Heat dissipating device for cooling machine cabinet

A heat dissipation device and cabinet technology, which is applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems that the cabinet heat dissipation device occupies a large space, has low heat dissipation effect, and cannot be processed, so as to shorten the working process, save energy consumption, and shorten the path Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

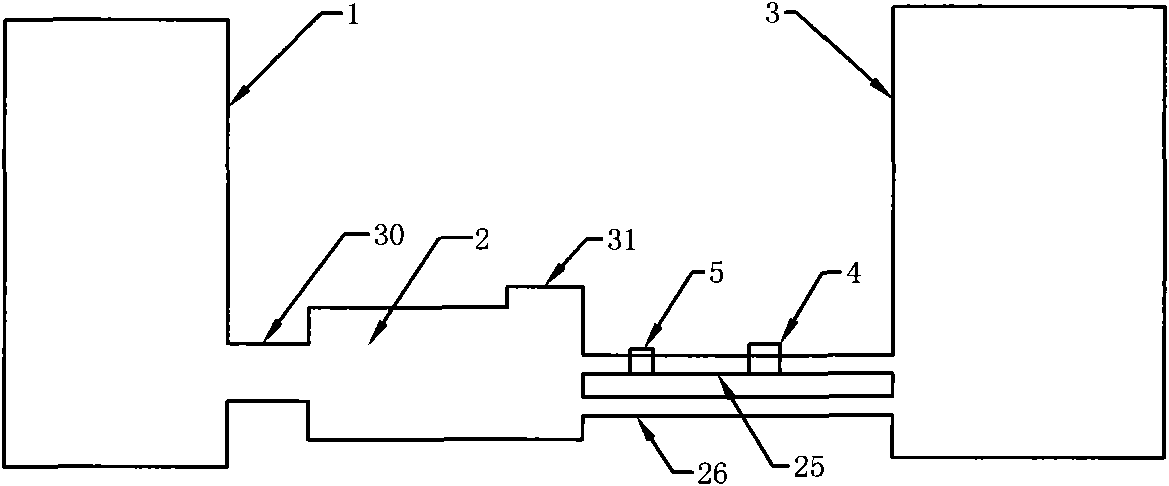

[0027] Such as figure 1 As shown, the heat dissipation device of the technical solution of the present invention includes an outdoor refrigeration unit 3 , a hot air suction device 1 , a water cooling circulation device 2 and a circulation pipeline, and the circulation pipeline includes a water inlet pipe 25 and a water outlet pipe 26 .

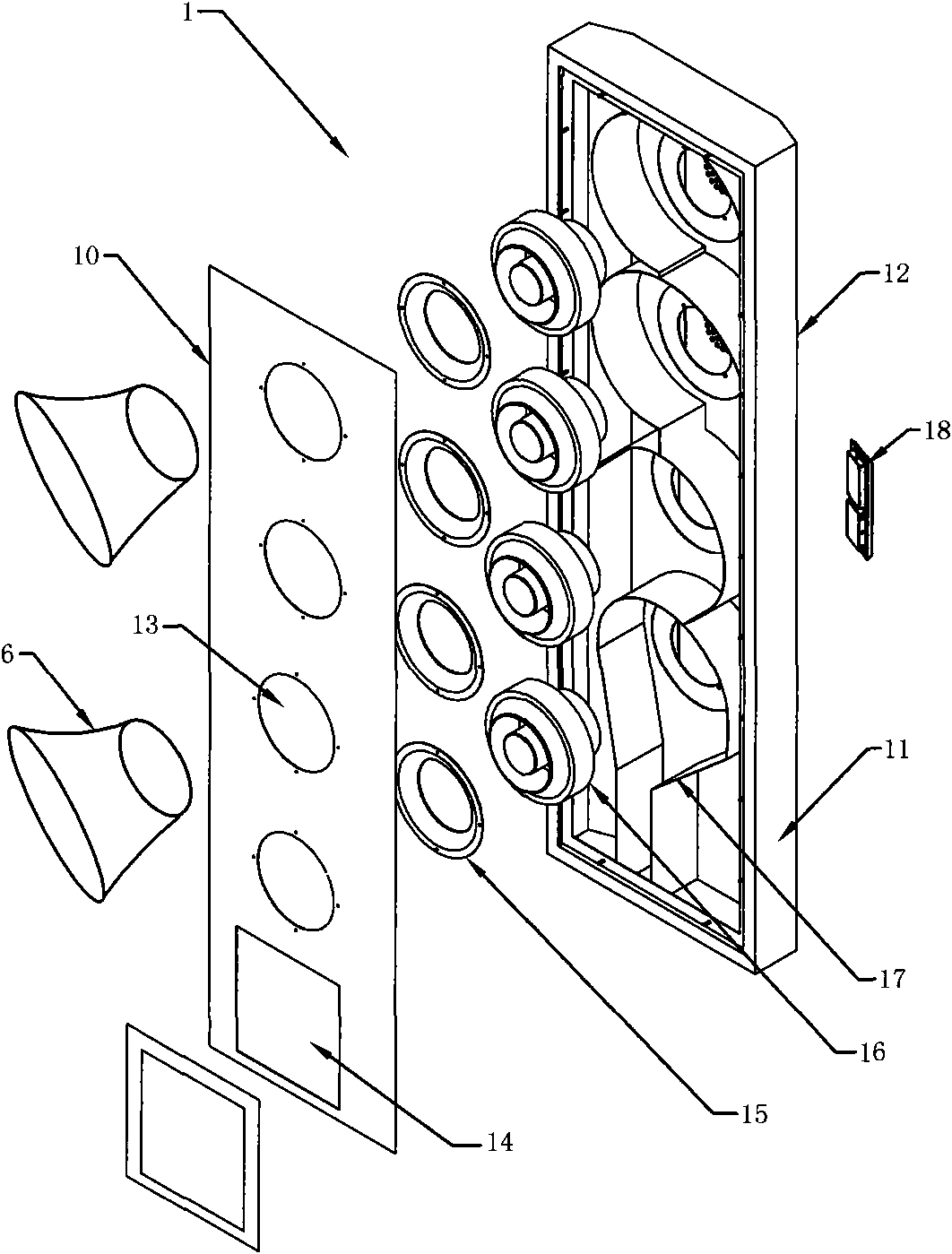

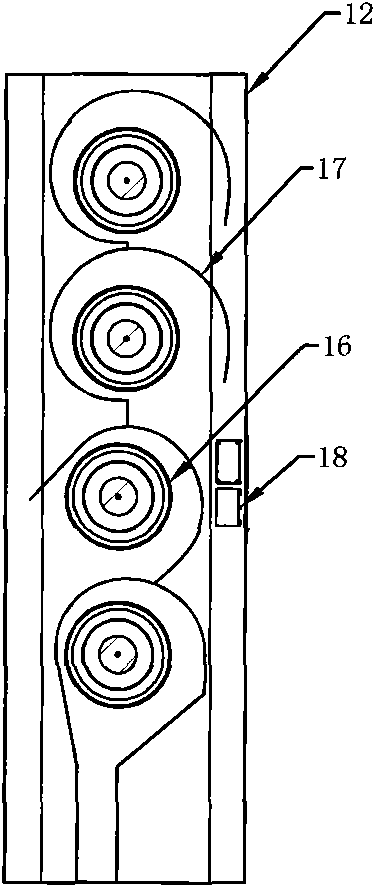

[0028] Such as figure 2As shown, the hot air suction device 1 adopts a box-shaped structure, including a front sealing plate 10, a frame 11, and a rear sealing plate 12. After the front and rear plates and the frame are closed, the device is integrally sealed. The air inlet 13, of course, the position of the air inlet does not have to be fixed on the central axis, it can be opened at any position of the box body in terms of the setting of the air suction and the internal air duct, and the number of air inlets also depends It can be increased or decreased according to actual needs. A suction fan 16 is installed inside the box, and the posit...

Embodiment 2

[0039] Such as figure 2 As shown, on the basis of Embodiment 1, the technical solution is also equipped with a suction ring 6 at the suction port 13, and the suction ring extends outward to align with the heat source, and the suction ring 6 can be folded to buckle on the heat source, so that The wind force of the suction fan can directly suck away the high temperature generated by the heat source, instead of absorbing it after it is dissipated.

Embodiment 3

[0041] On the basis of Embodiment 1, this technical solution can install multiple suction fans 16 in the same air suction port 13 to adapt to heat sources at the same height and different positions, so that each heat source has a corresponding suction fan to work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com