Method and system for grinding double sides of disc type rotary work piece, and vertical double-sided grinding machine with numerical control synchronous double-sided grinding head

A technology of rotating workpieces and double-sided grinding machines, which is applied to machine tools, grinding machines, and metal processing equipment suitable for grinding workpiece planes, and can solve the problems of low efficiency of single-sided grinding, complex structure of the processing system, and low processing accuracy. Achieve the effects of small space occupation, saving human resources and improving the quality of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

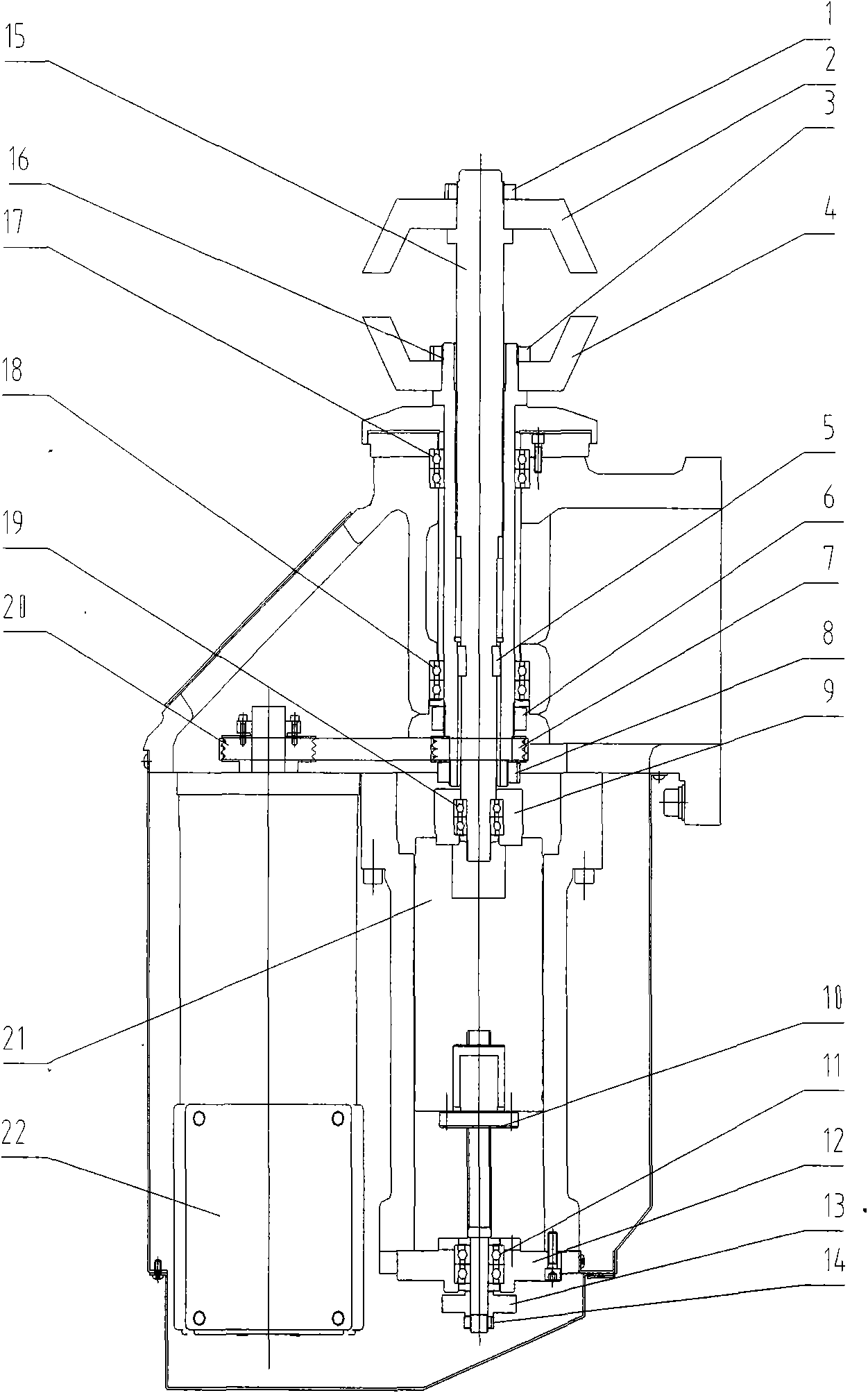

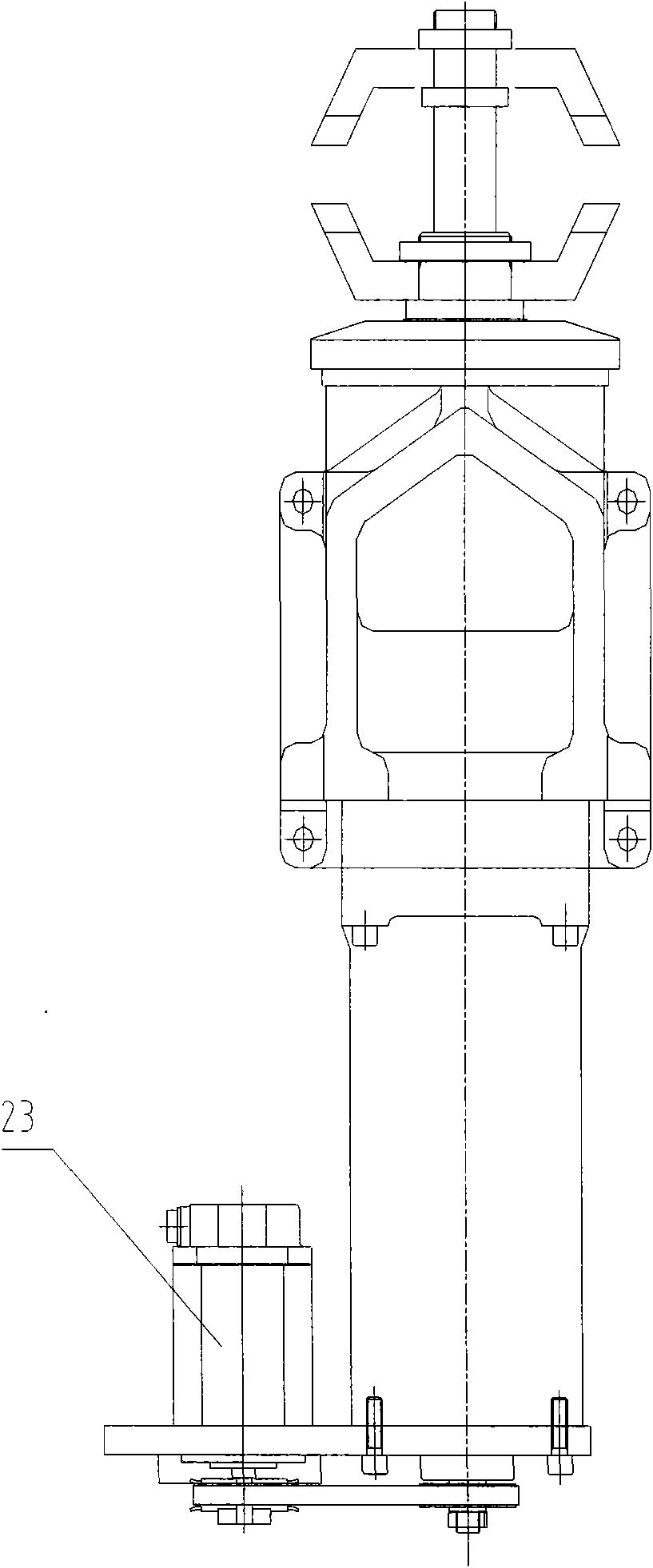

[0018] see figure 1 with figure 2 , the present invention provides a method for double-sided grinding of disc-type rotary workpieces, and also provides a double-sided grinding system using this method and a vertical double-sided grinding head equipped with digitally controlled synchronous double-sided grinding heads for double-sided grinding. The grinding machine has successfully solved the difficulty of synchronous double-sided grinding of high-precision, especially ultra-thin disc-type rotary workpieces, improved the production efficiency of grinding disc-type rotary workpieces, reduced the resources used in production, and stabilized product quality.

[0019] The transmission system used to transfer workpieces such as disc-type rotary workpieces on the production line generally adopts a conveyor belt system. The inverted rotary clamping mechanism for clamping disc-type rotary workpieces and other workpieces is matched with the conveyor belt system, and the workpiece can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com