Polishing grinding head

A polishing grinding and grinding seat technology, which is applied in the field of polishing equipment and grinding, can solve problems such as difficult to realize multi-degree-of-freedom arbitrary swing, high crushing rate, and high noise, and achieve the goals of reducing power, improving mechanical properties, and reducing total weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

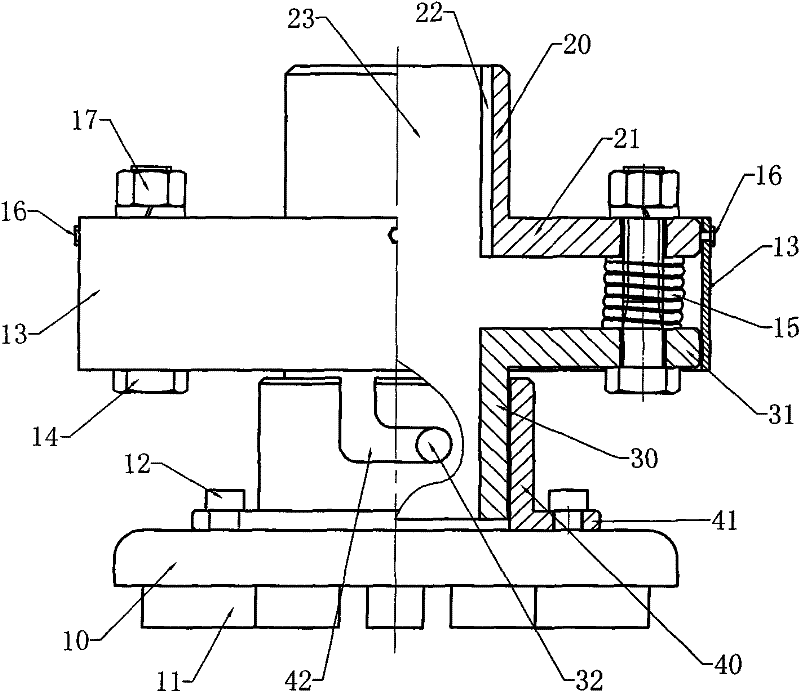

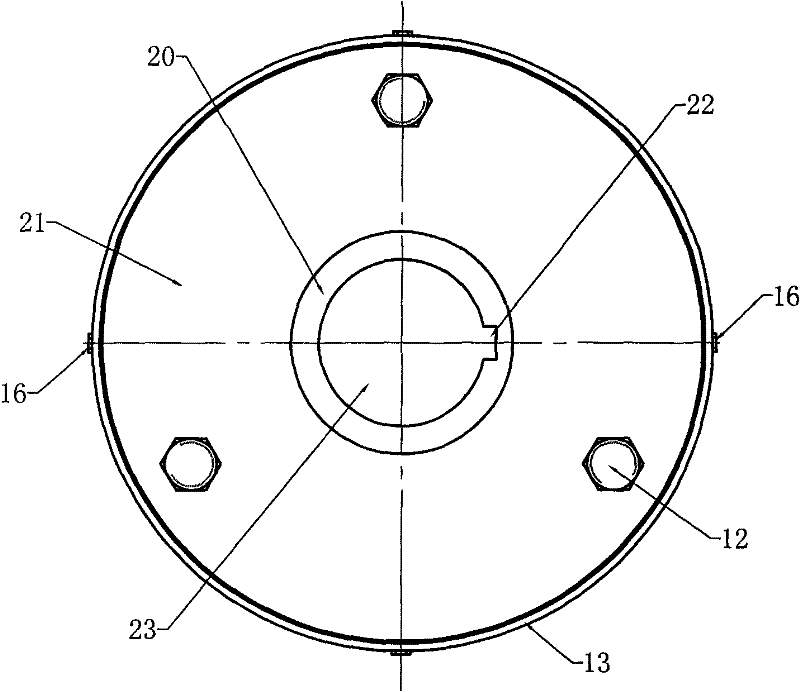

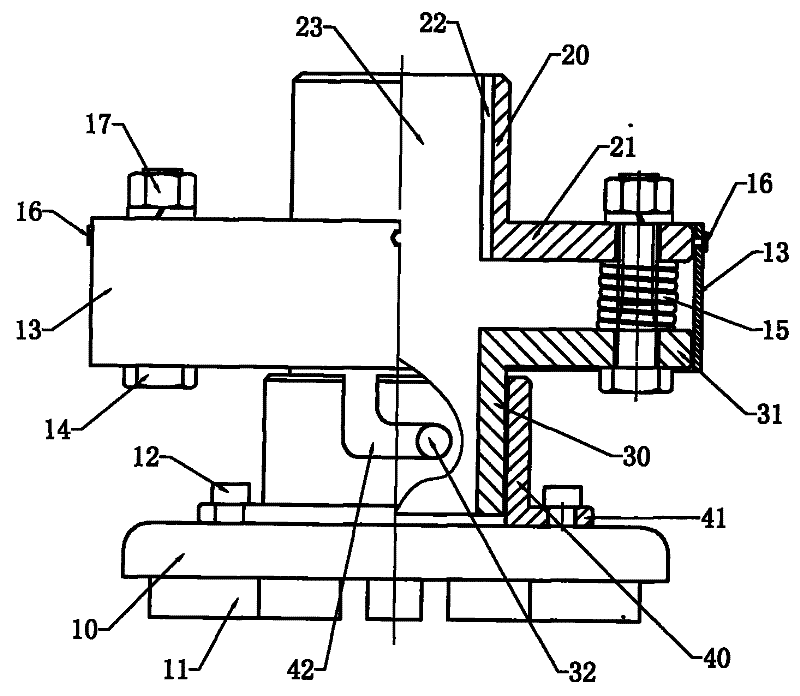

[0020] refer to Figure 1-Figure 2 , a polishing grinding head, comprising a grinding disc 10 and a grinding head installation structure, above the grinding disc 10, a cylindrical lower grinding base 40, a cylindrical middle grinding base 30 and a cylindrical upper grinding base 20 are arranged successively, and the lower grinding base The lower end of the base 40, the upper end of the middle grinding base 30 and the lower end of the upper grinding base 20 are respectively provided with flanges, the grinding disc 10 is connected with the lower grinding base flange 41 by bolts 12, and the cylindrical lower grinding base 40 is overlaid on the on the cylindrical middle grinding base 30 and is connected by a buckle device, and the buckling device is composed of a bayonet pin 32 radially arranged on the cylindrical middle grinding base 30 and a lower grinding base 40 which is matched with the bayonet The "L" shaped card slot 42 constitutes. Between the cylindrical middle grinding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com