Method for degrading lignocellulose and special cellulose degradation bacteria thereof

A technology of cellulolytic bacteria and lignocellulose, applied in the direction of microorganism-based methods, biochemical equipment and methods, applications, etc., can solve the problems of obtaining sample microbial population information and the difficulty of pure culture of microorganisms, so as to promote animal husbandry Development, significant economic value and social significance, effect of maintaining soil fertility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

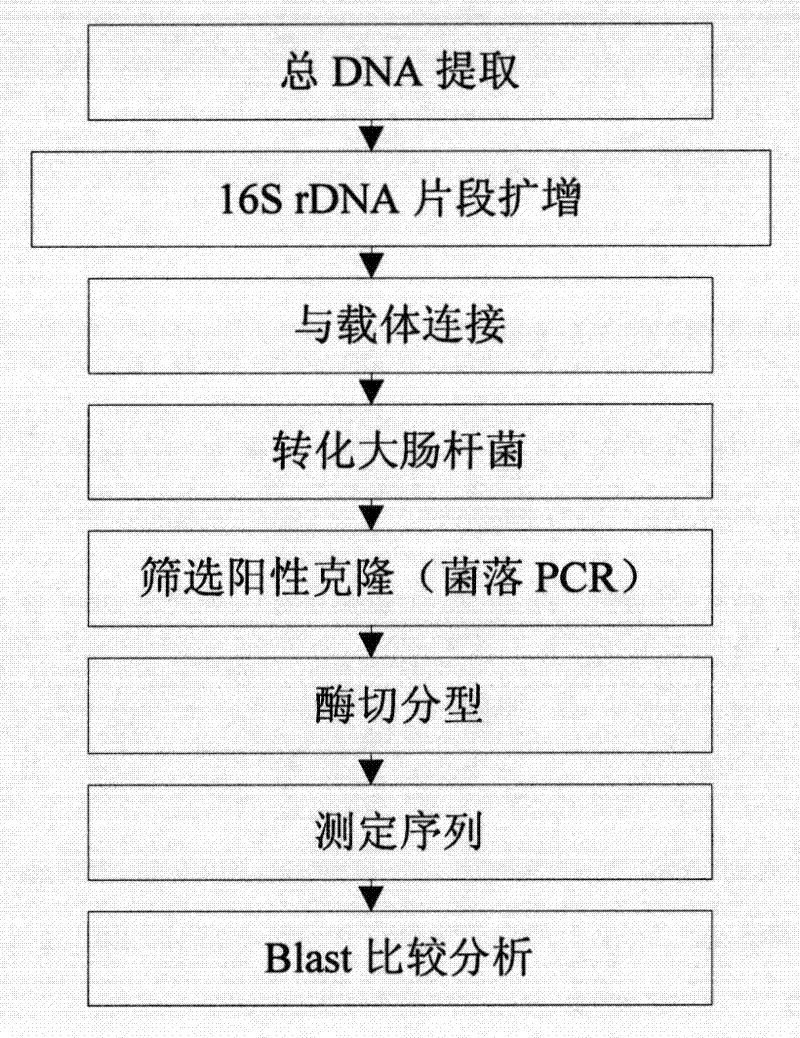

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1, the acquisition of cellulolytic strain L-C

[0025] Each liter of medium contains the following components: yeast extract, 2g; tryptone, 2g; NaCl, 18g; KCl, 1g; MgSO 4 ·7H 2 O, 6g; MgCl 2 ·6H 2 O, 4g; CaCl 2 ·H 2 O, 1.5g; NaHCO 3 , 0.7g; pH7.2.

[0026] Weigh the remaining corresponding medicine in proportion and pour it into a beaker filled with some tap water in advance. After the medicine is fully dissolved, use tap water to set the volume to 990ml, adjust the pH to 7.2, and finally set the volume to 1000ml.

[0027] Distribute each 10ml of culture medium into 18×180mm common test tubes (with 12×100mm filter paper strips placed in advance).

[0028] 1. Acquisition of cellulolytic strain L-C

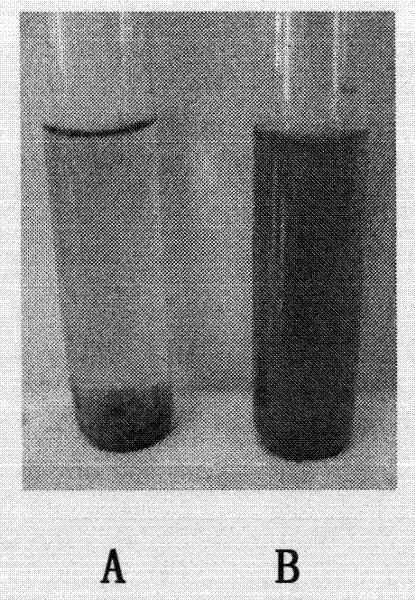

[0029] Inoculate 0.2-0.6 anaerobic activated sludge samples collected from Guangxi cassava alcohol waste liquid UASB-TLP treatment system into test tubes containing medium. The test tubes were shaken and cultured at a temperature of 40-50° C. at a speed of...

Embodiment 2

[0074] Embodiment 2, the culture temperature optimization of cellulolytic strain L-C

[0075] Each liter of medium contains the following components: yeast extract, 2g; tryptone, 2g; NaCl, 18g; KCl, 1g; MgSO 4 ·7H 2 O, 6g; MgCl 2 ·6H 2 O, 4g; CaCl 2 ·H 2 O, 1.5g; NaHCO 3 , 0.7g; pH7.2.

[0076] The preparation method of the culture medium is as follows: Weigh the remaining corresponding medicine in proportion and pour it into a beaker filled with tap water in advance, after the medicine is fully dissolved, use tap water to adjust the volume to 990ml, adjust the pH to 7.2, and finally adjust the volume to 1000ml.

[0077] Distribute each 10ml of culture medium into 18×180mm common test tubes (with 12×100mm filter paper strips placed in advance).

[0078] The cellulolytic strain L-C obtained in step 1 of Example 1 was inoculated into test tubes containing culture medium, the inoculum amount was 5% (volume percentage), and 40 test tubes were inoculated. The 40 samples wer...

Embodiment 3

[0080] Embodiment 3, cellulolytic strain L-C degrades lignocellulose

[0081] Each liter of medium contains the following components: yeast extract, 1g; tryptone, 1g; NaCl, 10g; KCl, 0.3g; MgSO 4 ·7H 2 O, 3g; MgCl 2 ·6H 2 O, 2g; CaCl 2 ·H 2 O, 0.5g; NaHCO 3 , 0.2g.

[0082] The preparation method of the culture medium is as follows: Weigh the remaining corresponding medicine in proportion and pour it into a beaker filled with tap water in advance. After the medicine is fully dissolved, use tap water to adjust the volume to 990ml, adjust the pH to 6.8, and finally adjust the volume to 1000ml.

[0083] Distribute each 10ml of culture medium into 18×180mm common test tubes.

[0084] Take 60 test tubes filled with culture medium and divide them into six groups, 10 in each group. Add dried straw to the first and second test tubes (add 0.1 g dried straw to each test tube), add dried bagasse to the third and fourth test tubes (add 0.3 g to each test tube bagasse), place 0.3g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com