Express-melting silicon additive and preparation method thereof

An additive and fast-melting silicon technology, applied in the field of material science and casting, can solve the problems of difficult to accurately control the target composition, incomplete melting of crystalline silicon, and affecting the quality of molten aluminum, etc., to achieve easy large-scale integrated production and easy control of alloy components , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

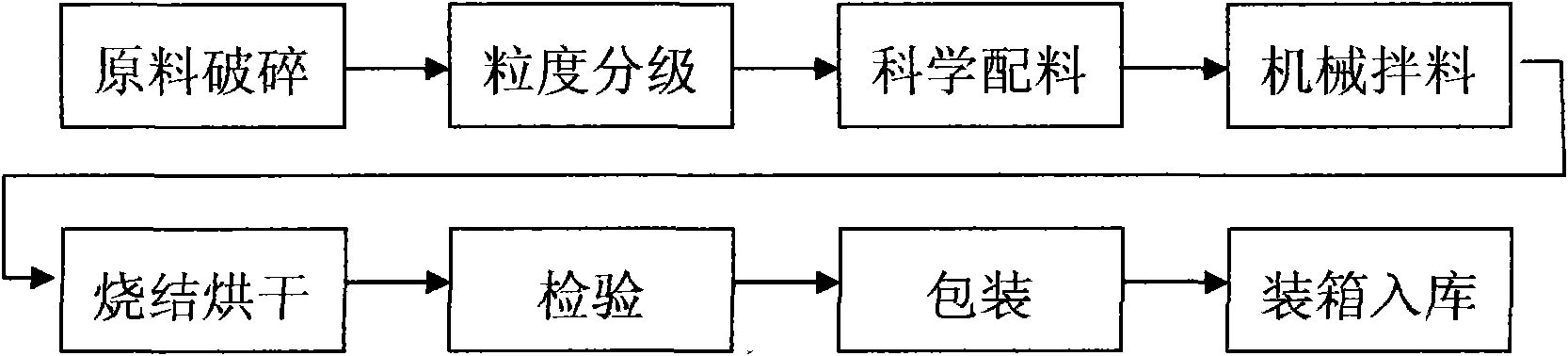

Method used

Image

Examples

Embodiment 1

[0071] Choose metal silicon silicon blocks with a silicon content of 95%, through manual or mechanical crushing and grading, select 93kg of silicon blocks with a particle size of 20-80mm (wherein the powder is 1%), and use 1kg of potassium fluoride as a flux. 1kg of titanium dioxide is used as a modifier, and 5kg of kaolin and water are used as a binder.

[0072] According to the mass percentage, it is: 1% of flux, 1% of modifier, 5% of binder, and the rest is silicon block. Stir evenly in a high-speed mixer. After fully mixing and stirring evenly, take the resulting mixture out of the mixing drum, put it into a sintering drying furnace, pass in steam, slowly raise the temperature to 120-220°C, keep it warm for 2-8h, and then slowly cool to At room temperature, the fast-melting silicon additive of the present invention can be obtained.

Embodiment 2

[0074] Select metal silicon silicon blocks with a silicon content of 95%, manually or mechanically crush and classify, and select 93kg of silicon blocks with a particle size of 20-80mm (including 1% powder), and use 1kg of potassium fluoroaluminate as a flux , using 1kg of hexachloroethane as modifier, and 5kg of refractory clay and water as binder.

[0075] According to the mass percentage, it is: 1% of flux, 1% of modifier, 5% of binder, and the rest is silicon block. Stir evenly in a high-speed mixer. After fully mixing and stirring evenly, take the resulting mixture out of the mixing drum, put it into a sintering drying furnace, pass in steam, slowly raise the temperature to 120-220°C, keep it warm for 2-8h, and then slowly cool to At room temperature, the fast-melting silicon additive of the present invention can be obtained.

Embodiment 3

[0077] Select metal silicon silicon blocks with a silicon content of 95%, manually or mechanically crush and classify, select 93kg of silicon blocks with a particle size of 20-80mm (including 1% powder), and use 1kg of potassium fluorosilicate as a flux , with sodium fluoride 1kg as modifier, talcum powder and water 5kg as binder.

[0078] According to the mass percentage, it is: 1% of flux, 1% of modifier, 5% of binder, and the rest is silicon block. Stir evenly in a high-speed mixer. After fully mixing and stirring evenly, take the obtained mixture out of the mixing drum, put it into a sintering drying furnace, pass in steam, slowly raise the temperature to 120-220°C, keep it warm for 2-8h, and then slowly cool to At room temperature, the fast-melting silicon additive of the present invention can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com