A kind of colloid bacillus and the method for using its solid-state fermentation to prepare bio-organic fertilizer

A technology of Bacillus colloid and bio-organic fertilizer, applied in the field of agricultural microorganisms, can solve the problems of industry development obstacles, thick fermentation liquid, difficult concentration and drying, etc., to achieve the effects of balancing the ecosystem, maintaining fertility and improving the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

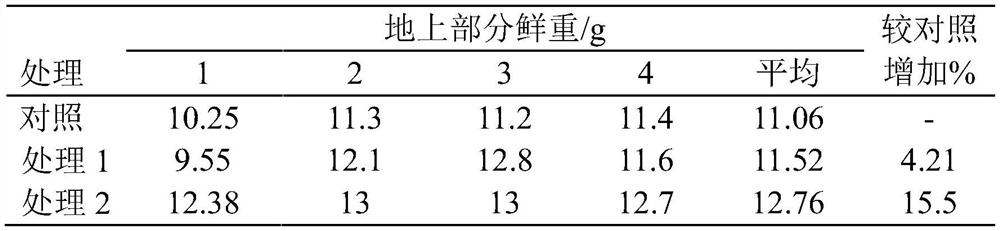

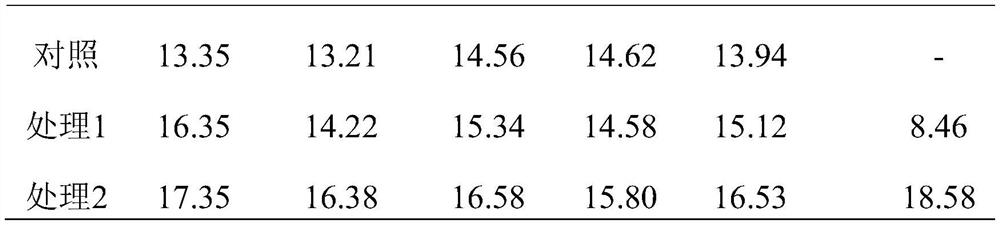

Examples

Embodiment 1

[0023] Isolation of Potassium Solubilizing Bacteria

[0024] The separation process is usually the following steps:

[0025] The first step is to prepare Alexander Borov medium: its components include: Na 2 HPO 4 2g, FeCl 3 0.005g, MgSO4 7H 2 O 0.5g, CaCO 3 0.1g, 3g sucrose, 1g potassium feldspar powder (washed five times with deionized water), 1000mL distilled water, pH 7.0, 20g agar, sterilized at 121°C for 20min.

[0026] The second step is the primary screening of potassium-solubilizing bacteria: inoculate the enrichment on the solid medium of Alexander Borov medium and place it in a constant temperature incubator at 37°C for 10 days, and observe whether there is a transparent ring formed on the medium and its size. Use a ruler to measure the diameter of the hydrolysis zone and the colony, and the relative size of the potassium-separating ability of the strain can be judged according to the diameter ratio of the hydrolysis zone and the colony zone. Pick the strain...

Embodiment 2

[0028] Molecular Identification of 16S rDNA Sequence of Strain M-1

[0029] Genomic DNA of strain QF-101 was extracted by Chelex method, and the 16S rDNA gene of strain QF-101 genomic DNA was completely analyzed by using 16S rDNA universal primers 27F (5'-AGAGTTTGATCMTGGCTCAG-3') and 1492R (5'-GGTTACCTTGTTACGACTT-3'). Long sequences were amplified by PCR. The PCR product was subjected to 1% agarose gel electrophoresis, and after the target band was cut, the target DNA fragment was recovered using the SanPrep Column DNA Gel Recovery Kit (SangonBiotech, Order No. B518131). 3730xl DNA Analyzer (Applied Biosystems) was used for sequence analysis of DNA fragments, and the sequencing kit used BigDyeTerminator v3.1 (Applied Biosystems).

[0030] The bidirectional sequencing results were spliced using SeqMan (DNASTAR Lasergene) to obtain a nearly full-length 16SrRNA gene sequence. Using EzBioCloud Identify service (https: / / www.ezbiocloud.net / identify) and NCBI Nucleotide BLAST (ht...

Embodiment 3

[0033] Qualitative Test of Potassium Solubilizing Ability of Strain M-1

[0034] Cultivate the culture medium of strain M-1, the volume of liquid in a 250mL Erlenmeyer flask is 50mL, cultivate for 48h, and use the fermentation broth sterilized at 121°C for 30min as a blank control. Weigh 12.5g of potassium feldspar powder, add it to the culture medium and the inactivated culture medium respectively, do 3 parallels for each treatment, culture at 37°C and 160rpm, and use potassium tetraphenylborate on the 5th and 10th day The content of soluble potassium was determined gravimetrically.

[0035] Table 1 Qualitative test of strain M-1's ability to decompose potassium

[0036] 5-day potassium solution (mg / L) 10-day potassium solution (mg / L) blank control 2.381 4.912 Strain M-1 30.735 58.975

[0037] The bacterial strain has been preserved in the General Microorganism Center of China Committee for Culture Collection of Microorganisms, the preservatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com