Electro-hydraulic servo valve for prestage independent type jet flow pipe

A jet tube, self-contained technology used in servo motor assemblies, valve details, multi-port valves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

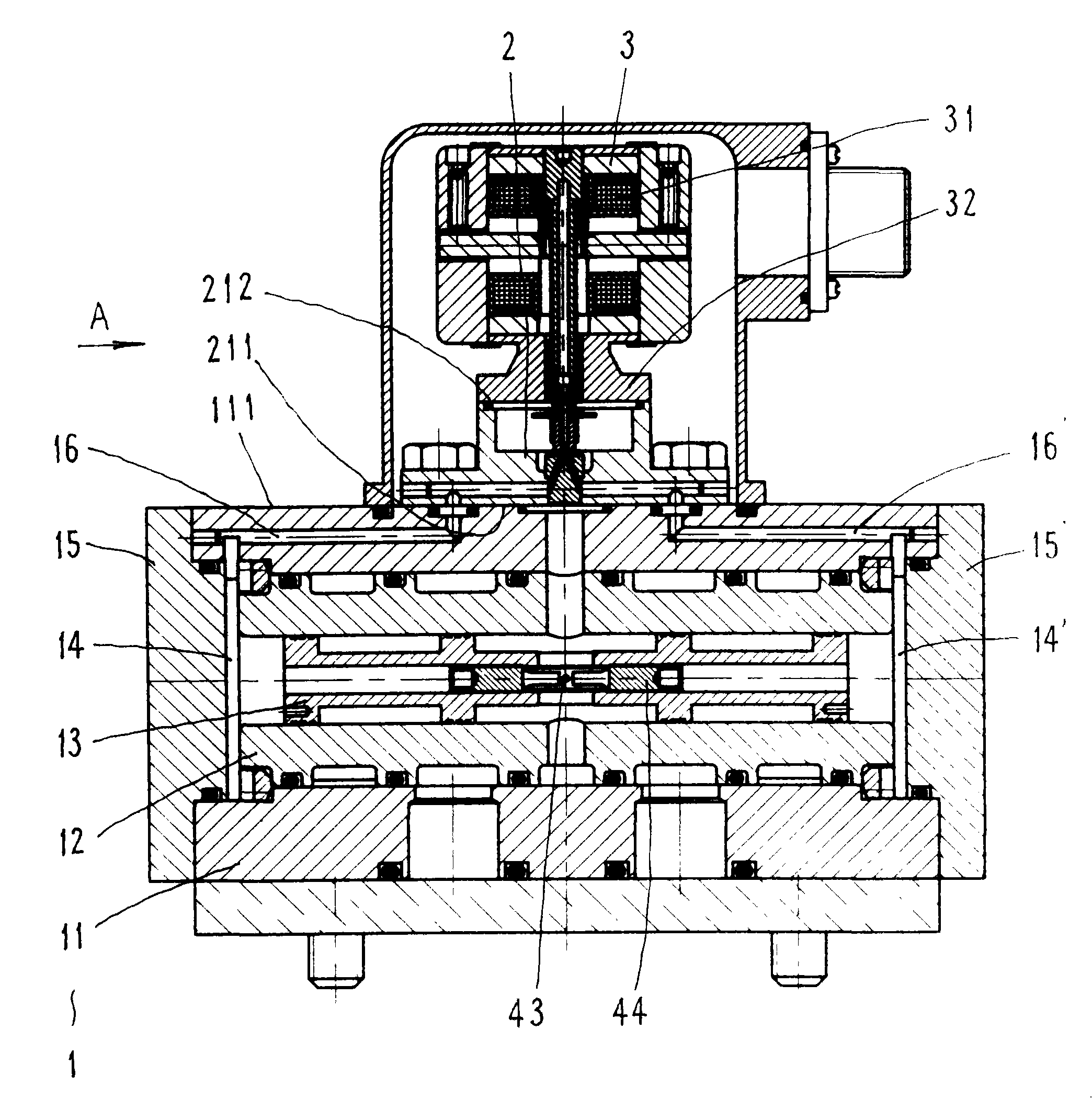

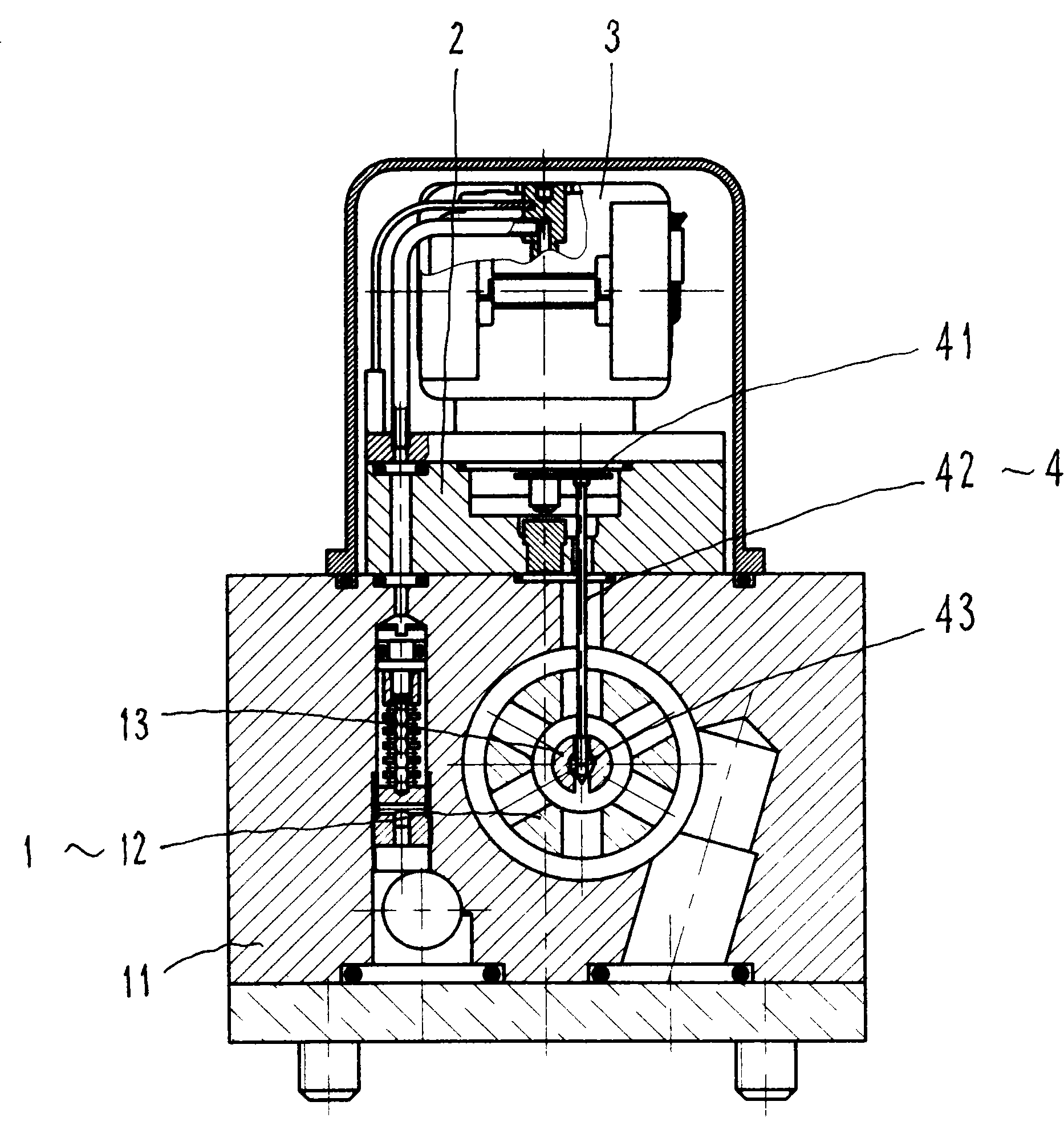

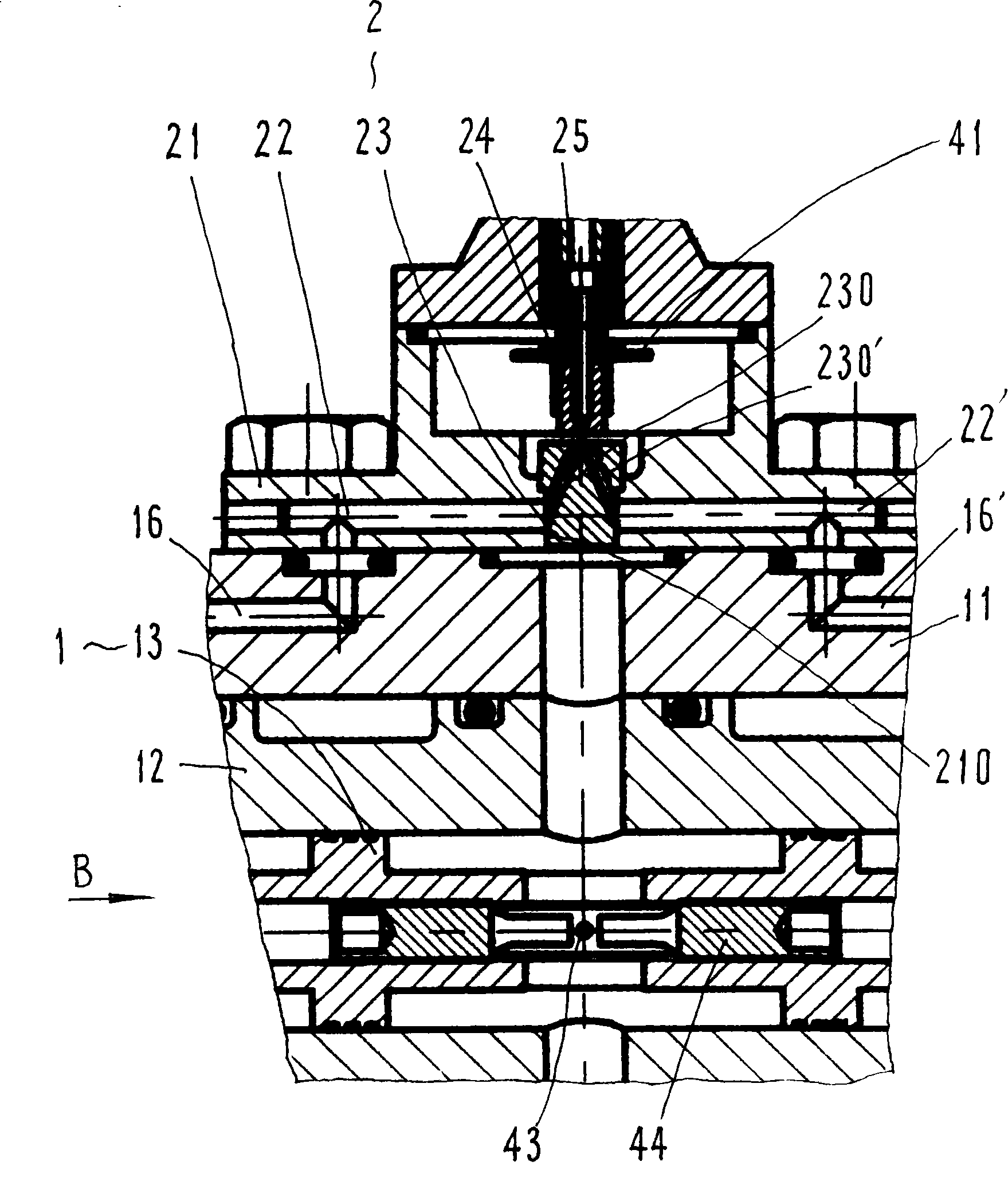

[0019] refer to figure 1 , 2 , 3, 4, the pre-independent jet tube electro-hydraulic servo valve includes a main valve 1, a pre-stage jet tube 2, a torque motor 3 and a feedback lever 4, and the valve body 11 of the main valve 1 is fixed with a pre-stage The jet tube 2, the pre-stage jet tube 2 is fixedly equipped with a torque motor 3, the upper end of the feedback lever 4 is connected to the pre-stage jet tube 2, the lower spherical end 43 of the feedback lever 4 is in contact with the adjusting bolt 44 of the main valve 1 .

[0020] Main valve 1, its main structure is similar to existing products, main valve 1 includes valve body 11, valve sleeve 12, valve core 13, left and right control chamber 14, 14', left and right pressure block 15, 15' and Left and right guide holes 16, 16', wherein:

[0021] The valve body 11 is provided with left and right guide holes 16, 16' on the side adjacent to the fixed pre-stage jet tube 2; Road, the left and right guide holes 16, 16 'can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com