Novel metalizing polypropylene thin film capacitor

A polypropylene film and polypropylene film technology, used in the field of capacitors, can solve the problems of small effective facing area of the pole plate, small contact surface of the gold spray layer, large capacitor volume, etc., and achieves small square resistance, stable loss value, and increased The effect of facing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

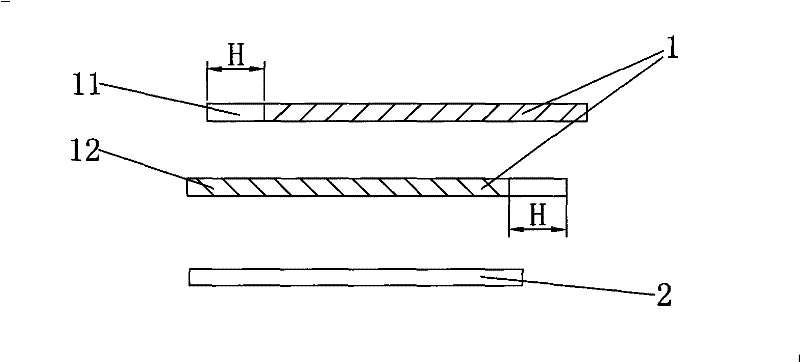

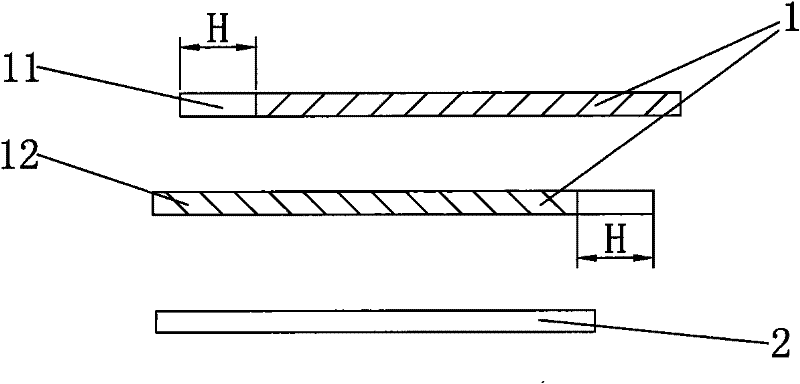

[0014] Such as figure 2 The schematic diagram of the winding section structure of the metallized polypropylene film capacitor of the present invention is shown, and the capacitor is provided with two layers of evaporated polypropylene film 1 with a single side left side stacked on each other, and a layer of polypropylene film 2 is superimposed on one layer of single side leftover On the non-superimposed surface of the edge-evaporated polypropylene film 1, the two inner surfaces that are in contact with each other between the two layers of single-layer evaporated polypropylene film 1 are the superimposed surface, so the above-mentioned non-superposed surface refers to the surface with the single The outer side corresponding to the superimposed side of the polypropylene film 1 is left to be vapor-deposited. The thickness of the film layer increases the pressure resistance, and at the same time the side area increases, the contact surface of the gold spray layer increases, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com