Pickling method of stainless steel covered by acid-proof cloth

A technology of stainless steel and pickling method, which is applied in the field of metal pickling and surface treatment, which can solve the problems of slow pickling speed, high cost, and environmental pollution, and achieve the goals of avoiding environmental pollution, fast pickling speed, and low pickling cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

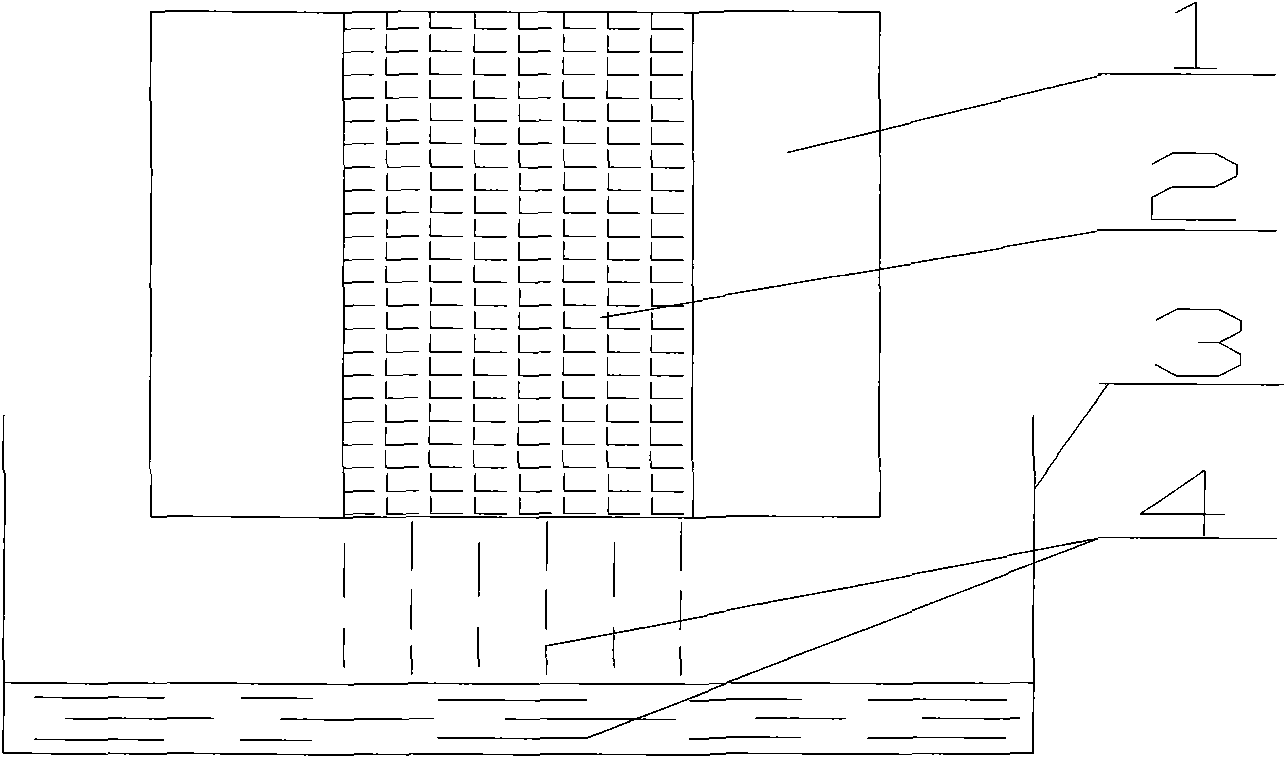

[0020] Such as figure 1 As shown, put the stainless steel cladding of the composite plate facing upwards, and place it obliquely on the upper end of the solution recovery tank. On the surface of stainless steel that needs to be pickled, cover it with 3 layers of acid-resistant cloth, and spray pickling solution on the surface of the acid-resistant cloth every 5 to 10 minutes to keep the acid-resistant cloth moist. Excess pickling liquid flows into recovery tank. Roll the acid-resistant cloth with a plastic roller to drive away the air bubbles under the cloth. Pickling treatment. When the temperature is low, heat the pickling solution to 20-30°C in the acid storage tank, and spray the pickling solution on the surface of the acid-resistant cloth every 2-3 minutes to maintain the pickling temperature and concentration. If necessary, heat the acid-resistant cloth with hot air to maintain the pickling temperature. In hot weather, uncover the acid-resistant cloth on the thinner ...

Embodiment approach 2

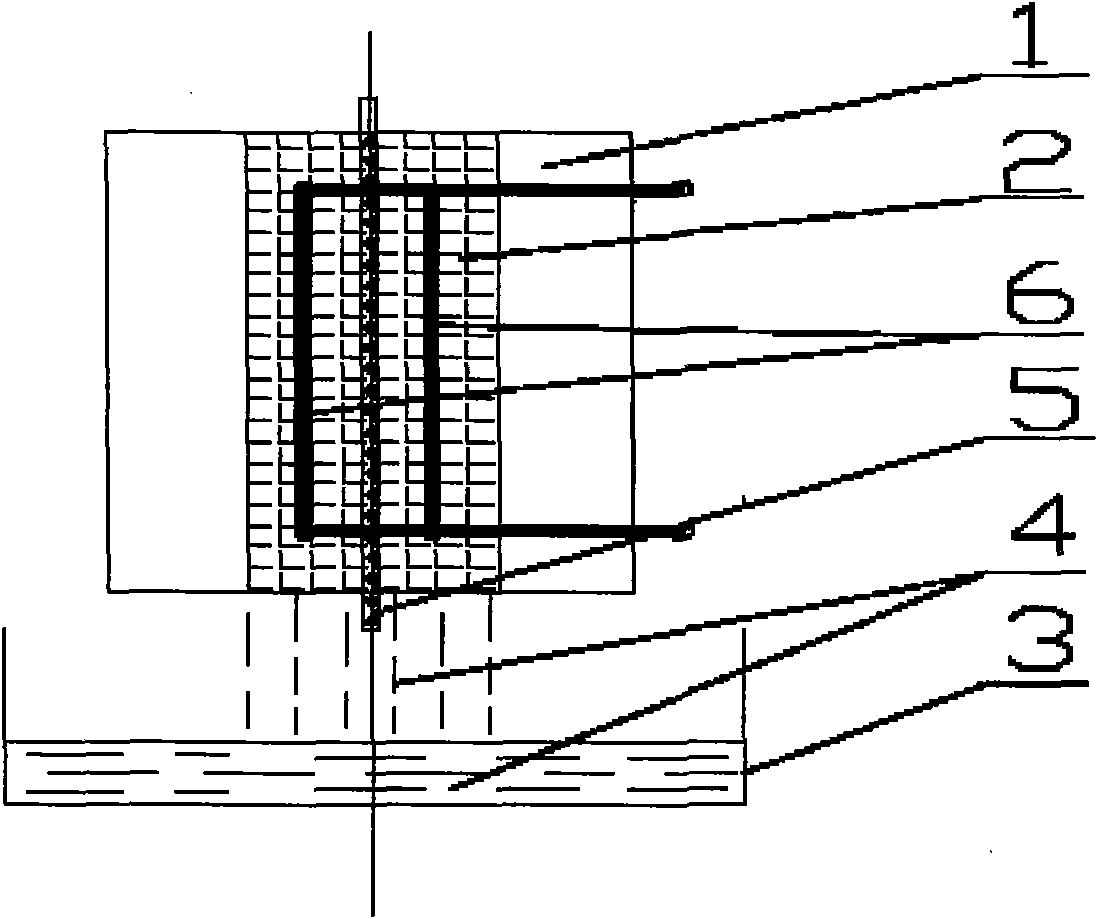

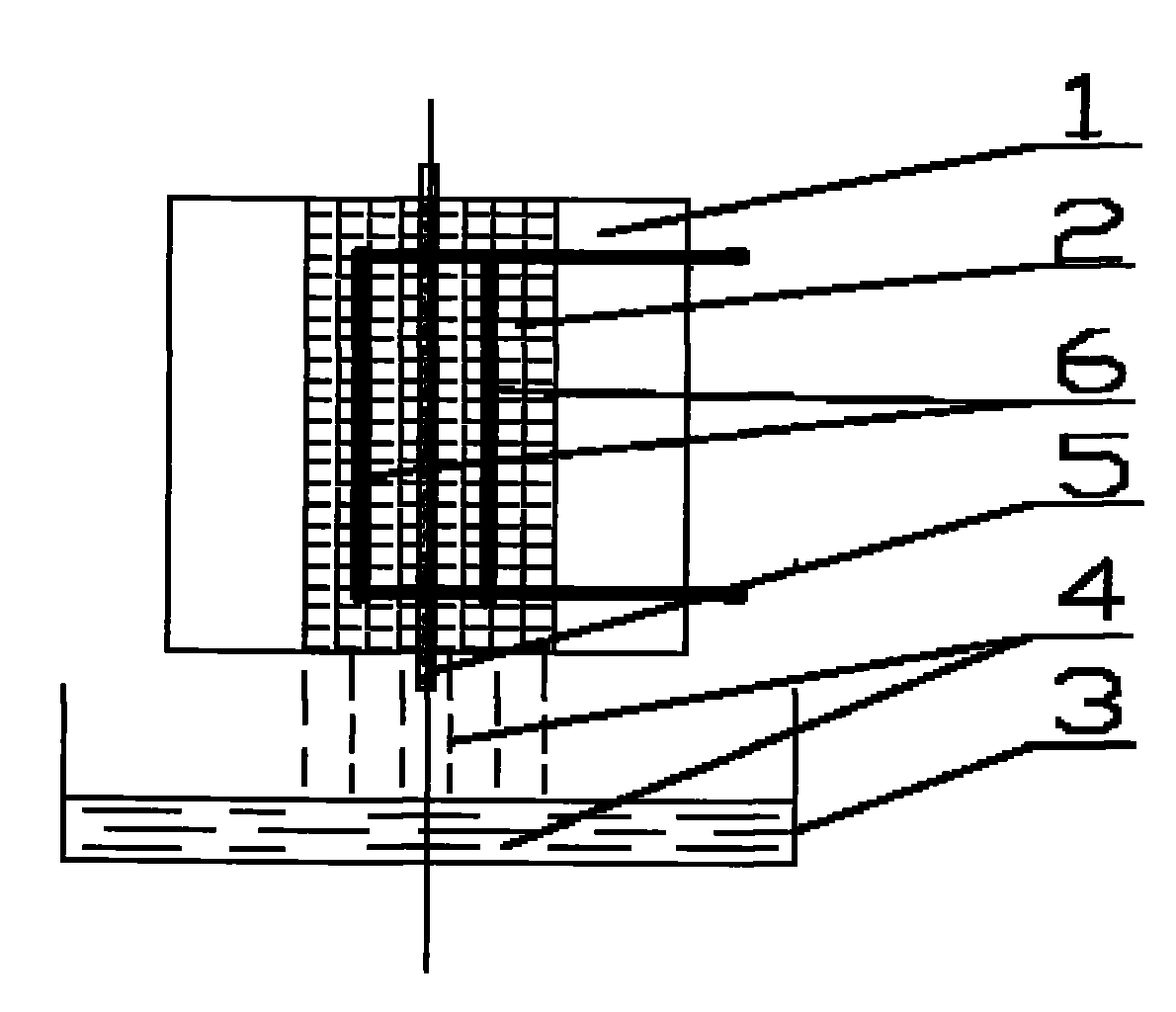

[0022] Such as figure 2 As shown, put the stainless steel cladding of the composite plate facing upwards, and place it obliquely on the upper end of the solution recovery tank. On the surface of the stainless steel that needs to be pickled, cover 4 layers of acid-resistant cloth, and between the two layers of cloth, put porous plastic pipes and electric heaters in appropriate positions. Acid cleaning solution is supplied to acid-resistant cloth through acid-resistant pump and porous plastic pipe. When the temperature is low, heat the pickling solution to 20-30°C in the acid storage tank, and heat the pickling cloth with an electric heater. Control the concentration and temperature of the pickling solution within the optimum process range, uncover the pickling cloth at any time to check the pickling situation, and finally the pickling cloth and pickling solution are cleaned, filtered, etc., stored, and used many times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com