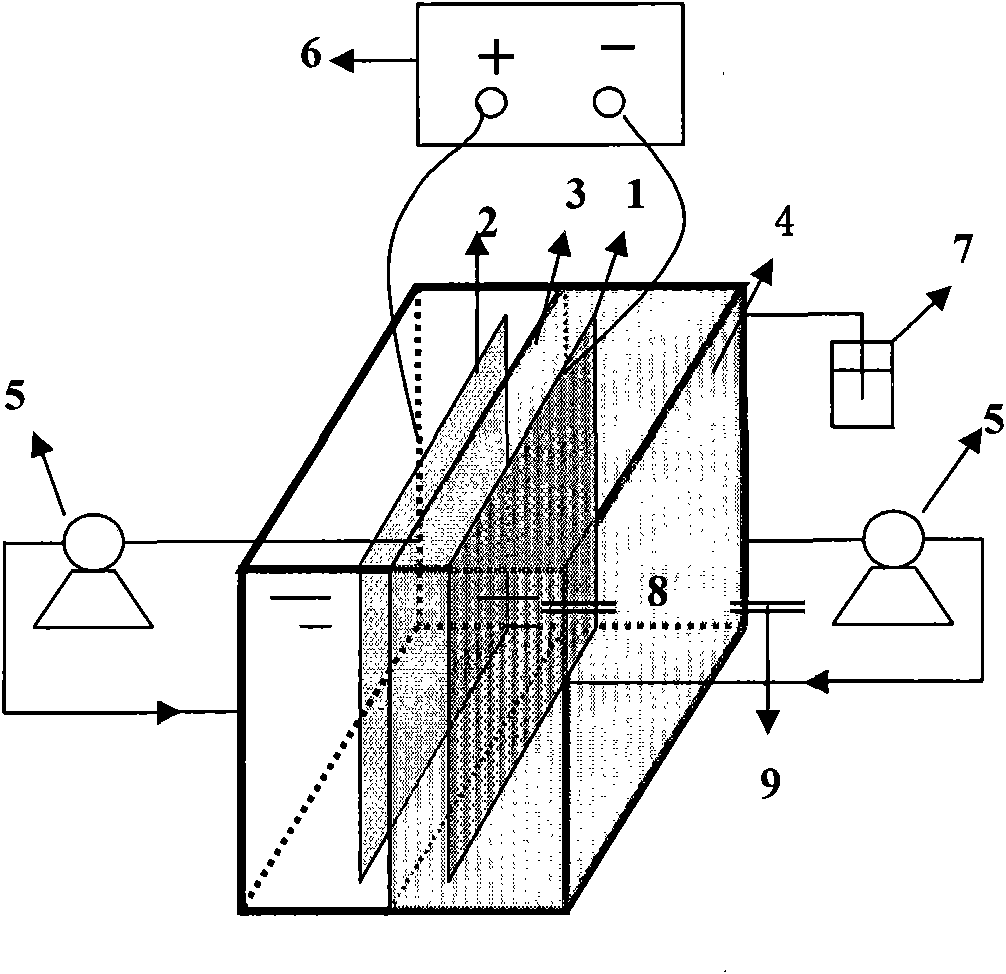

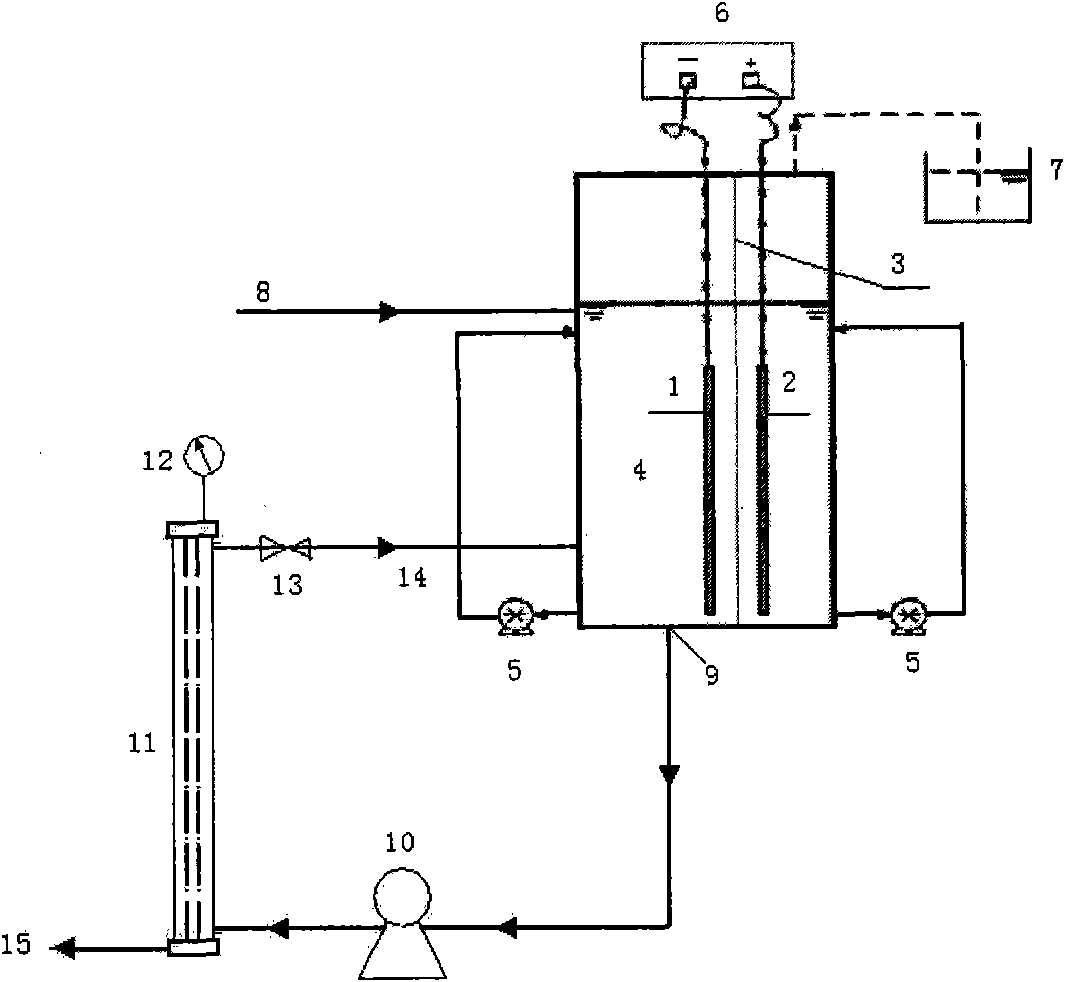

Method and reactor for removing nitrate through membrane electrolysis electrochemical hydrogen autotrophic denitrification

An autotrophic denitrification and nitrate technology, applied in chemical instruments and methods, anaerobic digestion treatment, water/sewage multi-stage treatment, etc., can solve the problem of reactor load reduction, achieve volume load increase, and avoid microbial pollution , to avoid the effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Apply 0.03mol / L of H to the anode chamber 2 SO 4 Ensure that the effluent of the cathode chamber is neutral, and the effective volume of the reactor is 3.0L. will contain NO 3 - -N 30mg / L wastewater enters the membrane electrolysis electrochemical hydrogen autotrophic membrane bioreactor from the water inlet, the applied current is 250mA, the residence time is 5h, the sludge concentration is 1000-2000mg / L, the system treats the effluent, SS is not detected out, reactor NO 3 - -N removal rate > 90%, and no NO 2 - accumulation.

Embodiment 2

[0022] The operating conditions are the same as in Example 1, except that when the applied current is 300mA, the residence time is 4h, and the sludge concentration is 1000-2000mg / L, the system treats the water, SS is not detected, and the reactor NO 3 - -N removal rate > 90%, and no NO 2 - accumulation.

Embodiment 3

[0024] The operating conditions are the same as in Example 1, except that when the applied current is 400mA, the residence time is 3h, and the sludge concentration is 1000-2000mg / L, the system treats the water, SS is not detected, and the reactor NO 3 - -N removal rate > 90%, and no NO 2 - accumulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com