Method for producing potash magnesium sulphate fertilizer

A technology for potassium-magnesium sulfate fertilizer and potassium feldspar, which is applied in the directions of magnesium fertilizer, potash fertilizer, inorganic fertilizer, etc., can solve the problems of high transportation cost, low utilization value, restricting the normal and continuous production of salt lake potassium fertilizer, etc., and achieves a simple separation process, The effect of low roasting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

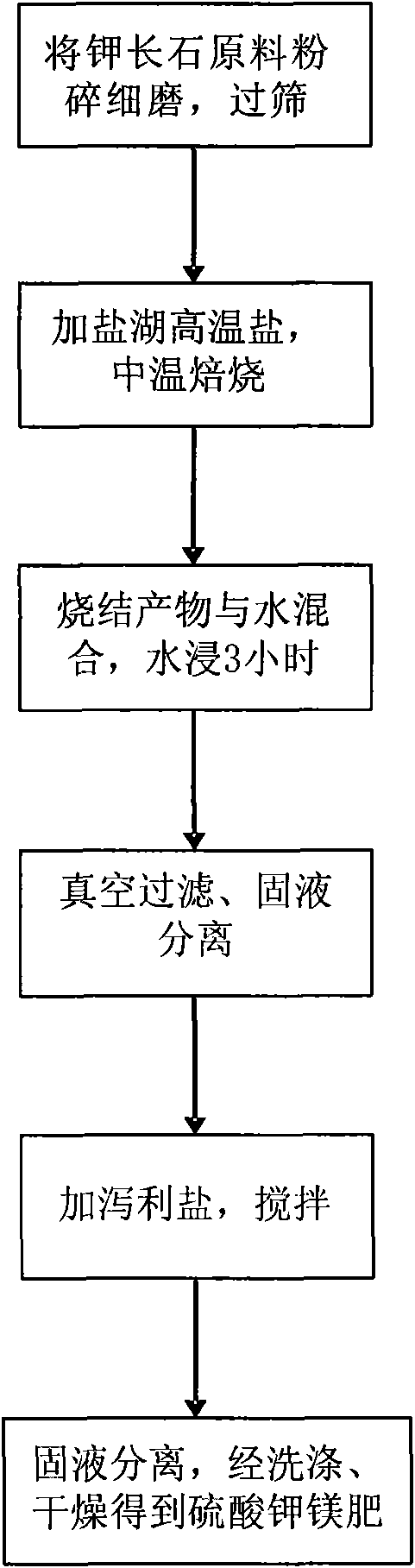

Image

Examples

Embodiment Construction

[0030] Such as figure 1 , pass 500g through 150 mesh containing K 2 O 9.78%, Al 2 o 3 16.95%, SiO 2 69.41%, Na 2 O1.24% potassium feldspar ore powder and 600g salt lake hydrous schlorite solid waste (MgCl 2 ·6H 2 (about 80% purity) and mix well, put into an iron crucible and add a cover (sealed iron crucible) to roast for 2 hours (placed in a muffle furnace with a heating rate of 10°C / min and kept at 600°C for 2 hours).

[0031] The sintered product is crisp and crisp in texture, ground and sieved (100 mesh Taylor sieve), mixed with 5 kg of tap water, stirred and reacted at 60° C. for 3 hours,

[0032] Vacuum filtration for solid-liquid separation, the filter cake was washed with 0.2kg tap water, the potassium leaching recovery rate was 86% to 90%, and the mixed material liquid contained K + 8.55g / L, SiO 2 0.52g / L, Al 2 o 3 0.29g / L, Na + 0.71g / L, Mg 2+ 10.06g / L, Cl - 35.82g / L, add the solid waste (containing MgSO 4 ·6H 2 O 74.6%, K 2 SO 4 15.2%, water 8.8%) an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com