Microbiological cell device and municipal sludge disposal method

A technology for microbial batteries and municipal sludge, which is applied in sludge treatment, biochemical fuel cells, water/sludge/sewage treatment, etc., can solve the problems of unfavorable operation mode, high sludge cost, structural defects, etc., and achieve COD removal. Good effect, easy to expand and enlarge, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

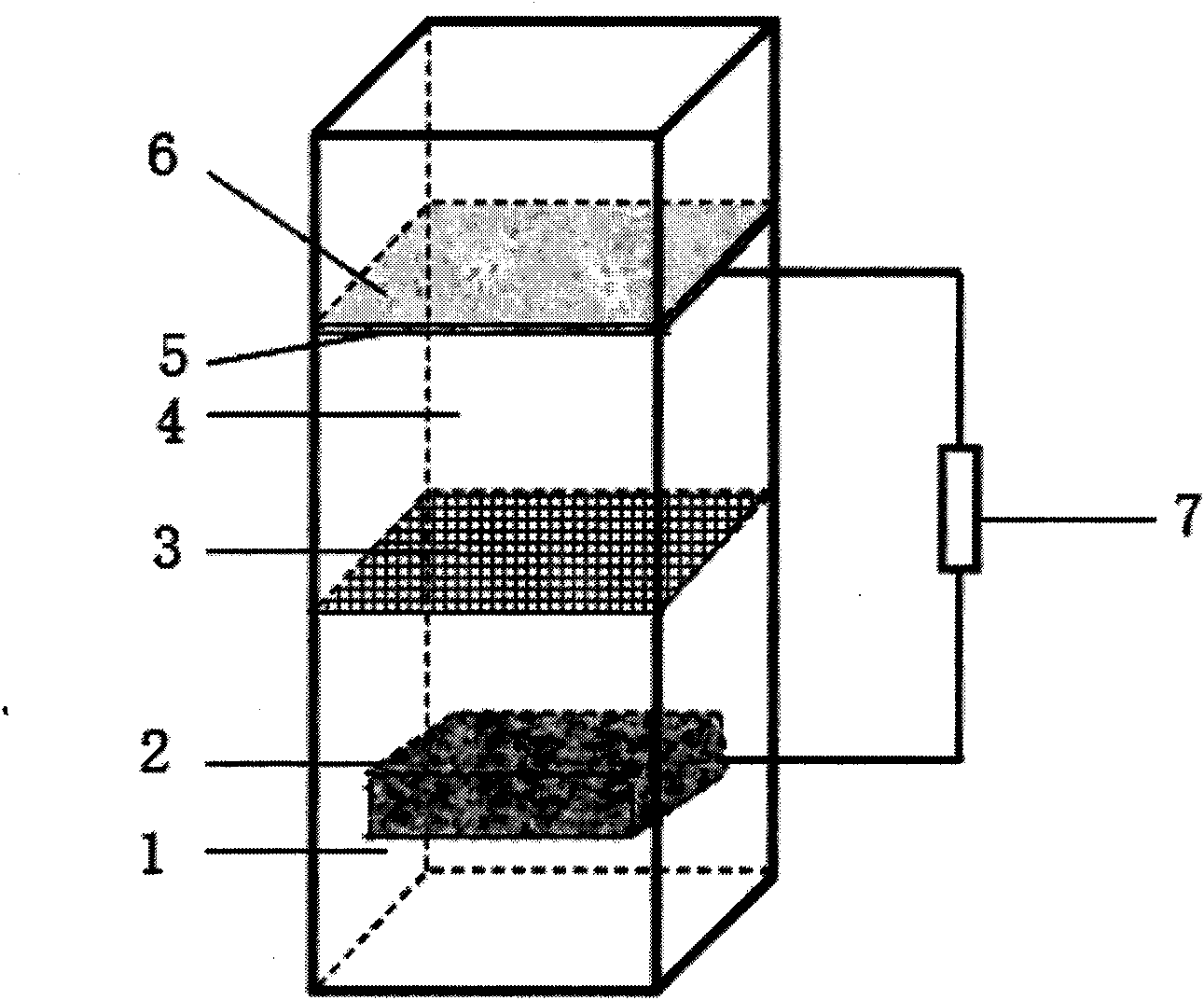

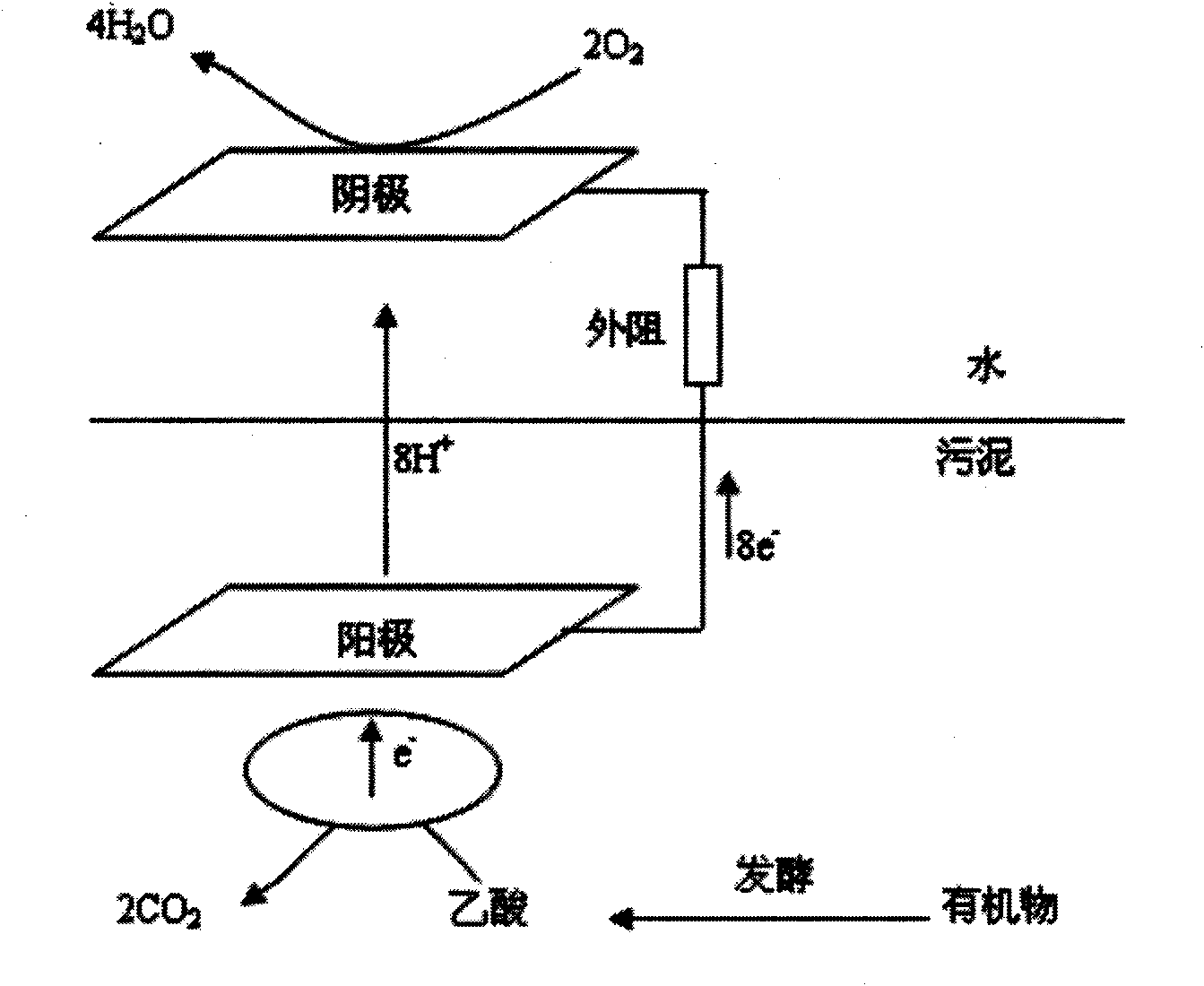

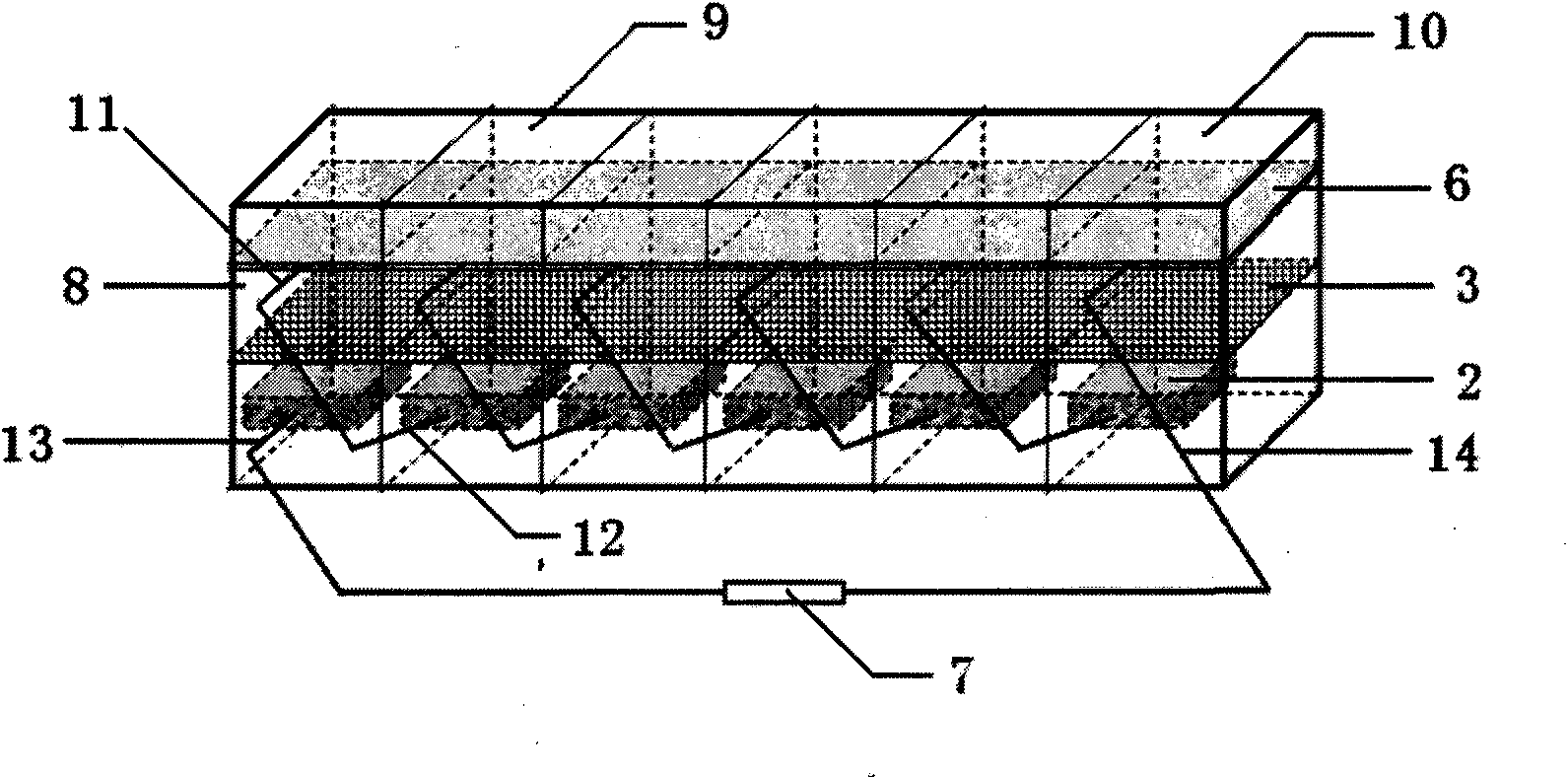

[0040] Example 1 Disposal of Municipal Sludge Using Microbial Fuel Cells

[0041] The invention provides a kind of disposal method of municipal sludge, comprising the following steps:

[0042] (1) Set an open container, install the anode of the microbial fuel cell at the bottom of the container; place the municipal sludge in the microbial fuel cell container for natural settlement to produce a supernatant, and set an isolation material to isolate the sludge from the supernatant ;

[0043] The cathode of the microbial fuel cell is installed on the supernatant, one side of the cathode is in contact with the surface of the supernatant, and the catalyst-coated side of the cathode is in contact with the air;

[0044] (2) Connect the anode and cathode of the microbial fuel cell with wires, connect the external circuit, and carry out the domestication of the electricity-producing microorganisms; after the anode microorganisms are domesticated, repeat the sludge disposal and electric...

Embodiment 2

[0055] Example 2 Sludge Microbial Fuel Cell Single Sludge Treatment and Electricity Production Effect Experiment

[0056] (1) Municipal sludge samples

[0057] The sludge used for the test was concentrated sludge from Beijing Gaobeidian Sewage Treatment Plant, which was recovered and stored in a refrigerator at 4°C. The physical and chemical properties of sludge are as follows: pH is 6.86; volatile organic matter content is about 49.5%; total carbon, 279.4 g / kg; total nitrogen, 27.6 g / kg.

[0058] (2) Construction of microbial fuel cells

[0059] as attached figure 1 As shown, a cuboid container of polyethylene material with a side length of 6 cm in cross section is adopted, and the total height of the container is 10 cm. Inject 144mL of sludge into the feed port below the container (conventional technology, not marked in the figure). The height of the sludge surface from the bottom of the battery is about 4cm, and a carbon felt with a projected area of 25cm (5×5cm) is us...

Embodiment 3

[0063] Example 3 Sludge Microbial Fuel Cell Single Sludge Treatment and Electricity Production Effect Experiment

[0064] (1) Sludge sample

[0065] The sludge used in the test was concentrated sludge from Guangzhou Liede Wastewater Treatment Plant, which was recovered and stored in a refrigerator at 4°C. The physical and chemical properties are as follows: pH is 6.69; volatile organic matter content is 45.2%; total carbon is 232.3 g / kg; total nitrogen is 28.2 g / kg. The moisture content of the tested sludge was 96.7%, and the COD was 29050mg / L.

[0066] (2) Construction of the battery

[0067] A polyethylene cuboid container with a side length of 6 cm is adopted, and the total height of the container is 10 cm. Inject 144mL of sludge from the inlet below. The height of the sludge surface from the bottom of the battery is 4cm, and the carbon felt with a projected area of 25cm (5×5cm) is used as the anode. It is placed in the sludge 2cm below the sludge surface and filled wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com