Coating capable of reducing use loss of platinum bushings and preparation method thereof

A bushing and coating technology, which is applied in the field of coating and its preparation to reduce the use loss of platinum bushings, can solve the problems of increased platinum volatilization loss, and achieve the effects of reducing use loss and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

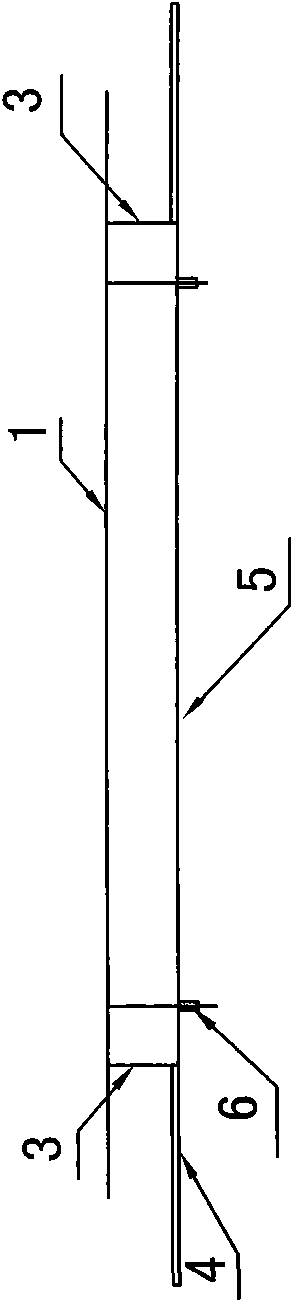

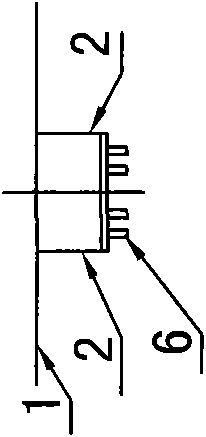

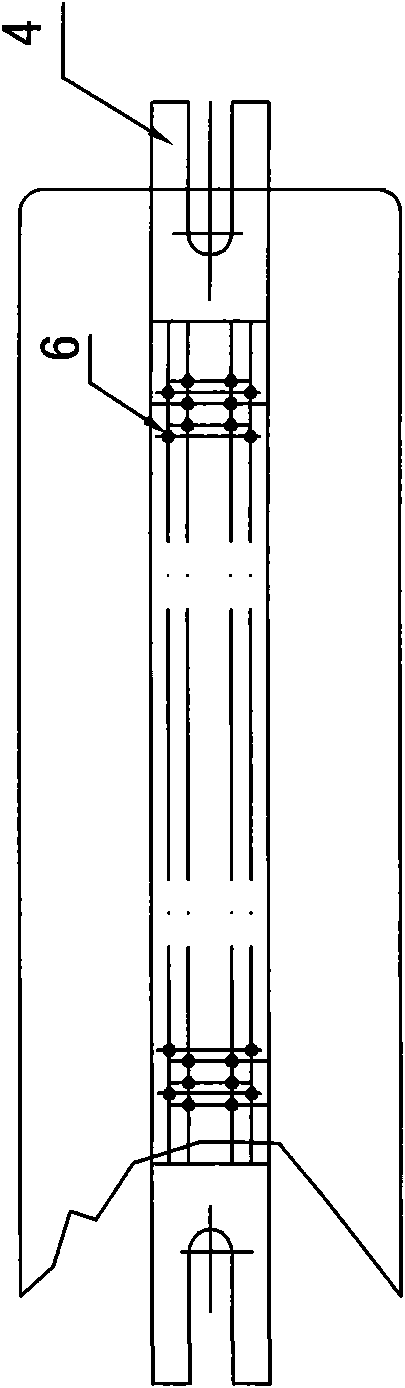

[0021] The bushing plate shown in the figure is a known structure.

[0022] The present invention reduces the coating preparation and preparation and installation method of platinum bushing plate as follows:

[0023] 1. Coating powder 150±10g, Suzhou soil 10±2g, distilled water 150ml-170ml

[0024] Stir the weighed coating powder, Suzhou soil and distilled water in a ceramic container to form a uniform and relatively thin coating, and let it stand for 24 hours before use.

[0025] 2. Coating powder 150±10g, Suzhou soil 10±2g, distilled water 120ml-140ml

[0026] The weighed coating powder, Suzhou soil and distilled water are stirred in a ceramic container to form a uniform and relatively viscous coating, which is left to stand for 24 hours before use.

[0027] 3. Soak the polished tumbler in water for more than 8 hours and set aside.

[0028] 4. To clean the leakage board, clean and dry the leakage board with alcohol.

[0029] 5. For the leak board coating, evenly apply th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com