Method for producing a catalyst layer

A technology of catalytic layer and catalyst, applied in the field of catalytic layer, to achieve the effect of improving uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

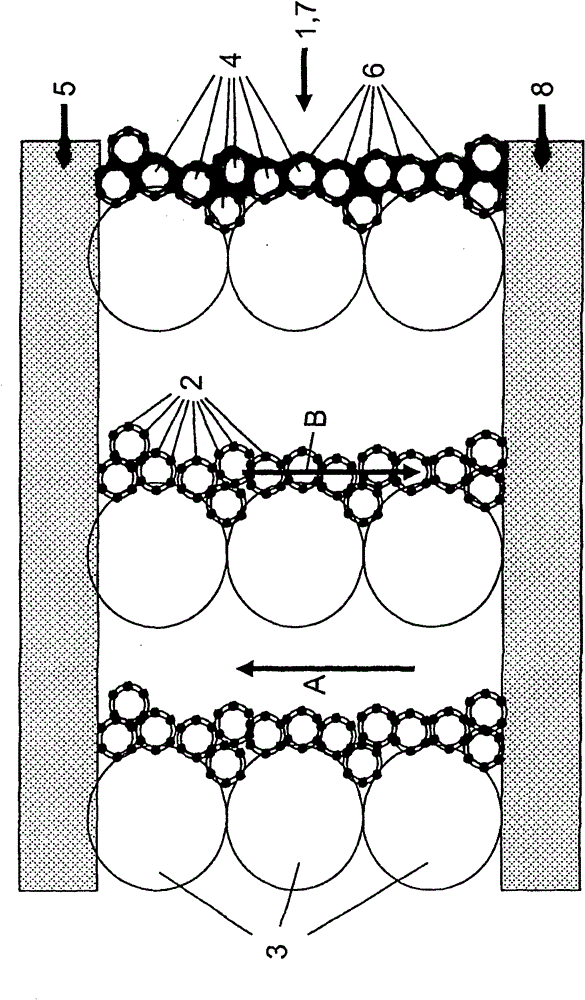

[0083] The catalyst layer 1 structured according to the invention contains many catalyst particles 2 of the order of 1.5 nm that are electrochemically deposited from a platinum salt, wherein, prior to the electrochemical deposition, larger conductive carbon particles 3 (average diameter of about 50 nm ) and smaller conductive carbon particles 4 (average diameter about 8 nm), applied to the gas diffusion layer used as the substrate by coating the precursor solution containing the particles 3, 4 on the substrate 5, and then press the precursor layer tightly on the substrate 5. Larger particles 3, which advantageously have a high graphite fraction and thus a hydrophobic surface, serve to form the coarse structure, while smaller particles here are impregnated with an electrolyte material 6 (here Nafion) and are thus almost completely covered by the electrolyte material 6 4 is used to form fine structures. Particles 3, 4 ensure the necessary electrical conductivity and constitute ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com