Decorative brick and preparation method thereof

A technology for decorative bricks and cement, which is applied in the manufacture of tools, ceramic molding machines, construction, etc., and can solve problems such as complex process, high cost, and difficult operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

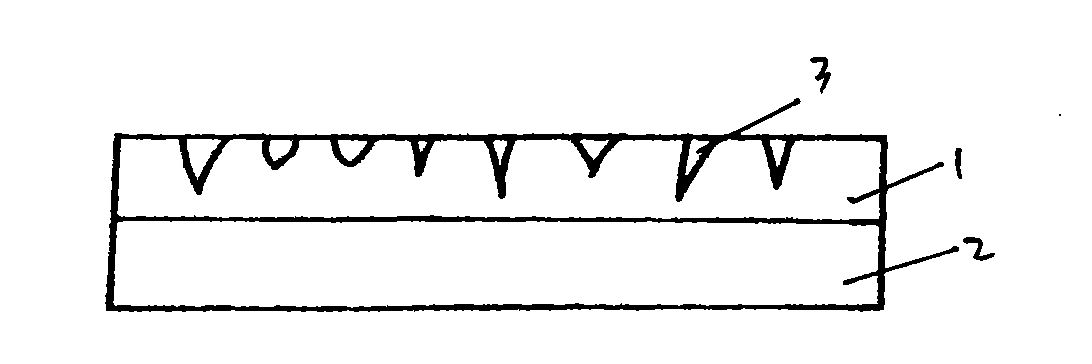

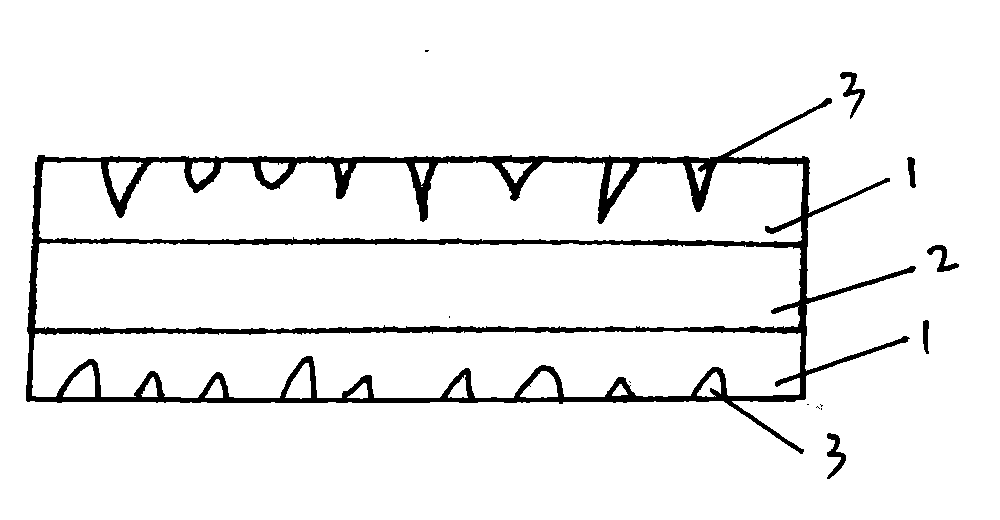

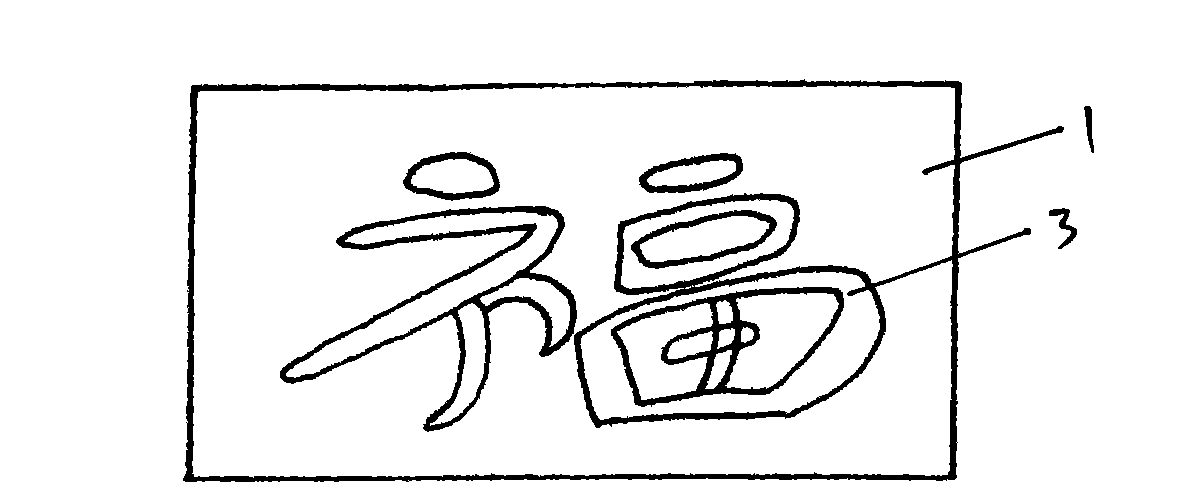

[0025] The preparation method of the decorative brick of the present invention is to take the bottom layer raw materials in proportion and mix them well, pour them into the bottom layer of the mould, then take the surface layer raw materials in proportion to fully mix them and pour them into the upper layer of the mould, and send the filled mold into a mold with Surface three-dimensional embossing is performed on the hydraulic press of the three-dimensional pattern top mold, and the mold is instantly shaped and demoulded, and then solidified at room temperature or under heating to obtain a product with a three-dimensional pattern (concave-convex three-dimensional pattern) on one side of the surface. The thickness of the product is about 1.5cm, such as figure 1 .

[0026] The weight ratio of lower layer cement, river sand, stone and water described in this example is 25:50:10:8. The size of the stones ranges from 0.3 to 10 cm.

[0027] The weight ratio of upper cement, fine st...

Embodiment 2

[0029] The preparation method of the decorative brick of the present invention is to take the bottom layer raw materials in proportion and mix them well, pour them into the bottom layer of the mould, then take the surface layer raw materials in proportion to fully mix them and pour them into the upper layer of the mould, and send the filled mold into a mold with Three-dimensional embossing on the surface of the three-dimensional pattern top mold is carried out on the hydraulic press, and the mold is instantly shaped and demoulded, and then solidified at room temperature or under heating to obtain a product with a three-dimensional pattern (concave-convex three-dimensional pattern) on one side of the surface. The thickness of the product is about 1.6cm, and the pattern of the three-dimensional pattern The depth is about 0.3-0.5cm. Such as figure 1 .

[0030] The weight ratio of lower layer cement, river sand, stone and water described in this example is 30:60:15:10. The size ...

Embodiment 3

[0034] The preparation method of the decorative brick of the present invention is to take the bottom layer raw materials in proportion and fully mix them, pour them into the bottom layer of the mould, then take the surface layer raw materials in proportion to fully mix them and pour them into the upper layer of the mould, and send the filled mold into a mold with Surface three-dimensional embossing is performed on the hydraulic press of the three-dimensional pattern top mold, and the mold is instantly shaped and demoulded, and then solidified at room temperature or under heating to obtain a product with a three-dimensional pattern (concave-convex three-dimensional pattern) on one side of the surface. The thickness of the product is about 2cm, such as figure 1 .

[0035] The weight ratio of lower layer cement, river sand, stone and water described in this example is 35:65:18:9. The size of the stone is preferably ranging from 0.3 to 10 cm. The river sand described in this exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Pattern depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com