Laser evaporation multi-cavity nano-powder preparation device

A laser evaporation, multi-cavity technology, applied in the direction of nano-carbon, carbon nanotubes, inorganic chemistry, etc., can solve the problems of insufficient continuity, low production efficiency, and increased cost, so as to reduce the time of vacuuming and avoid large-scale production stoppage , to avoid the effect of device deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

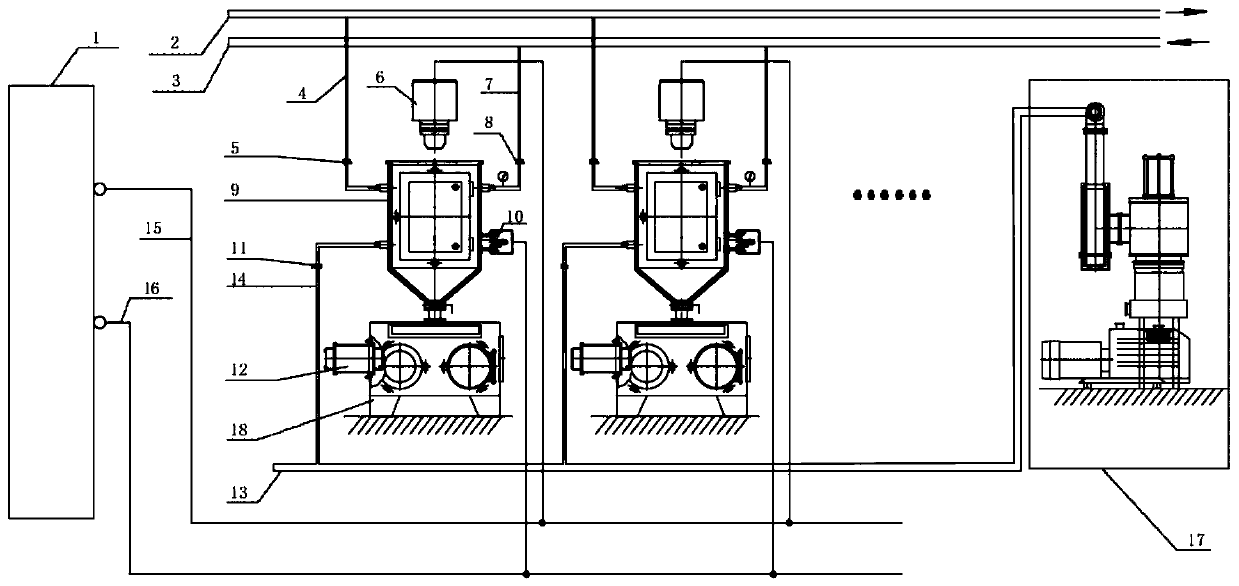

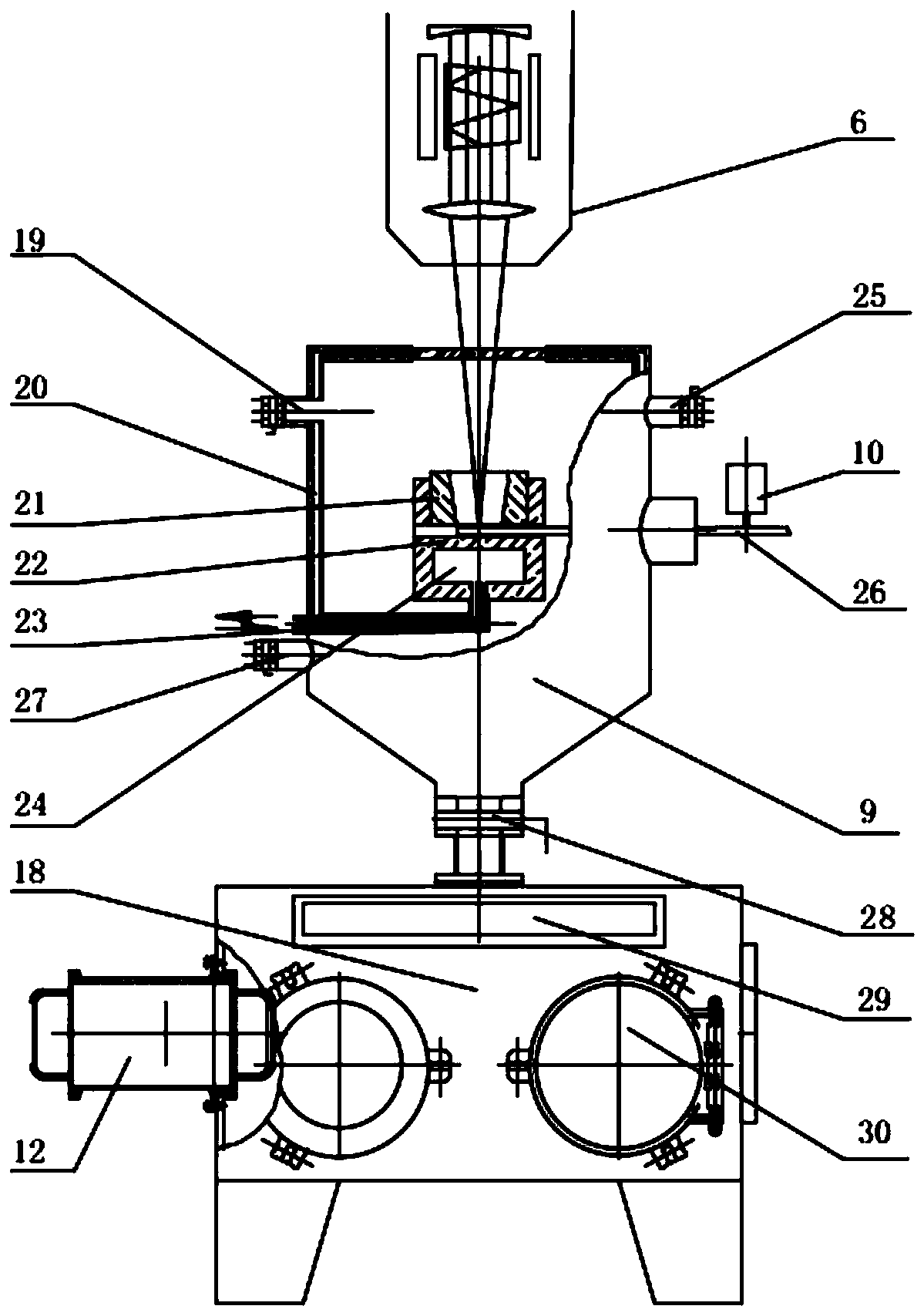

[0038] Such as Figure 1-2 As shown, the laser evaporation multi-cavity nano-powder preparation device is provided with at least two main chamber powder generation units; each main chamber powder generation unit is connected to the vacuum main pipeline 13 through respective vacuum branch pipelines 14, and the vacuum main chamber The pipeline is connected to the vacuum pump group system 17; each main chamber powder generating unit is connected to the main exhaust pipe 2 through respective exhaust branch pipes 4, and each main chamber powder generating unit is respectively connected to Intake main pipeline 3; each main chamber powder generating unit is connected to the control system 1 through their respective feeding control signal lines; the main chamber powder generating unit includes a main chamber 9, a laser device 6, and the main chamber The top of the chamber is provided with a laser device, and the bottom of the main chamber is provided with a collection chamber 18; the ...

Embodiment 2

[0046] Utilize the device described in embodiment 1 to realize the continuous production method of laser evaporation multi-cavity metal nanopowder, comprising the following steps:

[0047] (1) Place the target: install a single metal or metal alloy target with the same composition or different composition on the target holder of each independent cavity as the anode, and use a metal with a melting point higher than 3000°C as the cathode. Gallium arsenide glass with a thickness of 3-5mm is sealed and installed at the opening on the inner wall of the upper cavity, and the gallium arsenide glass is cooled;

[0048] (2) Vacuuming: Close the hatches of each independent cavity, open the vacuum valves of each independent cavity, and use a mechanical pump to vacuumize all the cavities for no more than 10 -1 Pa, and then use the molecular pump to vacuum not higher than 10 -4 Pa, close the vacuum valves of each independent cavity;

[0049] (3) Filling with working gas: open the intake ...

Embodiment 3

[0057] Using the device described in Example 1 to realize the steps of the continuous production method of laser evaporation multi-cavity carbon nanopowder is the same as in Example 1, the difference is:

[0058] In the step (1), the anode target material is a mixture of different types of carbon and a catalyst, the carbon material is graphite, carbon black or activated carbon, the catalyst is a transition metal or yttrium oxide, and when the catalyst is a transition metal, the carbon nanotube obtained is Multi-walled carbon nanotubes, when the catalyst is yttrium oxide, the obtained carbon nanotubes are single-walled carbon nanotubes, and the atomic ratio of carbon atoms to metal atoms in the carbon material and catalyst mixture is 80-100;

[0059] The specific steps of carbon nano powder collection in the step (7) are in-situ carbon nano powder collection: after the consumption of any one of the anode targets is completed, close the arc in the cavity, fill the cavity with arg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com