Technique for atomic layer deposition

An atomic layer and atomic technology, applied in coating, metal material coating process, gaseous chemical plating, etc., can solve problems such as difficult to achieve dopant uniformity, damage, film compliance doping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

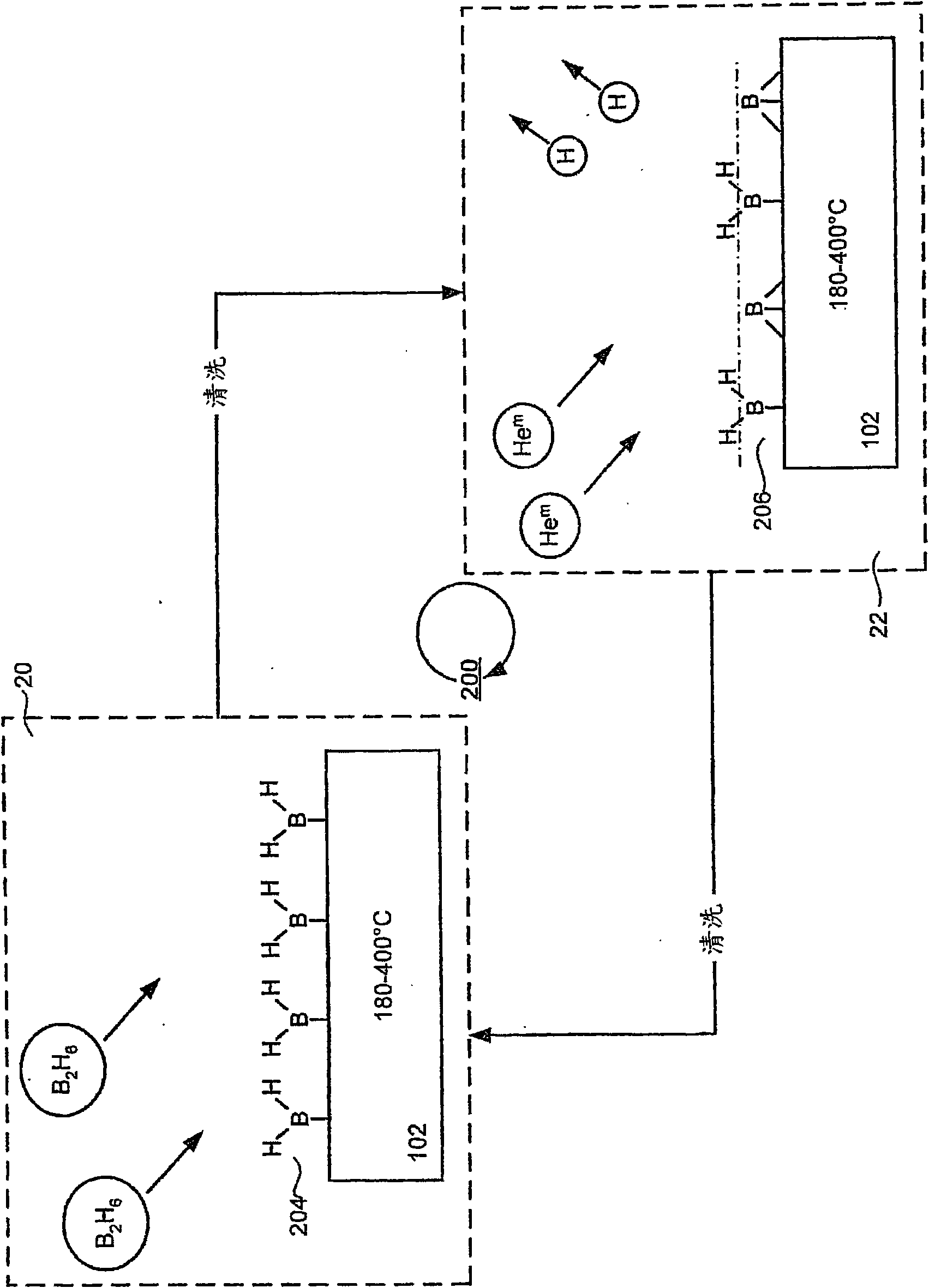

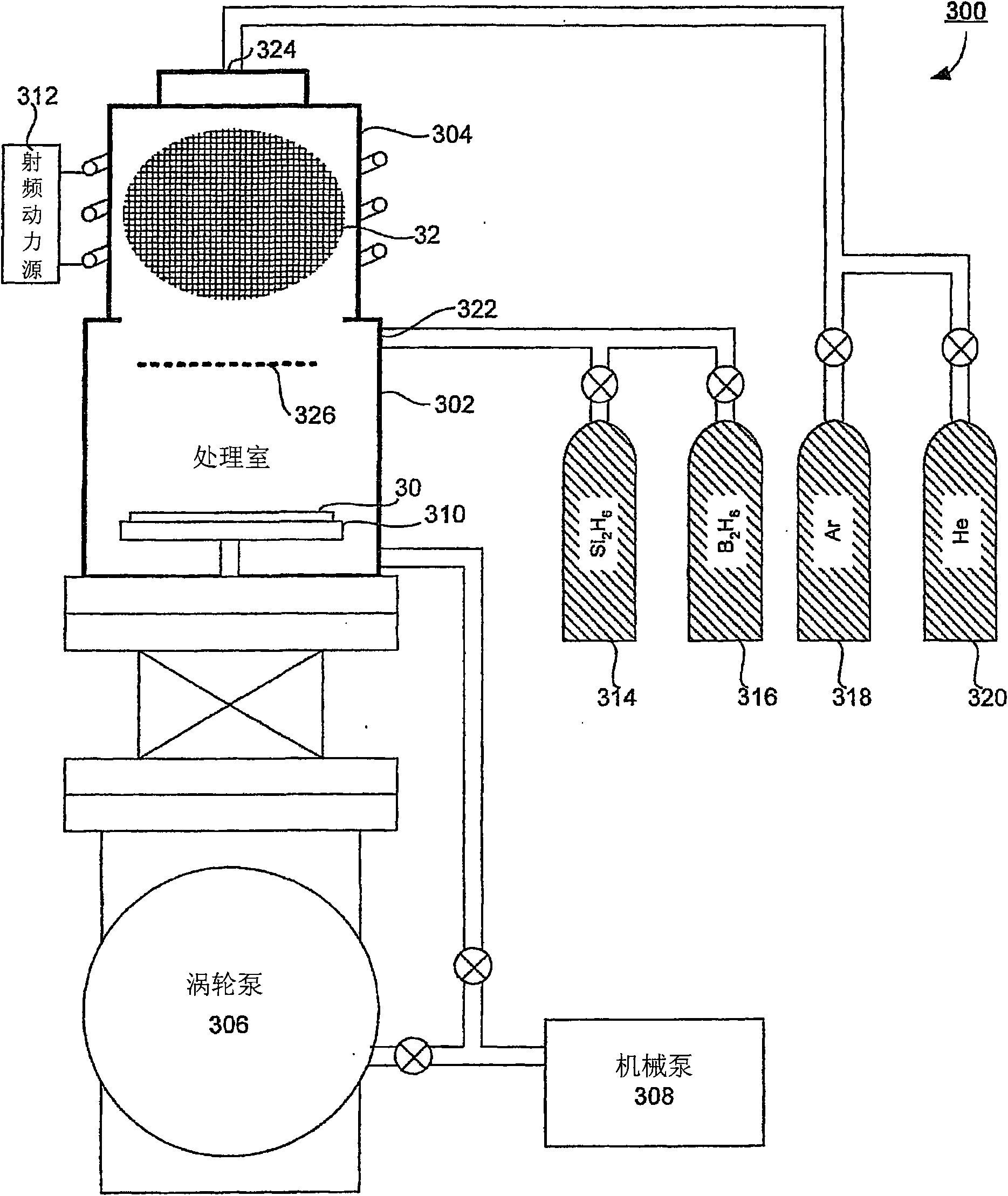

[0017] In order to solve the above-mentioned technical problems related to the existing atomic layer deposition technology, embodiments of the present invention introduce ALD and in situ doping technology. Use metastable atoms to desorb excess atoms. For example, metastable atoms are generated within the plasma chamber. For purposes of illustration, the ensuing description will focus on methods and apparatus for depositing doped or undoped silicon using helium metastable atoms. It will be appreciated that films of other species can also be grown using the same or similar techniques using helium or other metastable atoms.

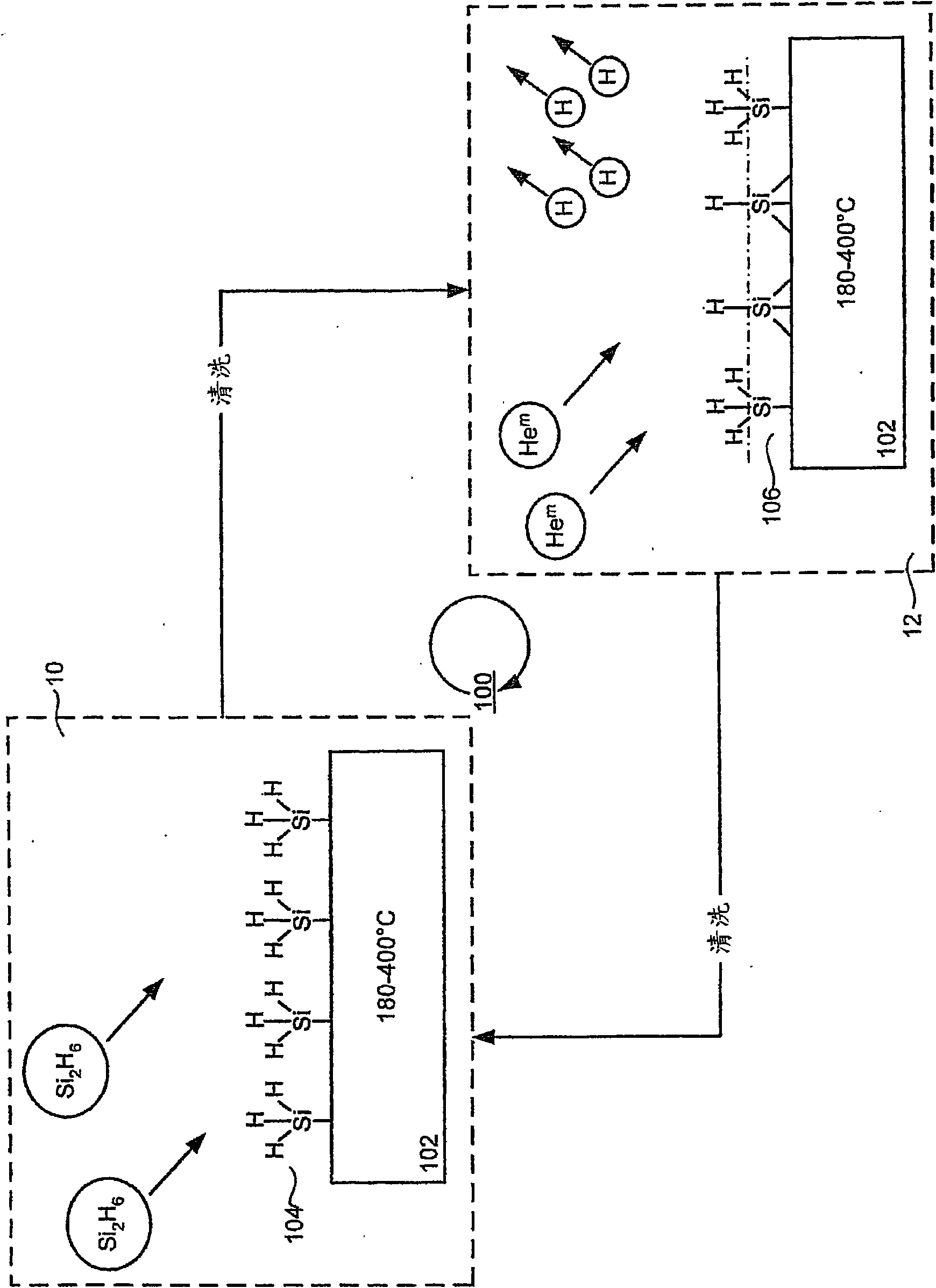

[0018] refer to figure 1 , which shows a schematic block diagram of an atomic layer deposition cycle 100 according to an embodiment of the present invention. The atomic layer deposition cycle 100 includes two phases, a saturation phase 10 and a desorption phase 12 .

[0019] In the saturation phase 10, the substrate 102 is exposed to disilane (Si2H6) gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com