Production method of chargeable lithium polymer battery for simultaneously low-temperature discharge and heavy-current discharge

A high-current discharge and production method technology, which is applied in the direction of secondary batteries, electrochemical generators, circuits, etc., can solve the problem that military equipment is not well used, and achieve the goal of increasing discharge power and service life and reducing weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

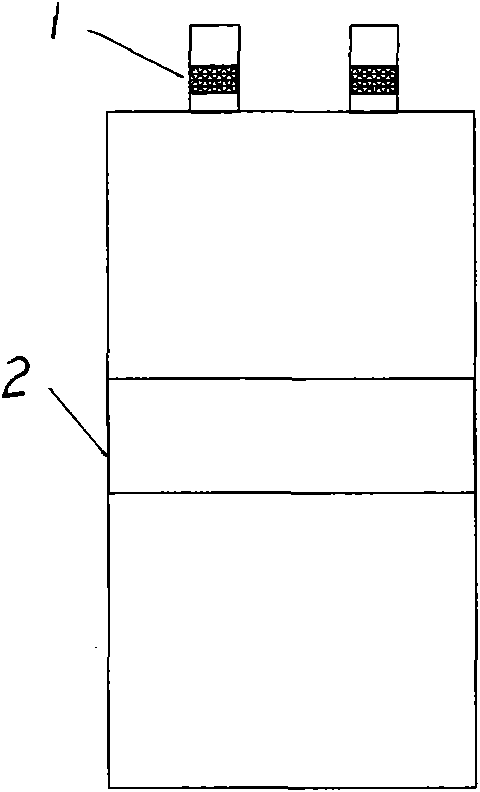

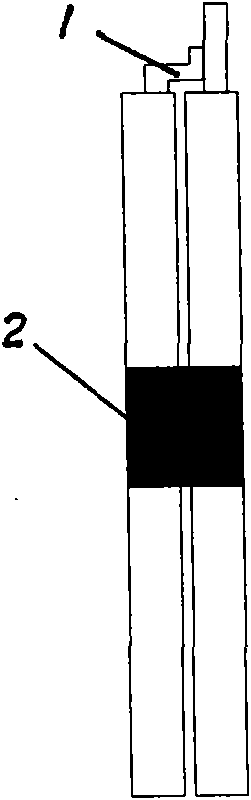

Image

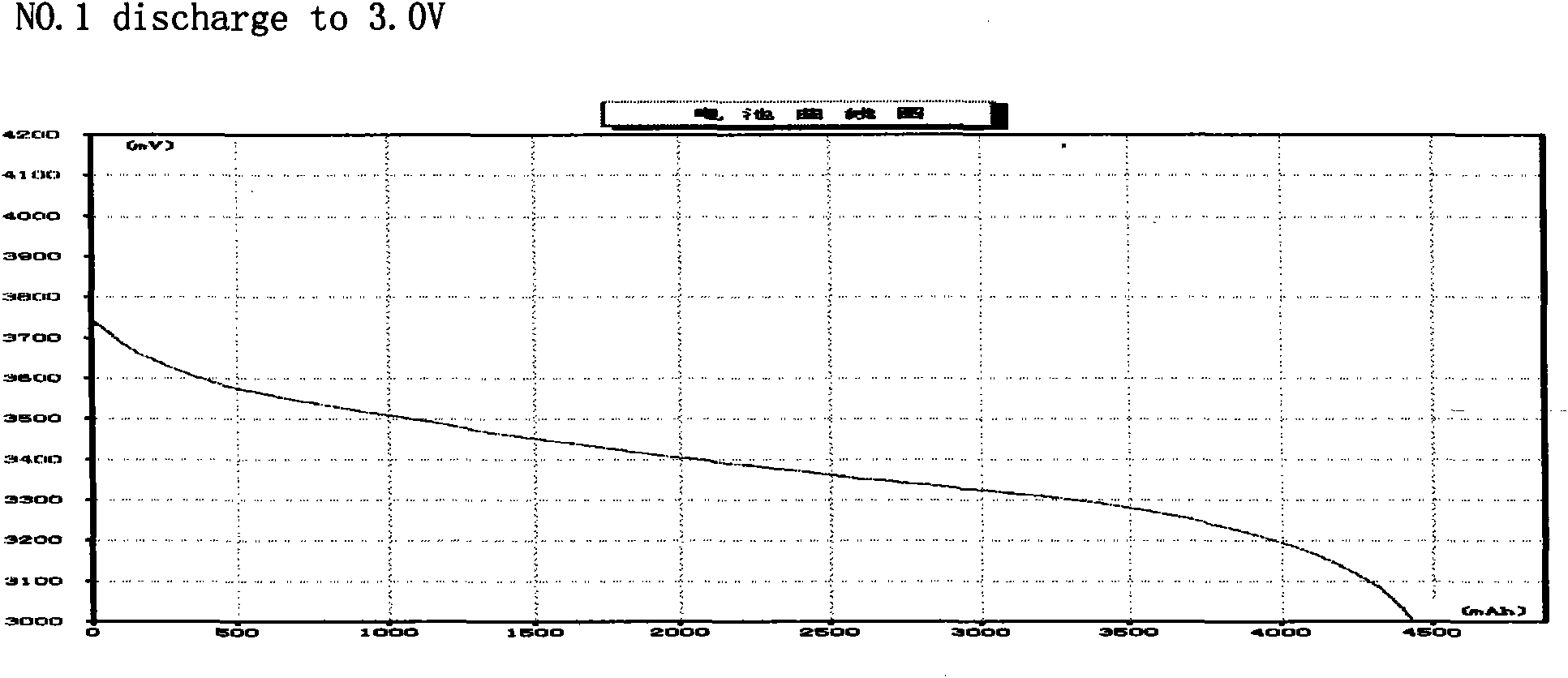

Examples

Embodiment Construction

[0058] A method for producing a lithium polymer rechargeable battery for both low-temperature discharge and high-current discharge. Specifically adopt following technical scheme, it comprises the steps:

[0059] 1. Preparation of positive electrode:

[0060] A. After mixing the raw materials according to the following weight ratio, dissolve the polyvinylidene fluoride binder with N-methylpyrrolidone as the colloidal masterbatch to prepare the positive electrode slurry,

[0061]B. The powder is obtained according to the following weight ratio, wherein the doped and modified lithium manganate through secondary purification accounts for 6.8 parts and nickel-cobalt-manganese oxide accounts for 3 parts, and the above-mentioned mixture accounts for the total powder weight: 97.4%, Conductive carbon black accounts for 2.1% of the total powder weight, and nanometer ultra-long carbon fiber accounts for 0.5% of the total powder weight.

[0062] C. First disperse and mix the above powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com