A kind of heat insulation polyester film for window film and preparation method thereof

A technology of polyester film and window film, applied in the field of polyester film, can solve the problems of increased production energy consumption, complicated preparation process, long drying time, etc., and achieve the effects of avoiding VOC, simple production process and reducing preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

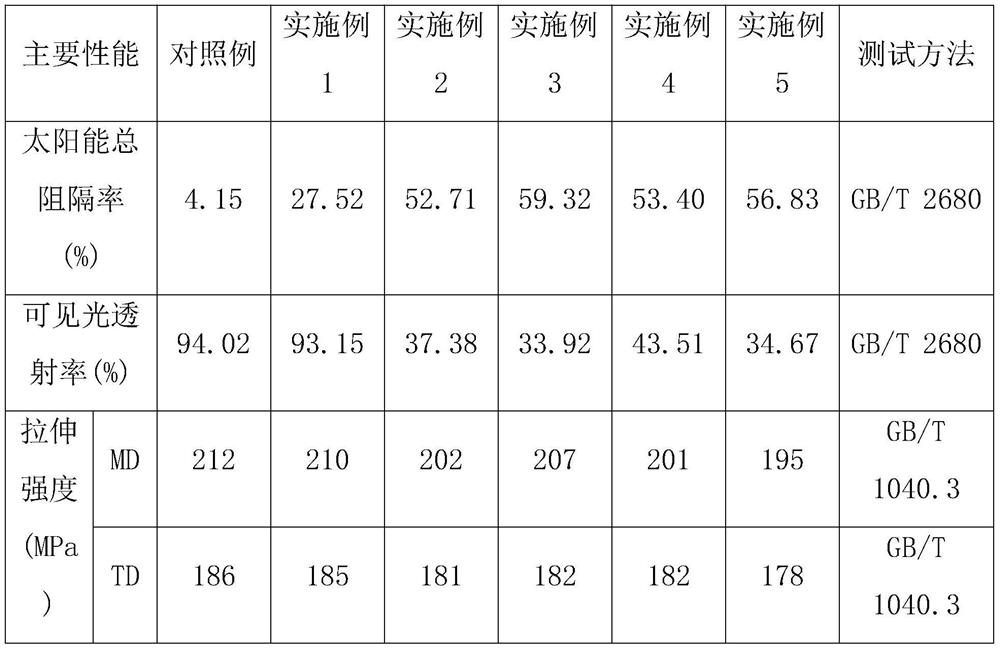

Embodiment 1

[0025] Raw material ratio:

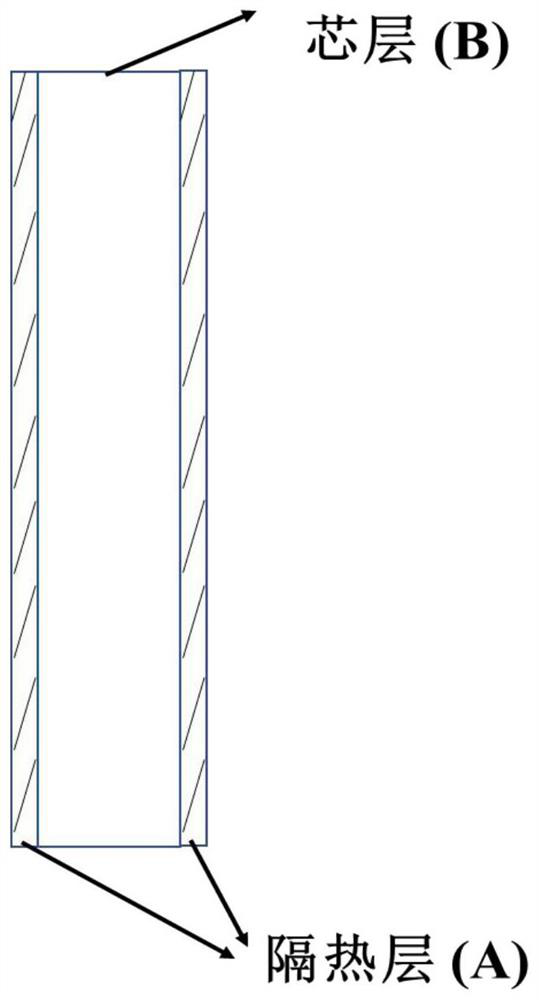

[0026] The core material is 100% optical grade PET chip; the heat insulation layer material is 30% infrared absorption masterbatch and 70% optical grade PET chip, of which the infrared absorption masterbatch is In 2 o 3 and SnO 2 Compounds formed with PET;

[0027] According to the following production process for production:

[0028] 1) Send the raw materials of the core layer and heat insulation layer to the corresponding hopper through the suction system, and control the mass ratio of the extruded melt of the main extruder and the auxiliary extruder to 65:35 through the metering pump. Melt at 270-285°C in the extrusion and auxiliary extruder, vacuumize, and then filter through a filter with a precision of 15um to remove moisture, oligomers and impurities in the raw material melt and use it as the melt of the main extrusion and auxiliary extrusion ; The obtained main extrusion melt and auxiliary extrusion melt are merged and extruded in an AB...

Embodiment 2

[0034] Raw material ratio:

[0035] The core material is 15% black color masterbatch and 85% optical grade PET chip; the heat insulation layer material is 30% infrared absorbing masterbatch and 70% optical grade PET chip, of which the infrared absorbing masterbatch is In 2 o 3 and SnO 2 Compounds formed with PET;

[0036] According to the following production process for production:

[0037] 1) Send the raw materials of the core layer and heat insulation layer to the corresponding hopper through the suction system, and control the mass ratio of the extruded melt of the main extruder and the auxiliary extruder to 65:35 through the metering pump. Melt at 270-285°C in the extrusion and auxiliary extruder, vacuumize, and then filter through a filter with a precision of 15um to remove moisture, oligomers and impurities in the raw material melt and use it as the melt of the main extrusion and auxiliary extrusion ; The obtained main extrusion melt and auxiliary extrusion melt are...

Embodiment 3

[0043] Raw material ratio:

[0044] The core material is 15% black color masterbatch and 85% optical grade PET chip; the heat insulation layer material is 26% infrared absorbing masterbatch and 74% optical grade PET chip, of which the infrared absorbing masterbatch is In 2 o 3 , SnO 2 and Sb 2 o 3 Compounds formed with PET;

[0045] According to the following production process for production:

[0046] 1) Send the raw materials of the core layer and heat insulation layer to the corresponding silo through the suction system, and control the mass ratio of the extruded melt of the main extruder and the auxiliary extruder to 70:30 through the metering pump. Melt at 270-285°C in the extrusion and auxiliary extruder, vacuumize, and then filter through a filter with a precision of 15um to remove moisture, oligomers and impurities in the raw material melt and use it as the melt of the main extrusion and auxiliary extrusion ; The obtained main extrusion melt and auxiliary extrusi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com