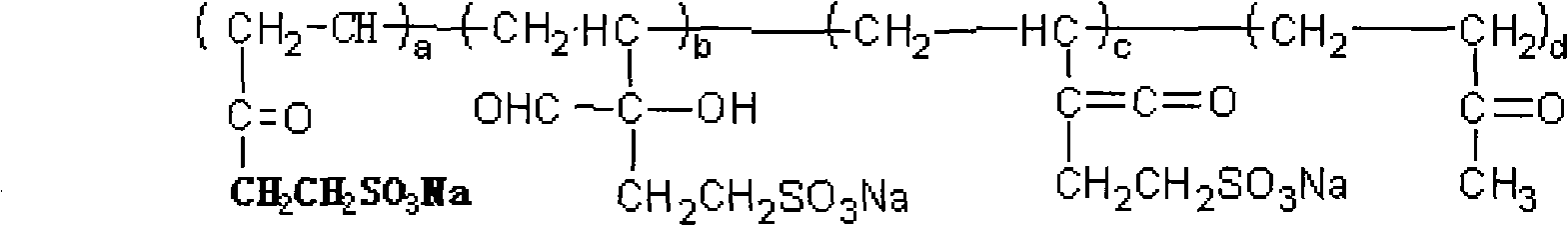

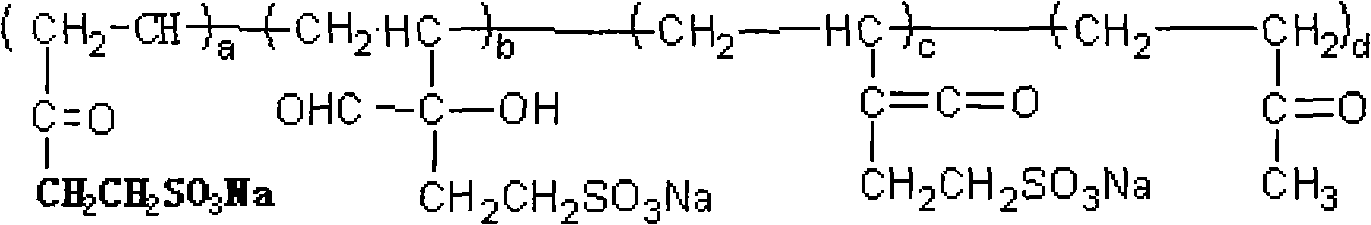

Aliphatic series high-efficiency water reducing agent and preparation method thereof

A high-efficiency water-reducing agent, aliphatic technology, applied in the preparation of sulfonates, organic chemistry, etc., can solve the problems of long reaction period and uneven molecular weight distribution of reaction products, achieve stable reaction, avoid bumping and gelling phenomenon , the effect of a significant increase in strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Raw material weight ratio is

[0028] Anhydrous sodium sulfite: 15.5%

[0029] Acetone: 13%

[0030] Mass concentration 37% formaldehyde solution: 32%

[0031] Water: 39.5%;

[0032] The specific operation process is as follows:

[0033] Add water and anhydrous sodium sulfite into the reaction vessel, add acetone and stir under reflux for 30 minutes at a temperature below 20°C, add formaldehyde solution with a mass concentration of 37% into the reaction vessel dropwise, control the dripping reverse speed to complete the dropwise addition in 2 hours, and then heat Raise the temperature to 80° C., and react at constant temperature for 3 hours to obtain a brown-red liquid finished aliphatic high-efficiency water reducer with a mass concentration of 35%.

Embodiment 2

[0035] Raw material weight ratio is

[0036] Anhydrous sodium sulfite: 5%

[0037] Acetone: 13%

[0038] Mass concentration 37% formaldehyde solution: 32%

[0039] Water: 50%;

[0040] The specific operation process is as follows:

[0041] Add water and sodium sulfite into the reaction vessel, add acetone at a temperature below 40°C, stir and reflux for 60 minutes, add the formaldehyde solution with a mass concentration of 37% dropwise into the reaction vessel of the first step, and control the reverse speed of the dropping to complete the dropwise addition in 1 hour. Then heat up to 120° C. and react at constant temperature for 6 hours to obtain a brown-red liquid finished aliphatic high-efficiency water reducer with a mass concentration of 40%.

Embodiment 3

[0043] Anhydrous sodium sulfite: 17.58%

[0044] Acetone: 9.89%

[0045] 37% formaldehyde solution with mass concentration: 28.57%

[0046] Water: 43.96%,

[0047] The specific operation process is as follows:

[0048] Add water and anhydrous sodium sulfite into the reaction vessel, add acetone and stir under reflux for 30 minutes at a temperature below 20°C, add formaldehyde solution with a mass concentration of 37% into the reaction vessel dropwise, control the dripping reverse speed to complete the dropwise addition in 2 hours, and then heat Raise the temperature to 80° C., and react at constant temperature for 3 hours to obtain a brown-red liquid finished aliphatic high-efficiency water reducer with a mass concentration of 35%.

[0049] The main technical performance index of the product prepared by the present invention is as follows:

[0050] 1. Brown-red liquid in appearance; solid content > 30%; specific gravity 1.15-1.2

[0051] 2. High water reduction rate. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com