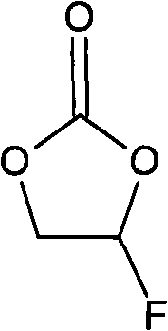

Method for purifying fluoroethylene carbonate

A technology of ethylene carbonate and a purification method, which is applied in the field of preparation of fluoroethylene carbonate, can solve problems such as unsatisfactory fluoroethylene carbonate, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] According to the preparation method of fluoroethylene carbonate of this embodiment, the specific process is as follows:

[0018] Add 880 grams of ethylene carbonate (content 99wt%) into a 2000ml stainless steel pressure vessel, install a 5W ultraviolet lamp, connect a stainless steel air duct and exhaust gas absorption device, heat up to 40°C, and feed 660g in a volume ratio of 1: 1 fluorine / nitrogen mixed gas, after the gas is introduced, 1011 g of crude fluoroethylene carbonate is obtained, wherein the content of fluoroethylene carbonate is 52.30 wt%, and the acidity of the crude product is 0.23%.

Embodiment 2

[0020] According to the preparation method of fluoroethylene carbonate of this embodiment, the specific process is as follows:

[0021] In a 5000ml four-necked flask, equipped with a stirrer and condenser, add 1680g of sodium fluoride, 3000ml of dimethyl carbonate and 5g of tetrabutylammonium bromide, stir, heat to 60℃, and drop 1225g of dimethyl carbonate. After the reaction is completed, the dimethyl carbonate is removed by distillation under reduced pressure to obtain 980 g of crude fluoroethylene carbonate, wherein the content of fluoroethylene carbonate is 75.62 wt%, and the acidity of the crude product is 1.3%.

Embodiment 3

[0023] According to the following unified method, 50g of the crude fluoroethylene carbonate obtained in Example 1 was recrystallized in a mixed solvent of different proportions of toluene and n-hexane at a temperature of -10°C, and then reduced under a vacuum of 665Pa-1064Pa Pressure distillation, collect the 84-85 ℃ fluoroethylene carbonate fraction as the product, the ratio of the mixed solvent, the amount, and the purity and acidity value of the product are shown in Table 1 on page 3 of the manual.

[0024] Table 1

[0025] Toluene (g)

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com