Quartz glass crucible and silicon single crystal pulling method using same

A technology of quartz glass crucible and silicon single crystal, which is applied in the directions of self-melting pulling method, single crystal growth, single crystal growth, etc. It can solve the problems of large influence of quartz glass and insufficient research on the influence of pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

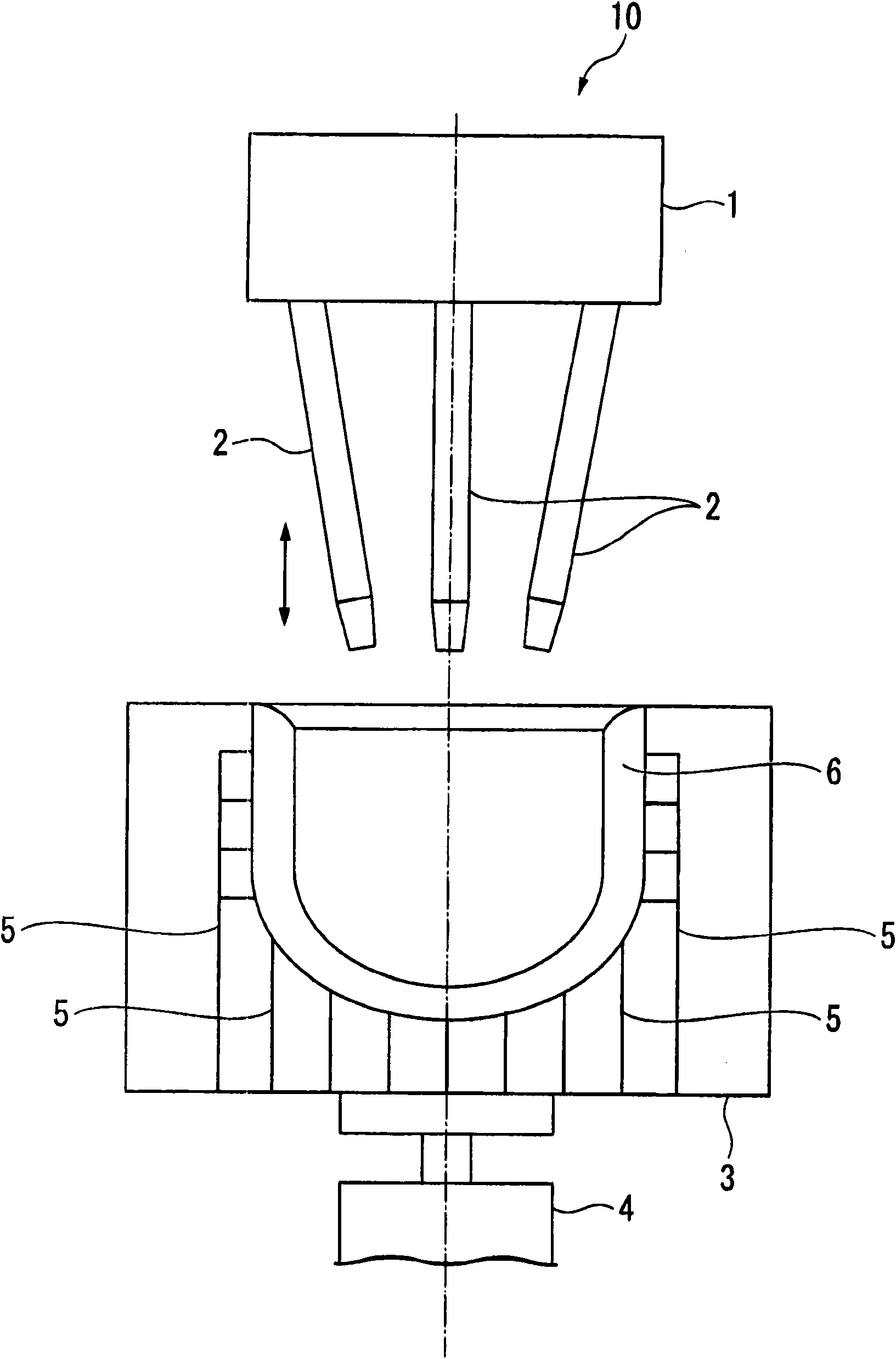

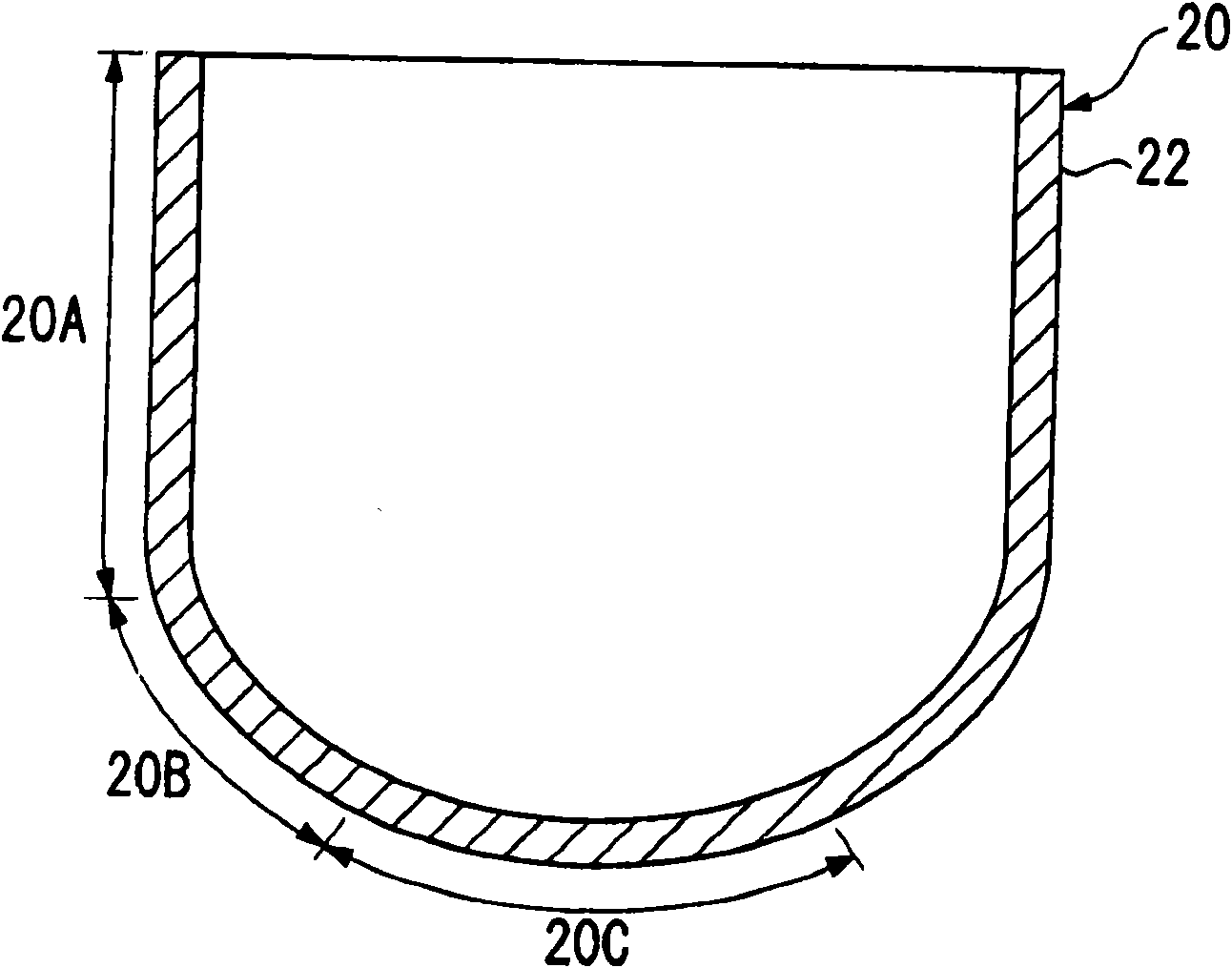

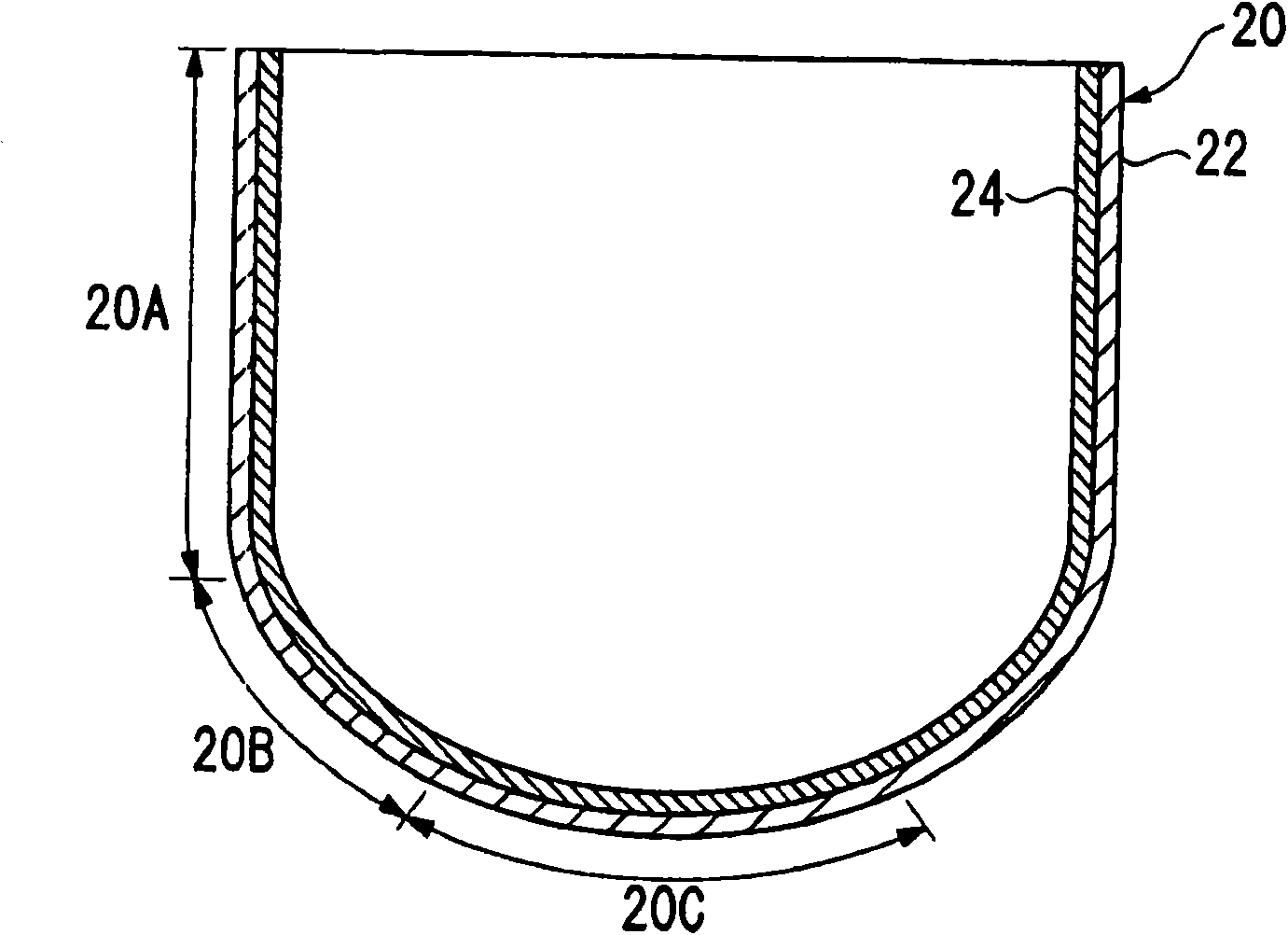

Method used

Image

Examples

Embodiment 1~3、 comparative example 1~6

[0097] Using a quartz glass crucible (diameter of 28 inches) shown in Table 1, the silicon single crystal was pulled with a furnace pressure of 40 torr, an argon atmosphere, and a pulling time of 100 hr.

[0098] The results are shown in Table 1.

[0099] In addition, in Table 1, the inner surface crystallization ratio (%) is the proportion of crystalline silicon produced by crystallization of amorphous silicon on the inner surface of the crucible.

[0100] Open cell density (count / mm 2 ) is the inner surface density of the crucible in the concave part generated by open bubbles.

[0101] The rate of melting loss (μm / h) is the rate at which the thickness of the inner surface of the crucible decreases.

[0102] The void content rate (%) is the number of voids contained in one wafer.

[0103] Examples 1-3 are quartz glass crucibles of the present invention, and Comparative Examples 1-6 are quartz glass crucibles outside the scope of the present invention.

[0104] The inner s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com