Composite oxide catalyst for producing hydrogen by reforming methanol steam, preparation and application thereof

A composite oxide, steam reforming technology, applied in metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, physical/chemical process catalyst, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

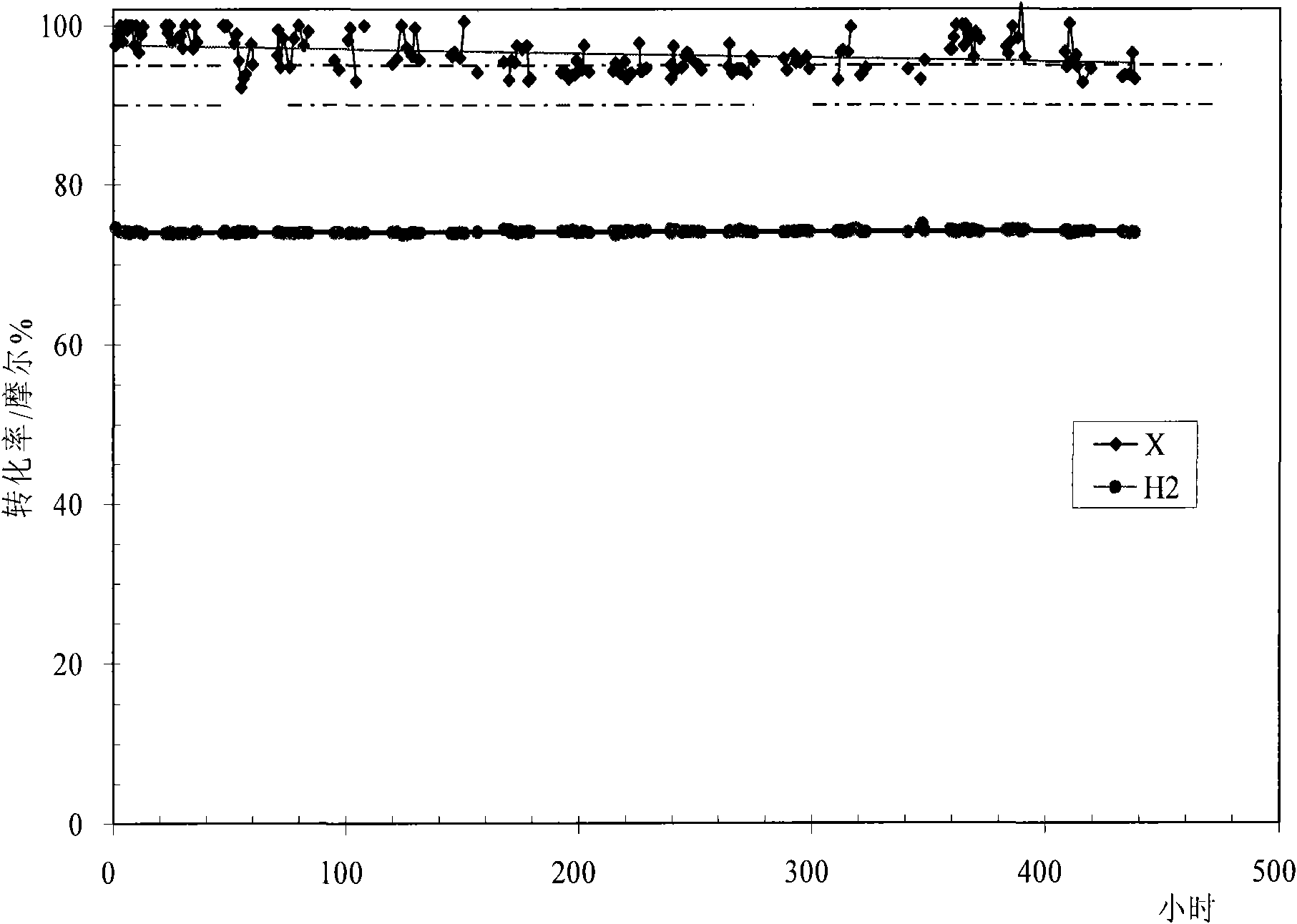

Image

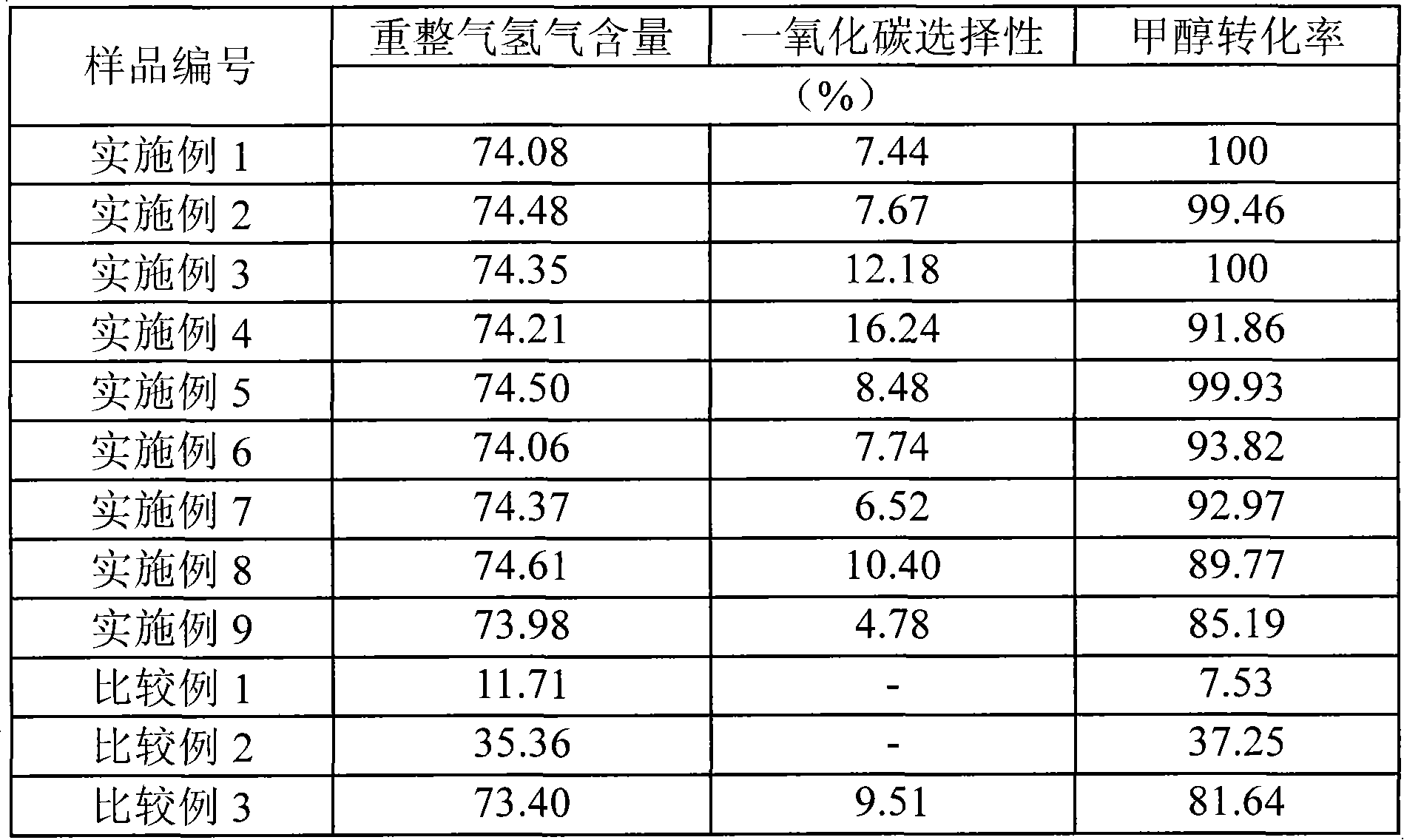

Examples

Embodiment 1

[0019] Weigh Ce(NO 3 ) 3 ·6H 2 45.5g of O was thermally decomposed in a muffle furnace at 450°C for 4 hours to obtain CeO 2 Powder for later use. Weigh 6.97g Zr(NO 3 ) 4 ·5H 2 O is added with water to form an aqueous solution with a concentration of 0.2 g / ml, and an equal volume of CeO is impregnated. 2 , satisfying ZrO 2 The content is 10wt%, and it is ready for use after being dried and calcined at 500°C.

[0020] Weigh Cr(NO 3 ) 3 9H 2 O 3.95g, Zn(NO 3 ) 2 ·6H 2 O 12.79g was dissolved in deionized water, and diluted to 150ml, then mixed with 3g ZrO 2 -CeO 2 Mix the dry powder evenly, titrate with 1mol / L ammonia water to pH=7 under stirring, filter and wash, dry at 110°C, and bake at 500°C for 3 hours.

Embodiment 2

[0022] Weigh Cr(NO 3 ) 3 9H 2 O 3.95g, Zn(NO 3 ) 2 ·6H 2 O 9.44g adds deionized water and dissolves and dilutes to 150ml, and the 3g ZrO prepared with example 1 2 -CeO 2 The dry powder is mixed evenly, and the following preparation method is the same as Example 1.

Embodiment 3

[0024] Weigh Cr(NO 3 ) 3 9H 2 O 6.63g, Zn(NO 3 )2 ·6H 2 O 10.74g adds deionized water to dissolve and dilute to 150ml, and the ZrO that 3g example 1 prepares 2 -CeO 2 The dry powder is mixed evenly, and the following preparation method is the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com