Intelligent response control electrical desalting and dewatering electric field device

A technology of electric desalination dehydration and electric field, which is applied in the fields of electric/magnetic dehydration/demulsification, electric liquid separation, liquid separation auxiliary equipment, etc. and other problems to achieve the effect of improving the desalination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

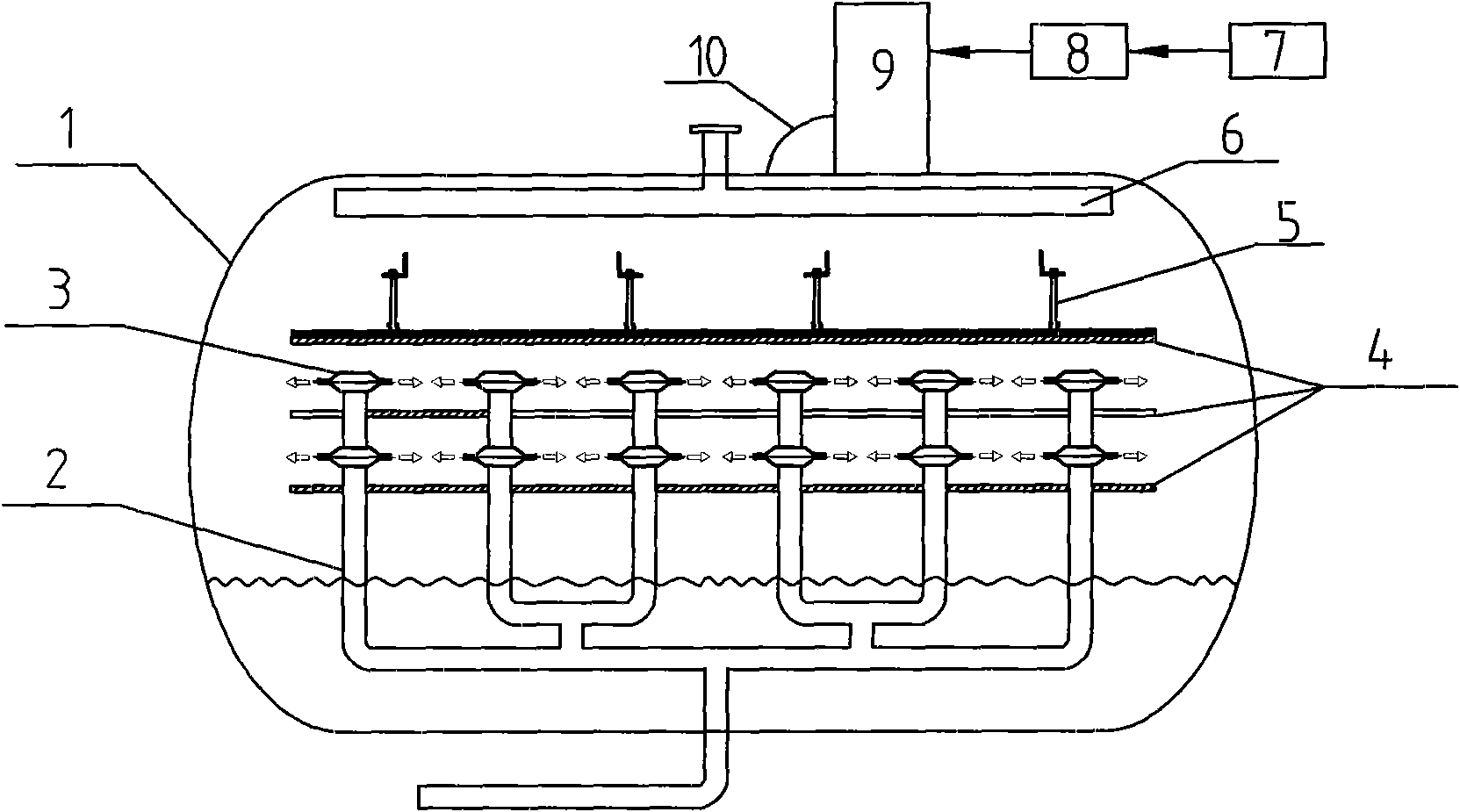

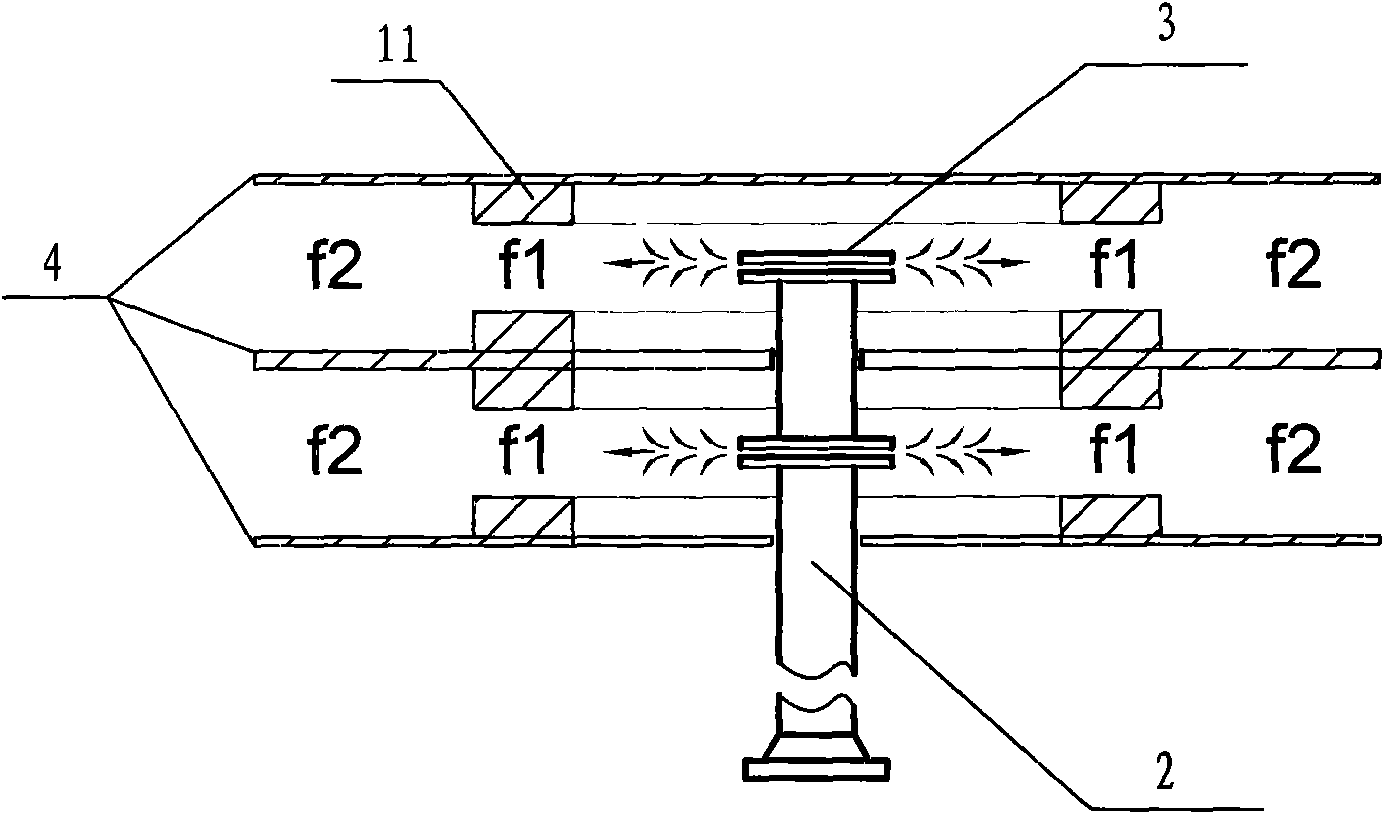

[0020] The intelligent response control electric desalination and dehydration electric field device of this embodiment is such as figure 1 with figure 2 As shown, the electric desalination and dehydration tank body 1 is provided with an oil inlet distributor 2 and a three-layer horizontal high-voltage electrode plate 4, wherein the uppermost high-voltage electrode plate is suspended in the tank body by an insulating suspension 5. Since the PLC controller is connected to the transformer through the voltage regulator, and the voltage device is connected to the high voltage electrode plate through the high voltage electrode rod, the voltage of the high voltage electrode plate 4 is derived from the voltage regulator 8 controlled by the PLC controller 7 through the high voltage electrode of the transformer 9 The voltage output by the rod 10. The oil inlet distributor 2 is composed of separated branch pipelines and has a tree-like structure. Each branch pipeline is equipped with an oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com