Super-active slag powder and production method thereof

A slag powder and super-active technology, which is applied in chemical instruments and methods, climate sustainability, fibrous fillers, etc., can solve the problems that the early strength of concrete has no obvious effect, and achieve novel preparation methods, accelerated reaction speed, The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

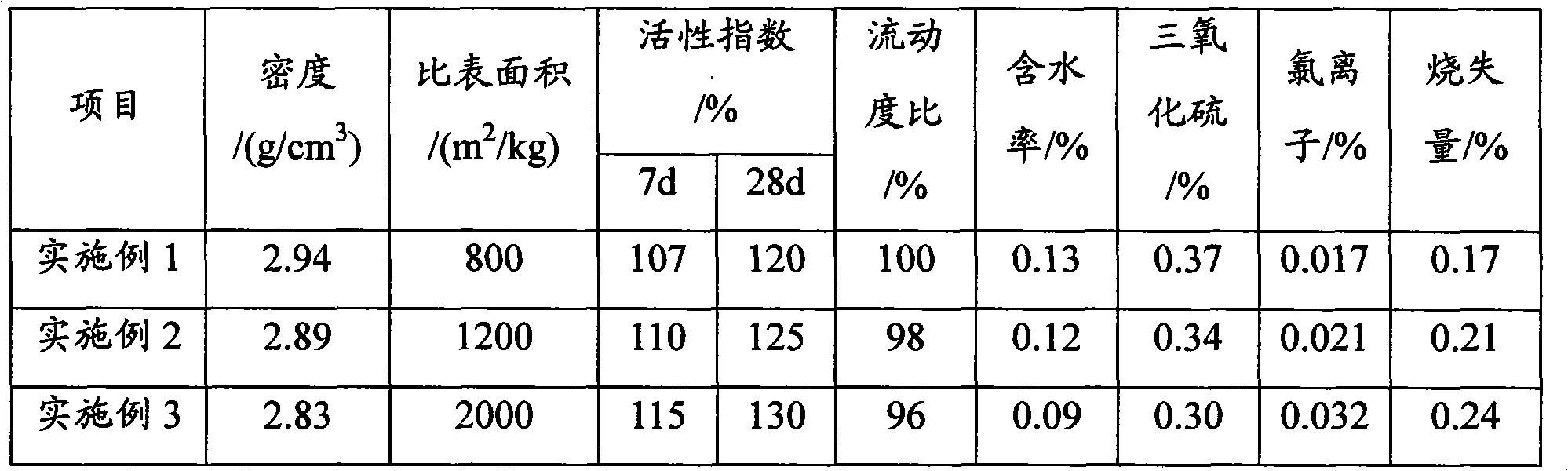

[0015] The super active slag powder of physical properties in the following table 1 is an example to further elaborate the present invention:

[0016]

SiO 2

CaO

Al 2 o 3

Fe 2 o 3

MgO

Specific surface area /

(m 2 / kg)

average grain

Diameter / μm

Example 1

32.23

37.43

11.17

0.93

11.15

800

4.2

Example 2

33.34

38.55

12.06

0.73

9.89

1200

3.8

Example 3

35.37

39.26

13.27

0.54

7.36

2000

2.0

[0017] The preparation method of the superactive slag powder of three embodiments of the present invention is as follows:

[0018] 1) Drying: Blast furnace slag is dried at a temperature of 105°C until the moisture content is less than or equal to 0.6%.

[0019] 2) Coarse grinding: grind the dried blast furnace slag with a vertical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com