Photomask, thin film transistor element and manufacturing method of thin film transistor element

A thin-film transistor and photomask technology, applied in transistors, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of decreased aperture ratio, difficulty, increased resistance and capacitance load, etc., and achieve the effect of high turn-on current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to further understand the present invention, several preferred embodiments of the present invention are listed below, and together with the accompanying drawings, the composition and desired effects of the present invention are described in detail.

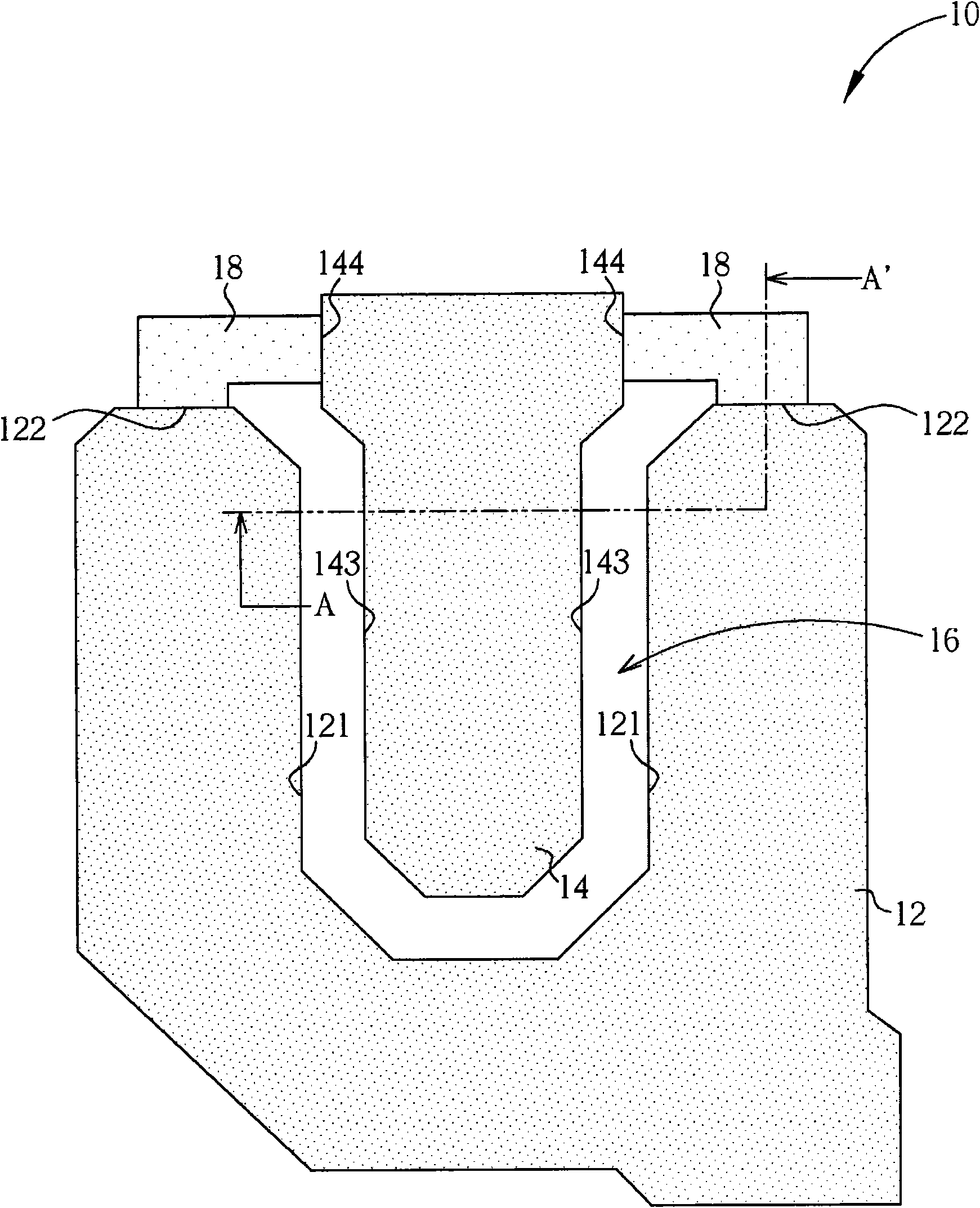

[0028] Please refer to figure 1 . figure 1 A schematic diagram of a photomask according to a preferred embodiment of the present invention is shown. In this embodiment, the photomask 10 may be a grayscale photomask (GTM), a halftone mask (HTM), or other photomasks with different light transmittances in different regions . The photomask 10 of this embodiment includes a first light-shielding pattern 12 , a second light-shielding pattern 14 , a light-transmitting single slit 16 and a semi-light-transmitting pattern 18 . The first shading pattern 12 includes a first side 121 and a second side 122 , the second shading pattern 14 includes a third side 143 and a fourth side 144 , and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com