Combined type mechanized processing production process of frozen minced fillet

A technology of frozen surimi and production process, applied in fish processing, slaughtering, food science, etc., can solve the problems of low degree of mechanization, no processing technology, and many operators, so as to implement mechanized processing operations and improve the level of production technology , suitable for a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with specific fish species, the combined mechanized processing and production process of frozen surimi of the present invention will be described step by step.

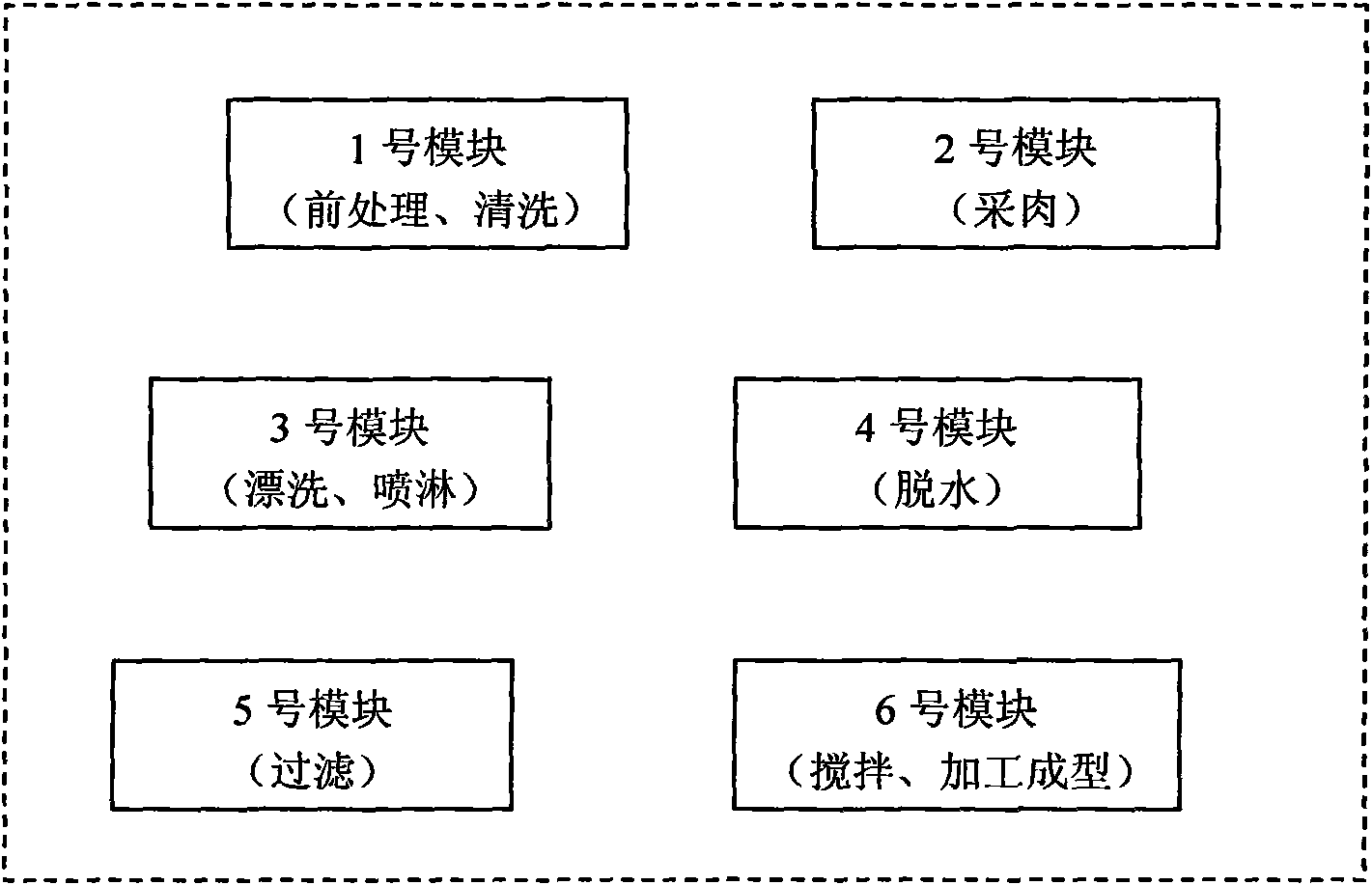

[0039] Such as figure 1 As shown, it is six process modules of the frozen surimi combined mechanized processing production process of the present invention. When these six process modules are combined into a specific frozen surimi mechanized processing production process for a certain fish species, the order is adjustable. A specific module is reusable, and a specific module is not required.

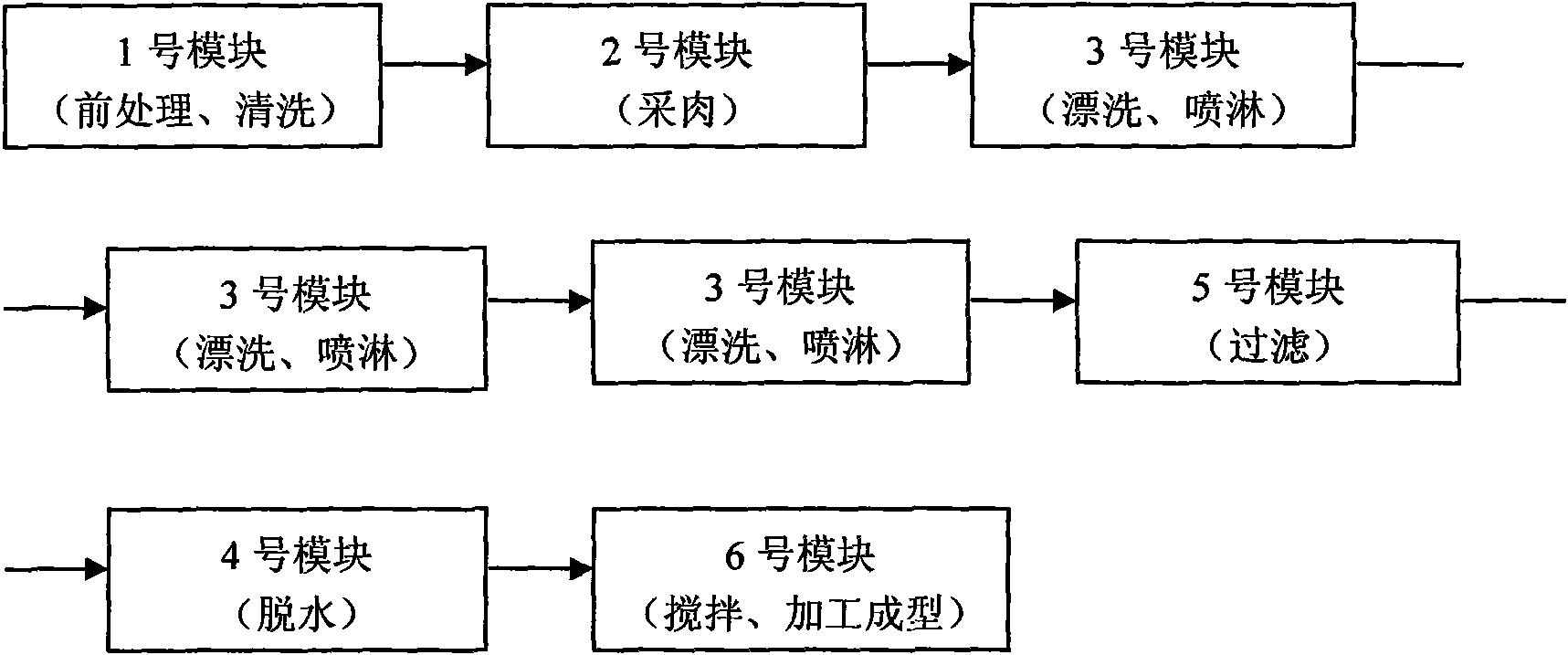

[0040] Such as figure 2As shown, for sea fish with larger individual, more fat, and fewer fish bones and fish bones, such as pollock, the frozen surimi processing adopts No. 1 module → No. 2 module → No. 3 module → No. 3 module → No. 3 module → Module No. 5 → Module No. 4 → Module No. 6, in which Module No. 3 has been used 3 times, that is, the minced fish collected by Module No. 2 needs to be rins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com