respectively installed in the four sections of wind hoods 14 above the grate machine 2, and exhaust fans 8, heating gas are respectively connected on the wind hoods 14 of the blast drying section GG, the exhaust drying section CG, and the preheating section YR1. Electromagnetic valves 4 and 5 are respectively equipped with temperature sensors 9 in the four-stage bellows 15 below the grate 2, and on the bellows 15 of the blast drying section GG, the draft dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com