Ball dropper used for drop ball forming of oxide

A technology of oxide and ball dropper, which is applied in the direction of chemical instruments and methods, chemical/physical processes, liquid separation into beads and granulation, etc. It can solve the inconvenience of disassembly and cleaning, sticking of drippers, uneven particle size of formed products, etc. problems, to achieve the effect of regular shape and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

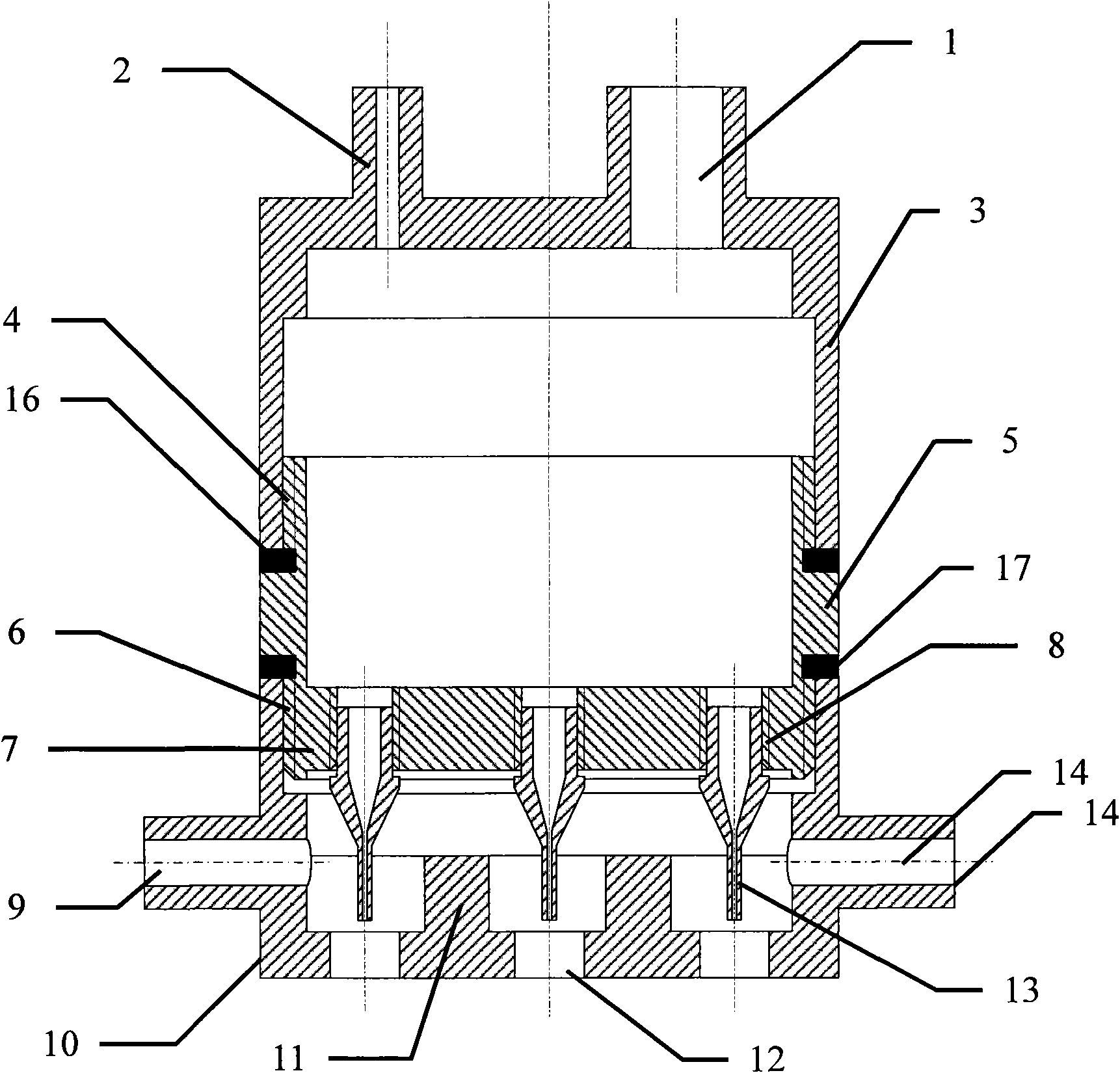

[0034] Alumina pellets are produced by adopting the dropping ball device provided by the invention and the oil ammonia column forming method.

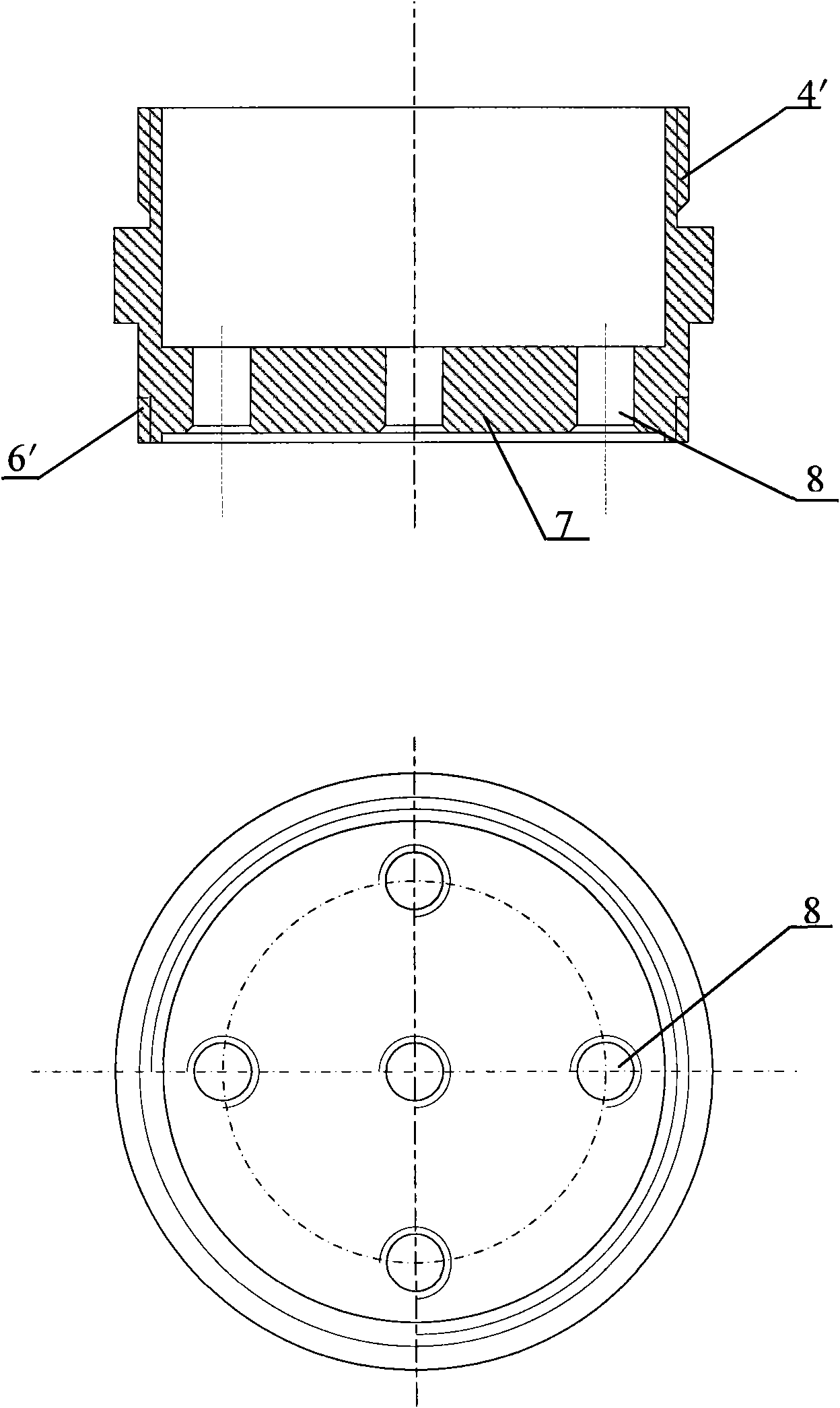

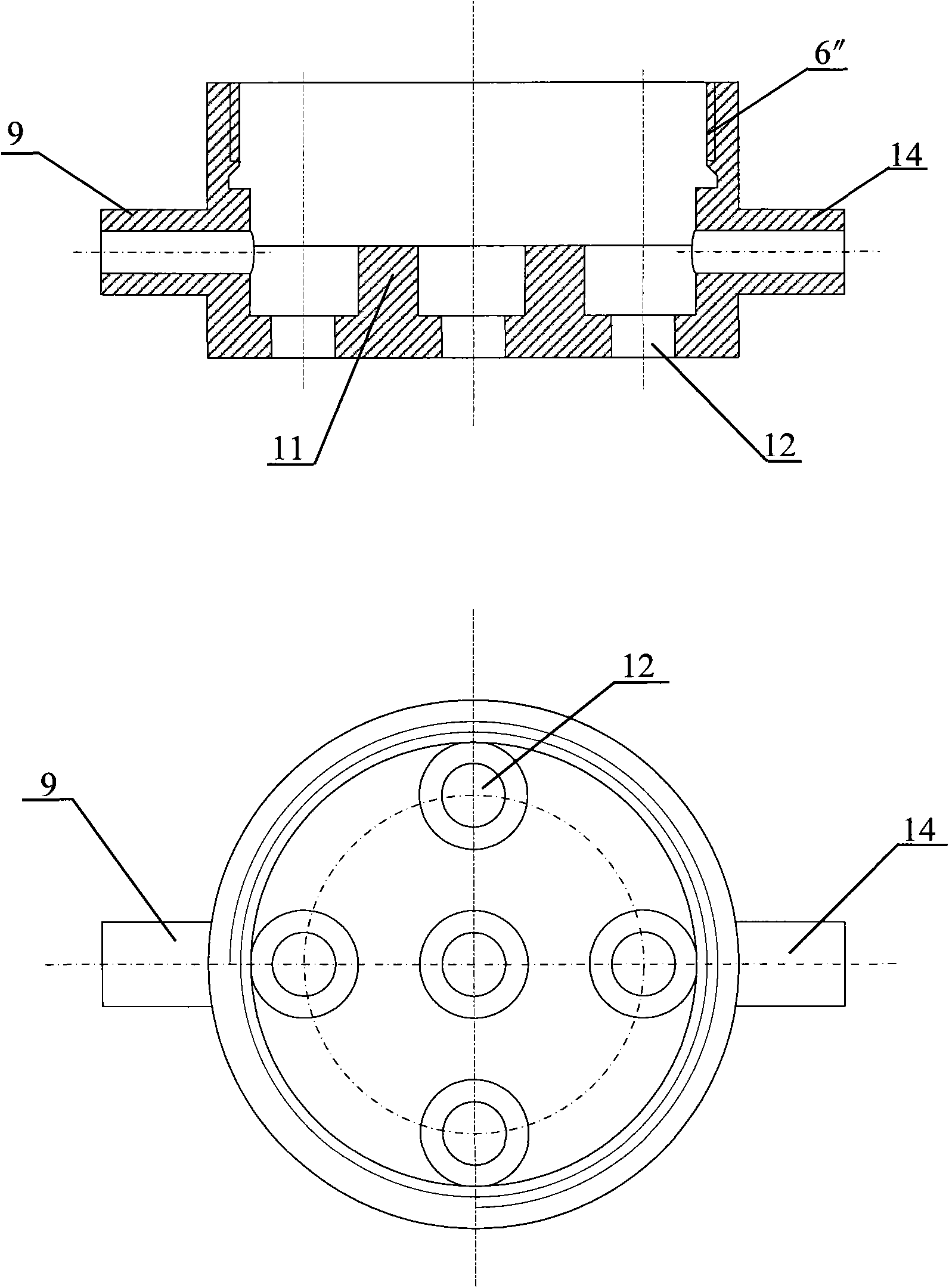

[0035] use the present invention figure 1 The drip bulb shown in the figure, but 10 dripper sockets are evenly arranged on the bottom plate of the lower housing of the dripper, and 10 drippers are installed, and the distance between the drippers is 25 mm. The gas disturbance plate is installed on the bottom plate of the jacket of the ball dropper, and the angle α between them is 120°. The diameter of the dropper of the dripper is 1 mm, and there are 10 vents with a diameter of 30 mm on the bottom plate of the dripper jacket. Each vent corresponds to a dripper and is coaxial with the dripper.

[0036] The oily ammonia column is 1.5 meters high and 7 centimeters in column diameter, n-heptane is the oil phase, its viscosity is 0.41 centipoise, the oil layer is 2 millimeters high, and 8 mass % ammonia water is the water phase with a heigh...

example 2

[0041] The zirconia-silicon oxide pellets are produced by adopting the dropping ball device provided by the invention and the oil ammonia column forming method.

[0042] use Figure 5 The difference in the drip bulb shown is that 200 drippers are installed on the bottom plate of the lower housing of the drip bulb, and the 200 drippers are evenly distributed on the bottom plate of the lower housing of the drip bulb, and the distance between the drippers is 30 mm. There are 210 ventilation openings with a diameter of 35 mm on the bottom plate of the dropper jacket, of which 200 ventilation openings correspond to a dripper and are coaxial with the dripper. The gas turbulence components on the base plate are gas pipelines with gas outlets distributed in the air vents in the jacket. The drip-tip has a diameter of 2 mm and protrudes 2 mm from the bottom of the bulb lower housing.

[0043] Continuously produce zirconia-silica pellets with zirconium hydroxide colloid and silica sol ...

example 3

[0049] Adopt the dripping ball device of example 2 and the oleyl ammonia column to produce ZSM-5-alumina pellets. The difference is that the bottom of the drop ball device is 10 cm away from the oil surface.

[0050] The ZSM-5-alumina pellets are continuously produced from the mixture of aluminum hydroxide colloid and ZSM-5 powder. The solid content of aluminum hydroxide colloid in the raw material is 30% by mass, the silicon oxide / alumina molar ratio of the ZSM-5 powder is 60, and the mass of aluminum hydroxide and ZSM-5 is 1:1.

[0051] Drop rate is 20 drops / cm 2 ·minute. The protective gas in the jacket of the dropper is air, the flow rate is 30 ml / min, and the pressure is 0.12 MPa.

[0052] The raw material slurry and air intermittently enter the shell of the ball dropper. After the particles of the raw material slurry drop out, they form balls in the oil phase of the oil ammonia column. The balls pass through the oil-ammonia water interface smoothly, enter the ammonia ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com