Integral high frequency rectifying device

A high-frequency rectification and high-frequency transformer technology, applied in the field of power supply, can solve the problems of overheating of surrounding conductors, easy to burn rectifier tubes, failures at the connection, etc., and achieve the effects of reliable performance, good cooling effect, and improved heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

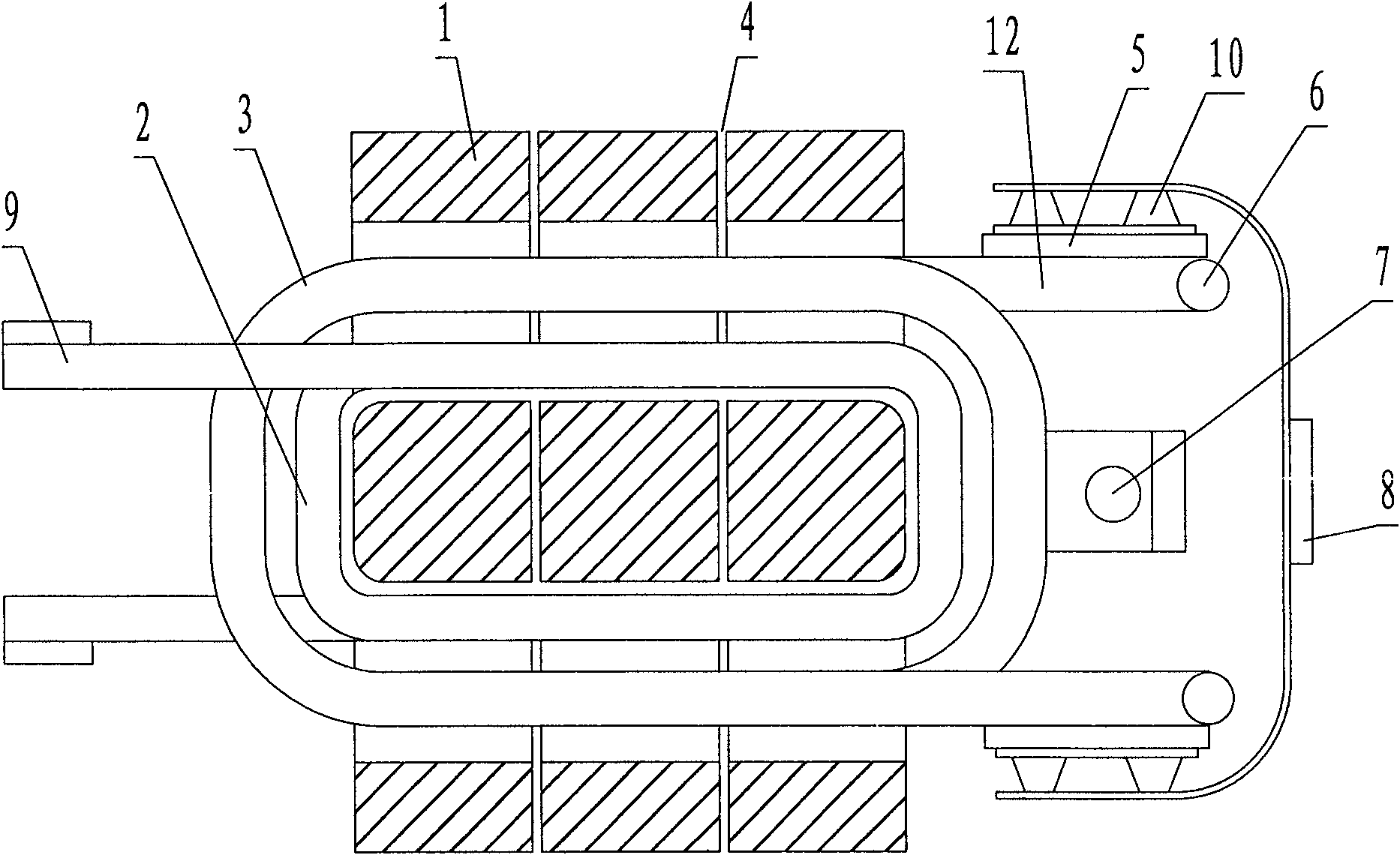

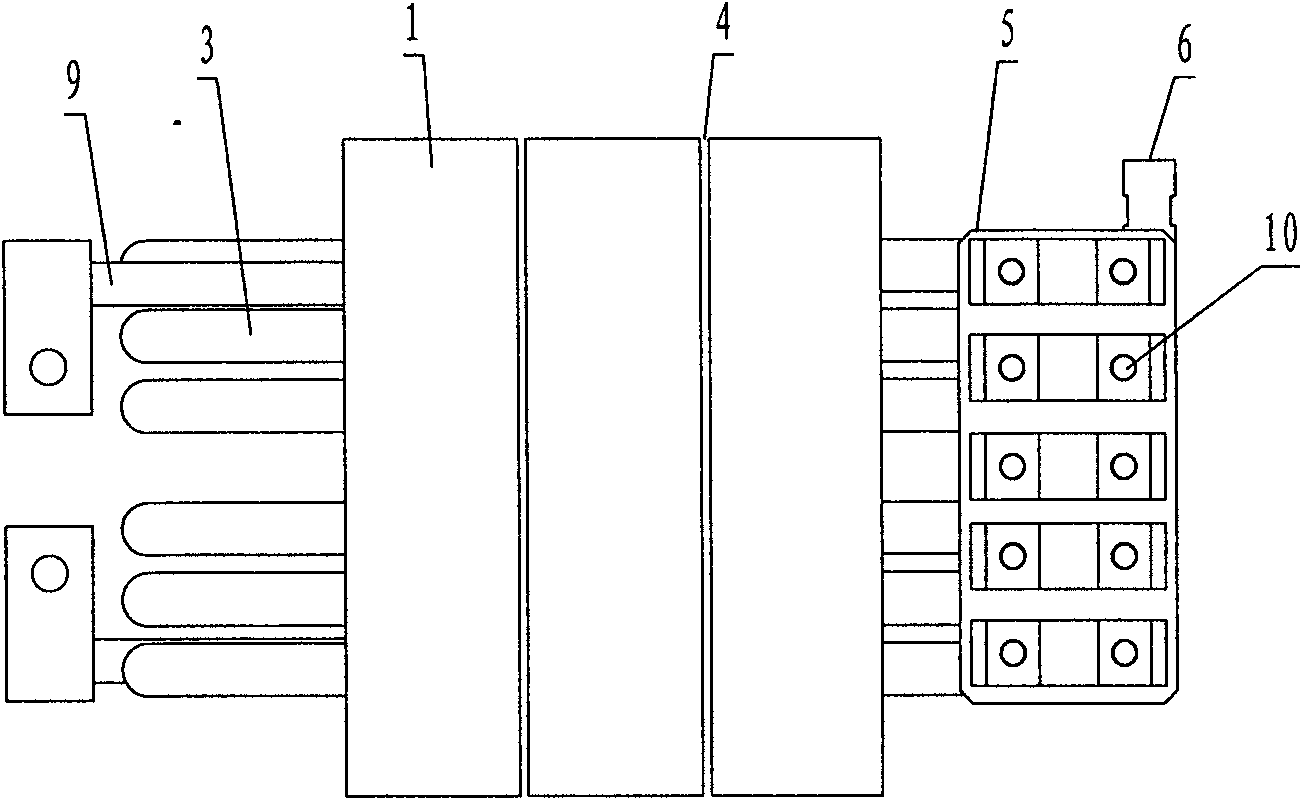

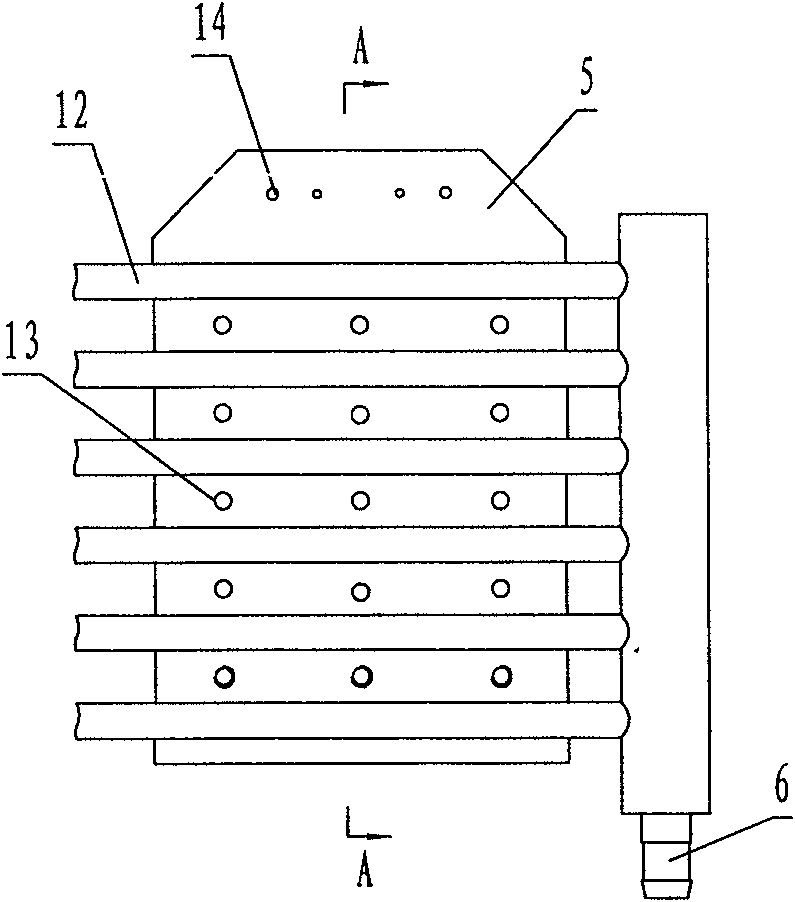

[0023] see Figure 1 ~ Figure 2 , the present invention combines the high-frequency transformer and the high-frequency rectifier together, and adopts the DC bus copper bar to lead out after the rectification, so there is no leakage inductance of the high-current lead wire of the high-frequency transformer and additional heating problems caused by high-frequency induction.

[0024] In order to solve the problem of high-power and high-current winding, the primary winding 2 and secondary winding 3 of the high-frequency transformer are made of copper or aluminum tubes, and the thickness of the tube wall is directly related to the frequency of the high-frequency inverter. Considering the skin effect and making full use of the conductor cross section. The primary winding of the high-frequency transformer is wound in series with 2 turns, and the secondary winding 3 is wound in parallel. The end of the coil is welded to the cooling plate 5 of the high-frequency rectifier. The interior...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com