Tobacco leaf and green mould proof method of products thereof

A tobacco leaf and mildew-proof technology, which is applied in the fields of tobacco, tobacco processing, and application, can solve the problems of immovability and low irradiation efficiency, cumbersome operation process of the sealed oxygen reduction method, consuming a lot of manpower, material resources and time, etc. The effect of automation, improving suction quality, and reducing management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

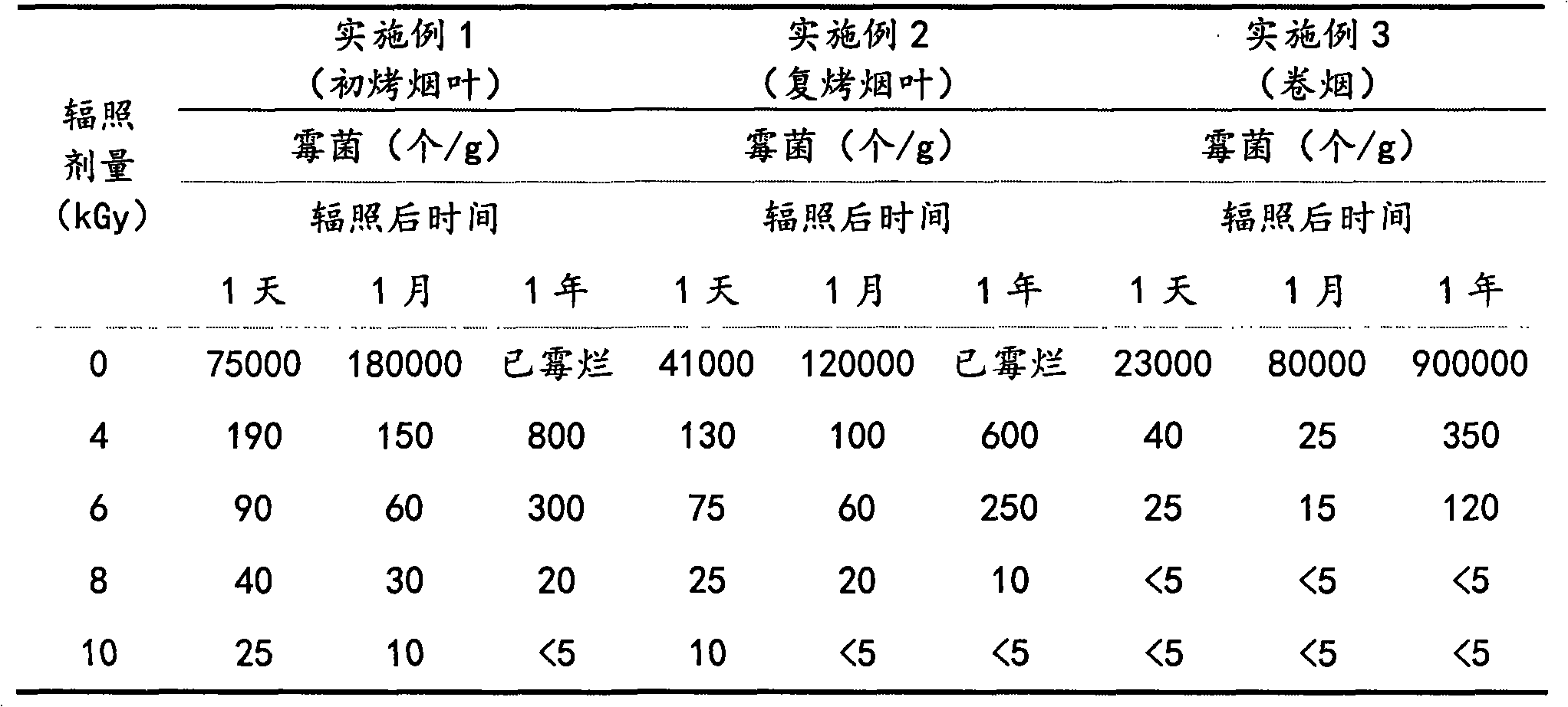

[0017] Randomly take 300kg of first-cured tobacco leaves, pack each 30kg into a box, a total of 10 boxes, seal and pack them in corrugated boxes with plastic film lining, and then use electron beams at doses of 0kGy, 4kGy, 6kGy, 8kGy, and 10kGy for irradiation treatment , 2 boxes for each treatment, stored in a warehouse with a temperature of 25°C-30°C and a relative humidity of 75%-95% after irradiation, and regularly sampled for microbial testing. The test results are shown in Table 1. After each sampling, the packaging is still sealed Best stored under original conditions.

Embodiment 2

[0019] Randomly take 400kg of re-cured tobacco leaves, pack each 40kg into a box, a total of 10 boxes, seal and pack them in corrugated boxes with plastic film lining, and then use electron beams of 0kGy, 4kGy, 6kGy, 8kGy, and 10kGy for irradiation treatment , 2 boxes for each treatment, stored in a warehouse with a temperature of 25°C-30°C and a relative humidity of 75%-95% after irradiation, and regularly sampled for microbial testing. The test results are shown in Table 1. After each sampling, the packaging is still sealed Best stored under original conditions.

Embodiment 3

[0021] 10 boxes of cigarettes of the same brand that had just been purchased from the cigarette factory were irradiated with X-rays of 0kGy, 4kGy, 6kGy, 8kGy, and 10kGy respectively. ℃, relative humidity of 75%-95% of the warehouse, regular sampling for microbial testing, the test results are shown in Table 1, after each sampling, still sealed and packaged for storage under the original conditions.

[0022] Table 1 Anti-mold effect of tobacco leaf irradiation

[0023]

[0024] Determination method of mold in Table 1: according to GB / T4789.15 "Food Hygiene Microbiological Examination of Mold and Yeast Count".

[0025] As can be seen from Table 1, the radiation-proof mildew-proof method for tobacco leaves and products thereof of the present invention has a remarkable anti-mold effect by killing enzymes. Compared with unirradiated samples, 4kGy-10kGy dose irradiation treatment can reduce the number of molds by orders of magnitude, 8kGy-10kGy dose irradiation treatment samples...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com