Heat radiation device of heat pipe of loop of temperature-equalization tank with high heat conductivity

A technology of loop heat pipe and heat dissipation device, which is applied to the cooling/heating device, lighting device, indirect heat exchanger, etc. of lighting device, can solve the problems of difficult to balance the temperature at the heat source, affecting the conduction of heat, and the existence of voids, etc. Achieve the effect of improving LED luminous efficiency, prolonging service life and fast heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

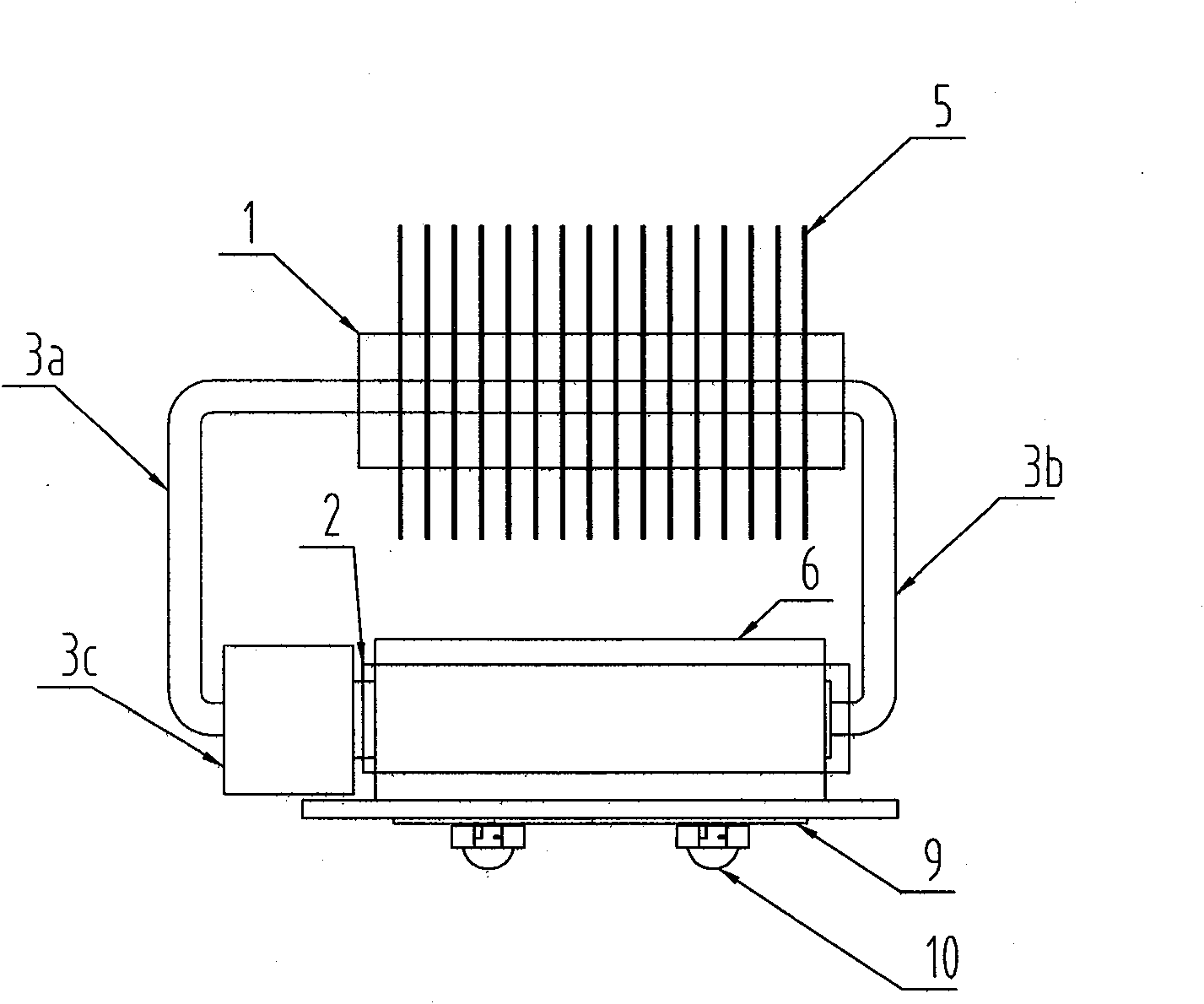

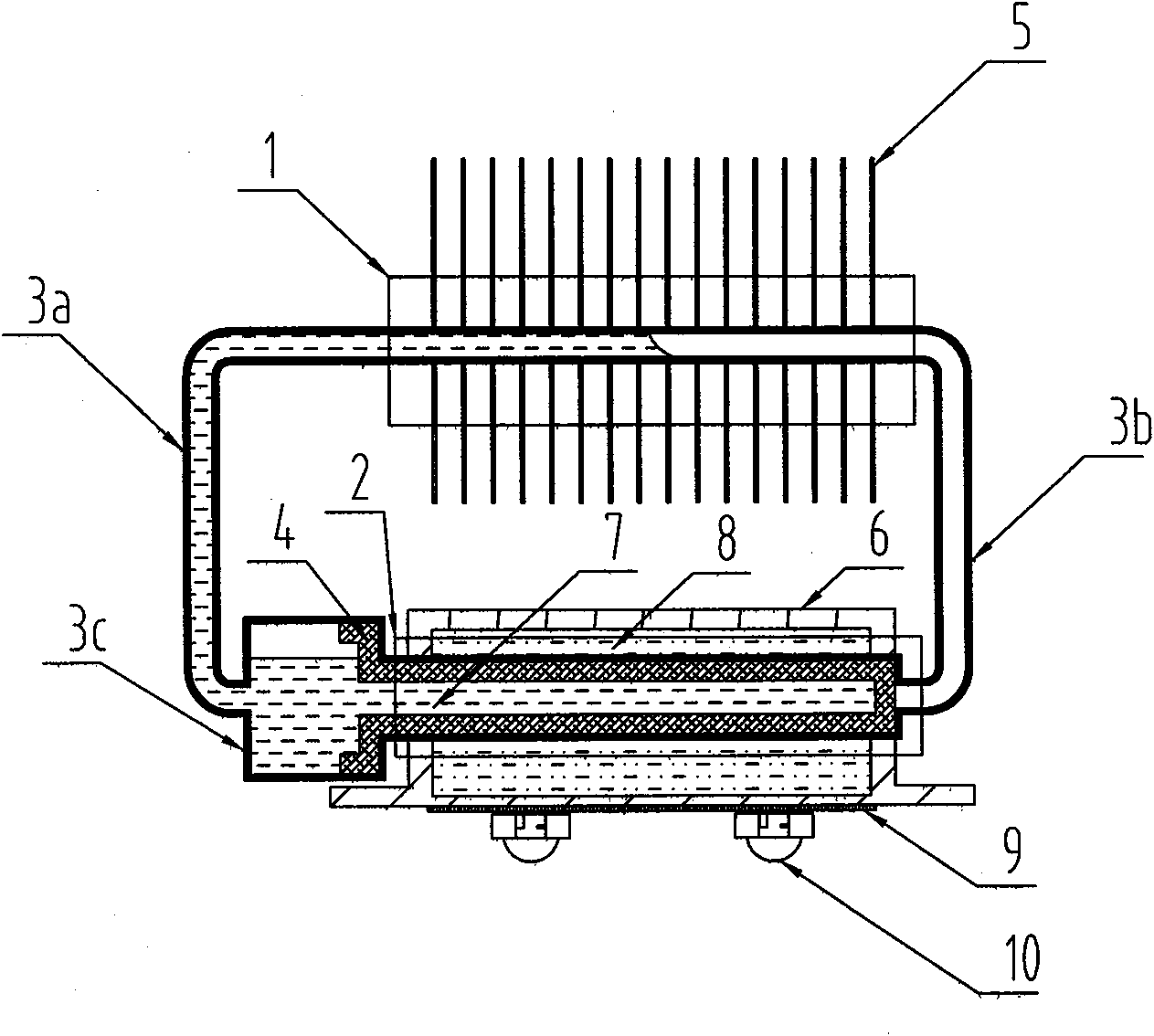

[0017] Such as figure 1 , figure 2 As shown, the high thermal conductivity soaking box loop heat pipe cooling device for heat dissipation of LED lamps is composed of heat pipes, heat sinks 5, high thermal conductivity soaking box 6, and high thermal conductivity liquid 8. The cross-sectional shape of the high thermal conductivity soaking box 6 is square, rectangular or circular, and the material of the high thermal conductivity soaking box is a metal material with high thermal conductivity, which is arranged on the back of the heat source surface (the LED circuit substrate 9 and the LED light source 10 of the LED lamp) . The heat pipe is a primary loop circulation pipe, which is divided into an evaporation section 2, a return section 3a, a steam section 3b, a compensation chamber 3c, and a condensation section 1. The evaporating section 2 passes through the high thermal conductivity soaking box 6 and is connected into one body by welding. A sealed cavity is formed between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com