N, N, N', N'-tetraallylethylene diamine and preparation method thereof

A technology of tetraallyl ethylenediamine and ethylenediamine, which is applied in the N field, can solve the problems of quaternary ammonium salt polymers that have not been disclosed in literature, and achieve the effects of improving utilization rate, increasing yield, and reducing the discharge of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

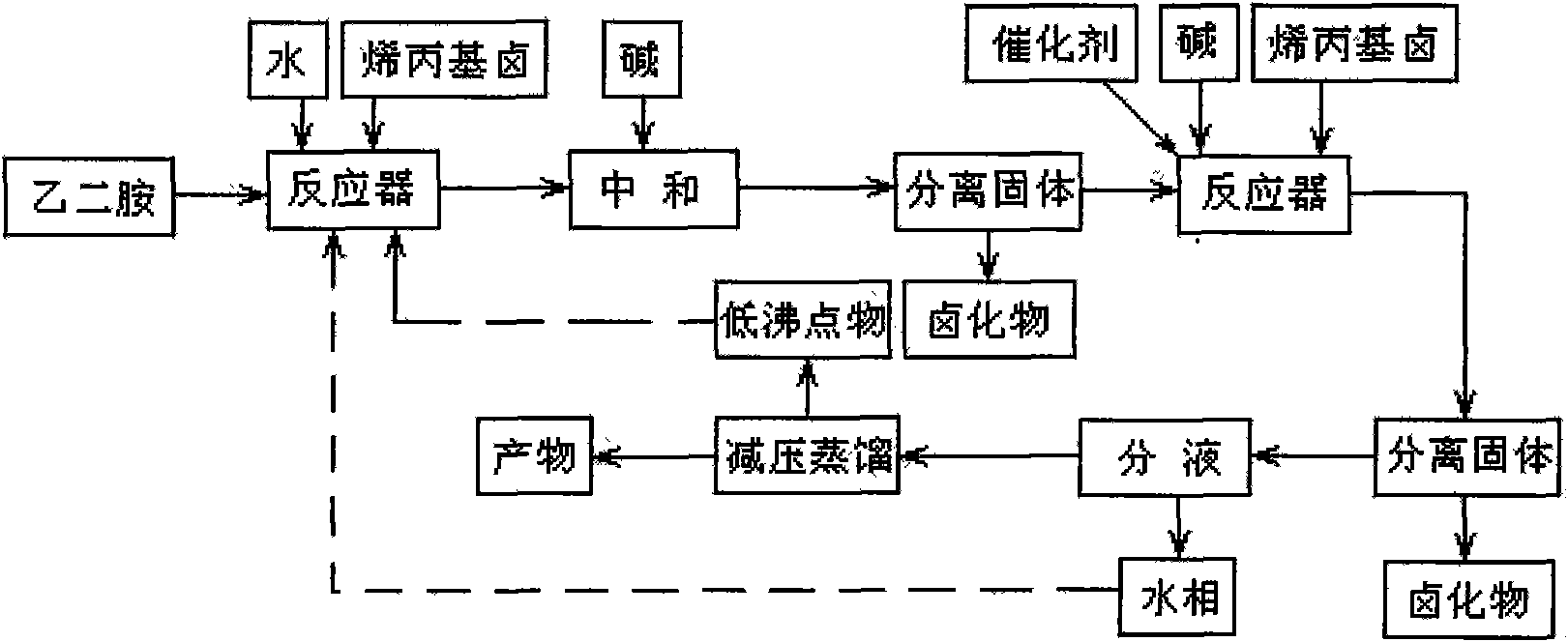

Method used

Image

Examples

Embodiment 1

[0044] (1) According to the molar ratio of ethylenediamine, allyl chloride and alkali as 1:2.1:2.1, first add 100mL of ethylenediamine into a 1L stainless steel reaction kettle with a mechanical stirrer, add 90mL of water to make a mass Add 262 mL of allyl chloride to a 50% aqueous solution, seal the reaction vessel, and react at 50°C for 5 hours; then add 185.1 mL of 45% NaOH solution while stirring to neutralize, and cool to room temperature , crystallize out, separate the solid, and return the liquid phase to the reactor;

[0045] (2) Add 50% of the alkali used in step (1), i.e. 61.5g NaOH, to the above liquid phase, stir and dissolve, then add 262mL of allyl chloride and 4.5g of phase transfer catalyst PEG-400 in the same amount used in step (1) 1. Close the reactor, react at 60 DEG C for 5 hours, then add 50% of the alkali used in step (1), i.e. 61.5 g NaOH, continue the reaction for 5 hours in the closed reactor, cool to room temperature, precipitate crystals, and separa...

Embodiment 2

[0056] (1) The aqueous phase and the low-boiling fraction collected in step (5) in Example 1 are added to the reactor and then participate in this round of reaction;

[0057] (2) According to the molar ratio of ethylenediamine, allyl chloride and alkali as 1:2.1:2.1, add 100mL of ethylenediamine and 262mL of allyl chloride into the reaction kettle respectively, seal the reaction kettle, and react at 50°C 5h; then add 185.1mL NaOH solution with a concentration of 45% by mass to neutralize while stirring, cool to room temperature, precipitate crystals, separate solids, and return the liquid phase to the reactor;

[0058] (3) Add 50% of the alkali used in step (2), i.e. 61.5g NaOH, to the above liquid phase, stir and dissolve, then add 262mL of allyl chloride and 4.5g phase transfer catalyst PEG-400 in the same amount used in step (2) 1. Close the reactor, react at 60 DEG C for 5 hours, then add 50% of the alkali used in step (2), i.e. 61.5 g NaOH, continue the reaction for 5 hou...

Embodiment 3

[0064] (1) The aqueous phase and the low boiling point fraction that step (6) collects among the embodiment 2 is added in the reactor and participates in this round of reaction again;

[0065] (2) According to the molar ratio of ethylenediamine, allyl chloride and alkali as 1:2.0:2.0, add 100mL of ethylenediamine and 249mL of allyl chloride into the reaction kettle respectively, seal the reaction kettle, and react at 40°C 6h; then add 176.5mL NaOH solution with a concentration of 45% by mass to neutralize while stirring, cool to room temperature, precipitate crystals, separate solids, and return the liquid phase to the reactor;

[0066] (3) Add step (2) 50% alkali of the amount used in the above-mentioned liquid phase, i.e. 59gNaOH, fully stir and dissolve and then add the same allyl chloride 249mL and 2.3g phase transfer catalyst PEG-400 of the amount used in step (2), Close the reactor, react at 60°C for 6 hours, then add 50% of the alkali used in step (2), i.e. 59g NaOH, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com