Perforated glass plate and structure using same

A glass plate and support structure technology, applied in building components, building structures, building insulation materials, etc., can solve the problems of high wind safety impact, lack of ventilation, noise and other problems of glass plates, and achieve the effect of ensuring indoor air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

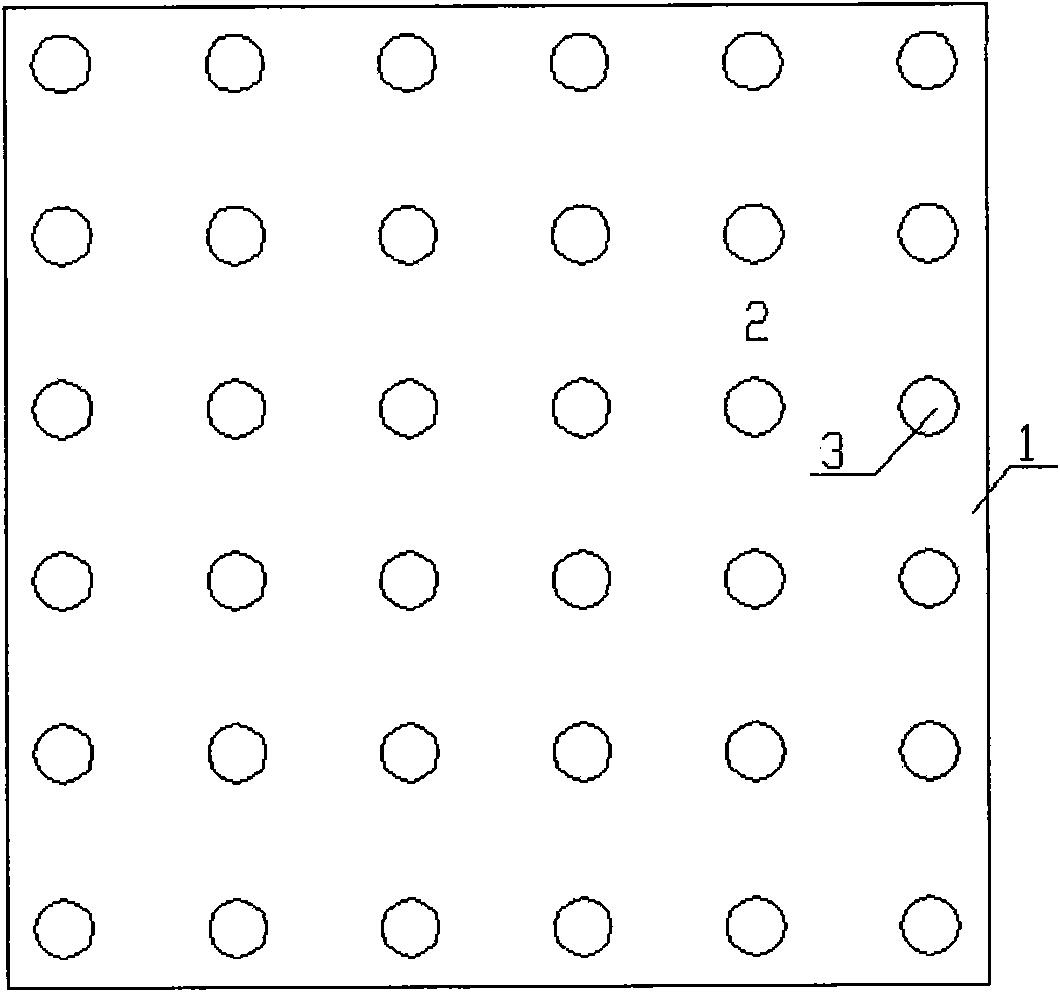

[0051] see Figure 1a , figure 2 , the perforated glass plate 1 is provided with small holes 3, and the small holes 3 run through in the thickness direction and are regularly distributed in the plane direction; , ≥0.5%, ≤30%, preferably ≥5%, ≤20%. The thickness of the porous glass plate 1 is ≥2 mm and ≤100 mm; the small hole 3 is circular, with a diameter of ≥0.1 mm and ≤500 mm, preferably ≥1 mm and ≤100 mm.

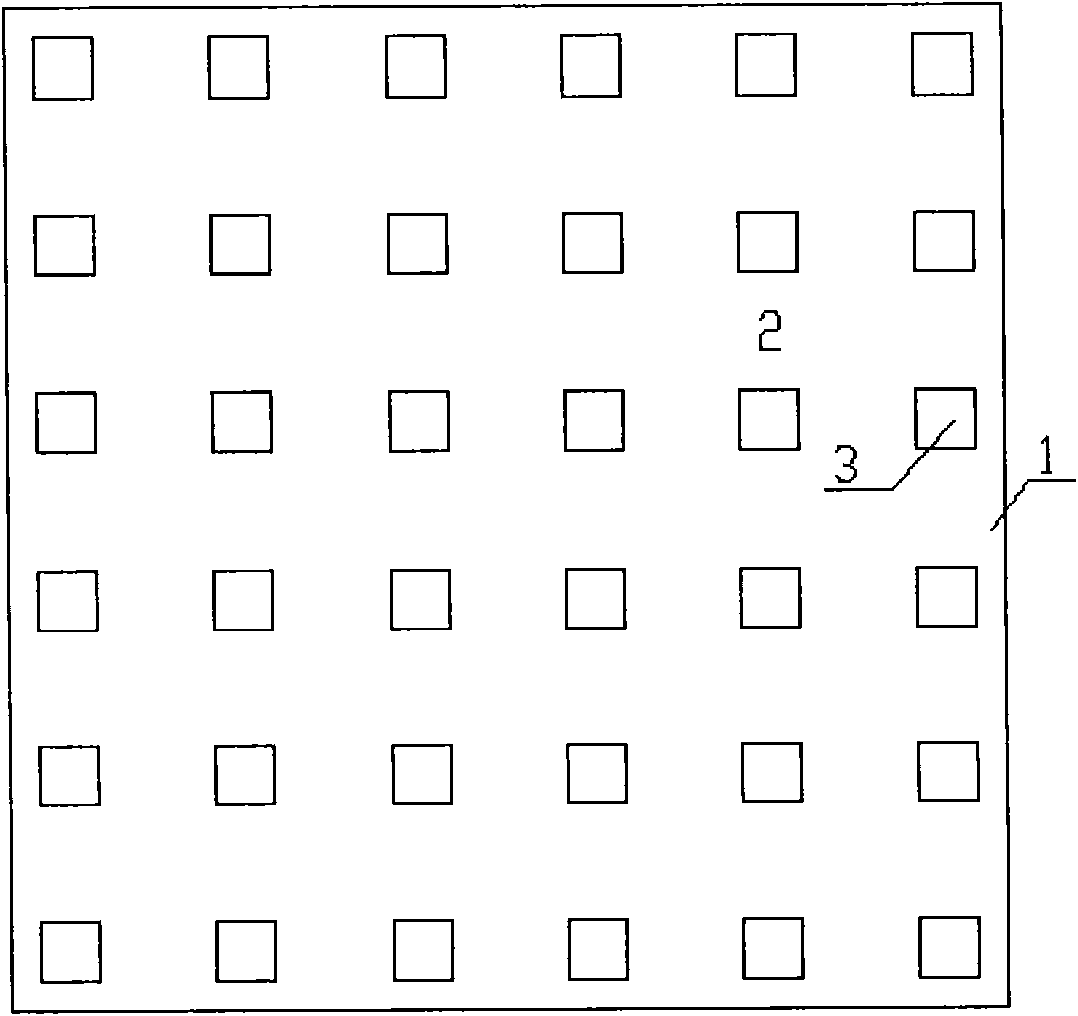

[0052] see Figure 1b , figure 2 , the perforated glass plate 1 is provided with small holes 3, and the small holes 3 run through in the thickness direction and are regularly distributed in the plane direction; , ≥0.5%, ≤30%, preferably ≥5%, ≤20%. The thickness of the porous glass plate 1 is ≥2 mm and ≤100 mm; the small hole 3 is polygonal, and the diameter of the circumscribed circle is ≥0.1 mm and ≤500 mm, preferably ≥1 mm and ≤100 mm.

Embodiment 1

[0053] Embodiment one: form one of the window of the building structure that adopts the perforated glass plate

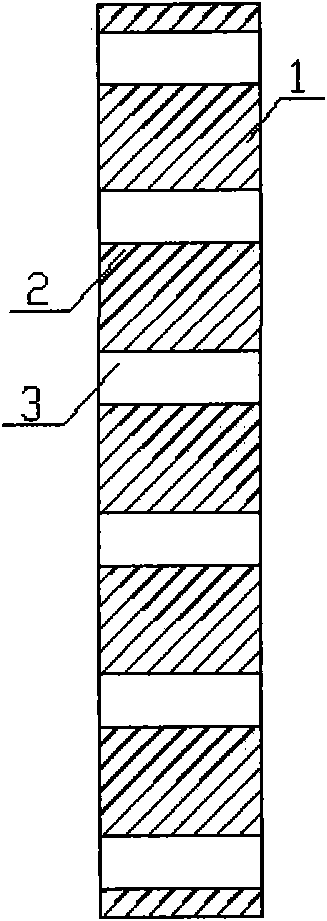

[0054] see image 3 The window of the building structure (including glass curtain wall) is formed by the combination of perforated glass plate 1, ordinary glass plate 4 and support structure 12, and there is a gap 5 of 1 mm to 500 mm between the perforated glass plate 1 and ordinary glass plate 4; Plate 4 adopts prior art single-layer glass plates such as float glass, tempered glass, tempered glass for curtain wall and semi-tempered glass for curtain wall. The support structure 12 adopts a frame, a frame, and can also adopt ribbed glass, metal support structure points, etc. (not shown in the figure). The perforated glass plate 1 is installed on the indoor side 6, and the common glass plate 4 is installed on the outdoor side 7, and of course it can also be set in reverse. When ventilation is required, the ordinary glass plate 4 is opened, the perforated glass plate...

Embodiment 2

[0055] Embodiment two: adopt the form two of building window of perforated glass plate

[0056] see Figure 4 The window of the building structure (including the glass curtain wall) is formed by the combination of the porous glass plate 1, the insulating glass 8 and the supporting structure 12, and there is a gap 5 of 1 mm to 500 mm between the porous glass plate 1 and the insulating glass 8; the supporting structure 12 adopts Frames, frames, ribbed glass, metal support structure points, etc. (not shown in the figure) can also be used. The perforated glass plate 1 is installed on the indoor side 6, and the common glass plate 4 is installed on the outdoor side 7, and of course it can also be set in reverse. When ventilation is required, the hollow glass 8 is opened, the perforated glass plate 1 is in a closed state, and the air passes in and out through the small holes 3 on the perforated glass plate 1 to realize indoor and outdoor air circulation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com