Power saving device for controlling production processes of silicon carbide smelting furnace system by rated value method

A technology for controlling silicon carbide and power-saving devices, applied in electric heating devices, heating by discharge, chemical industry, etc., can solve the problems of waste of electric energy, high level, and low product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

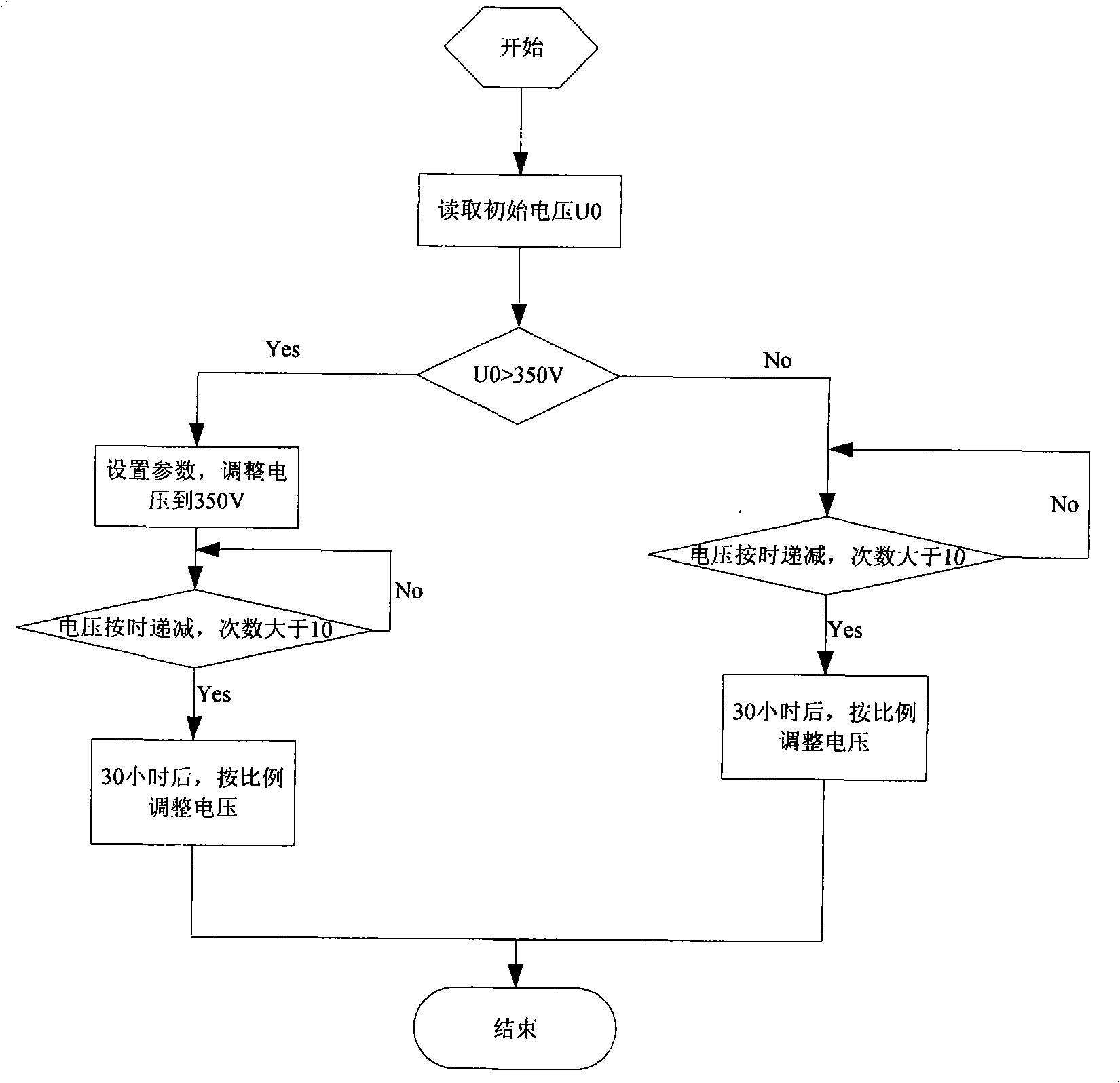

[0042] The present invention will be further described below in conjunction with the accompanying drawings.

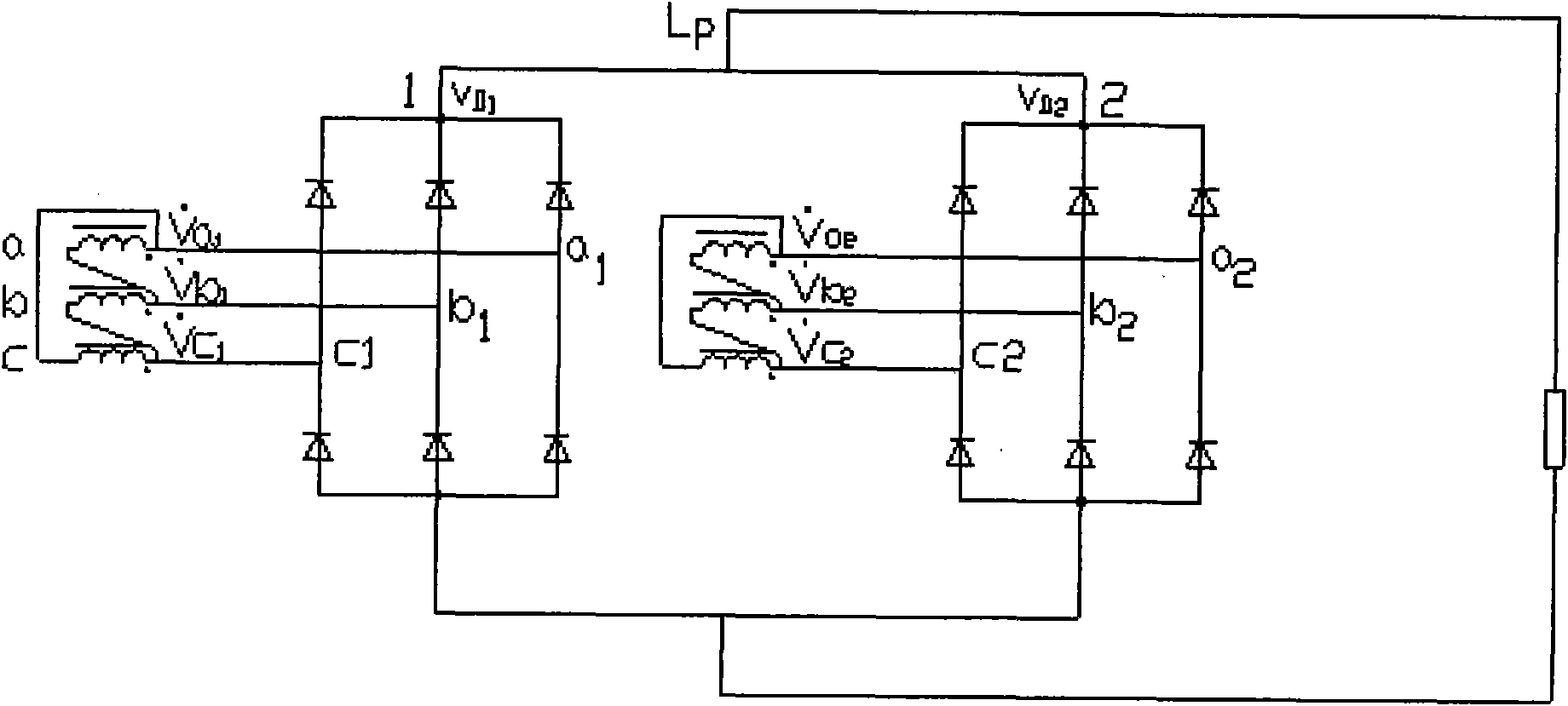

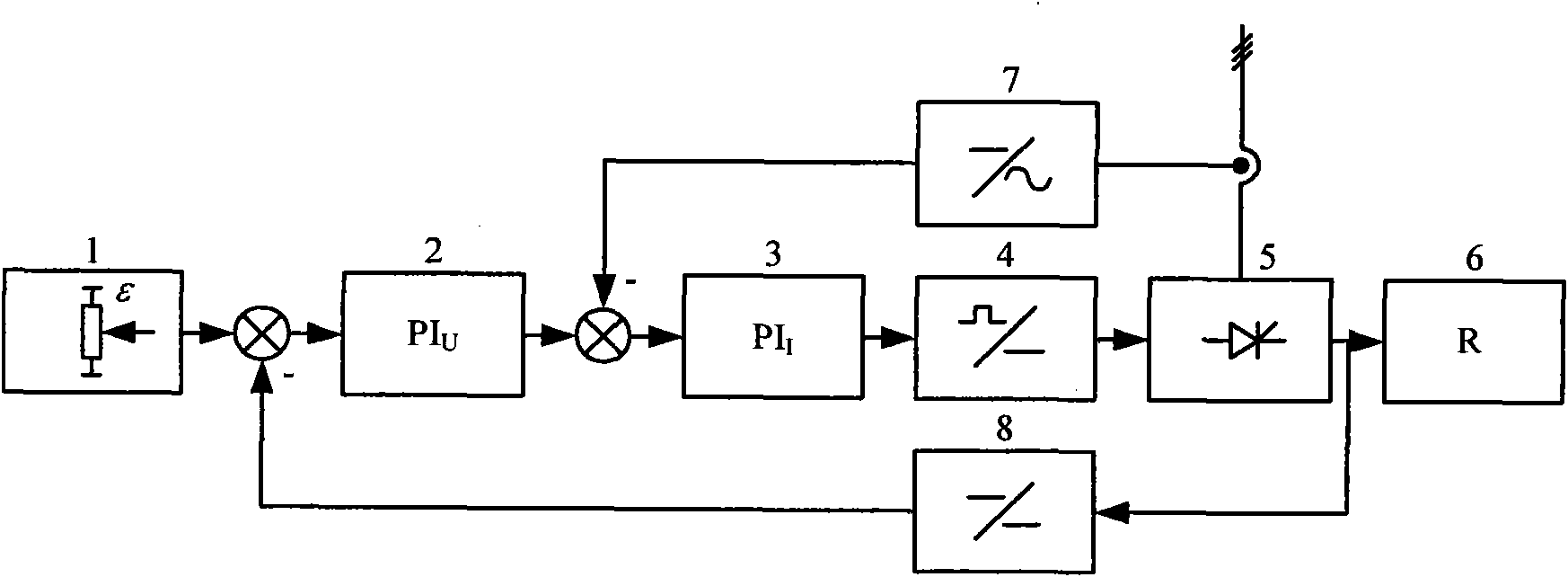

[0043] A power-saving device for controlling the production process of a silicon carbide smelting furnace system by a rated value method, the power-saving device includes an embedded computer automatic setting control module 1, a voltage regulator 2, a current regulator 3, a trigger 4, a rectifier 5, Sampling rectifier 7, converter 8, etc.; its signal control process is:

[0044] ①. The given control command signal is sent by the embedded computer automatic given control module 1, and the signal is sent to the voltage regulator 2. At the same time, the collected signal at both ends of the load 6 is also fed back to the voltage regulator 2 through the converter 8. , compare the two to get a voltage difference;

[0045] 2. After the voltage difference is regulated by the voltage regulator 2, its current signal is sent into the current regulator 3. At the same time, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com