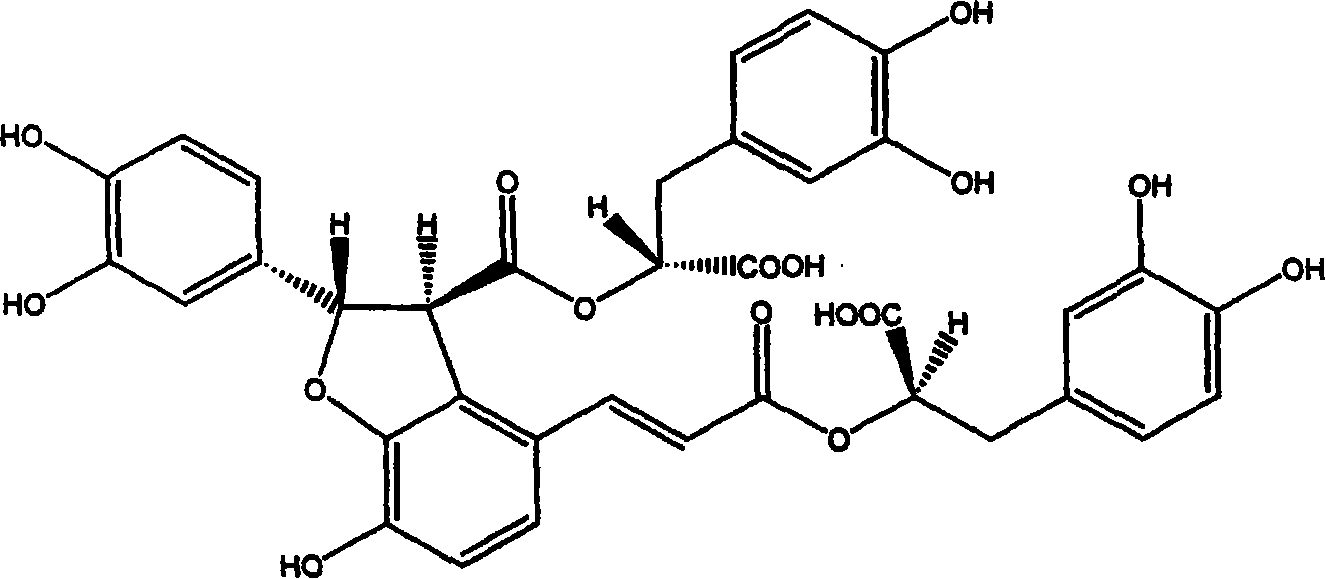

High-purity salvianolic acid B and preparation method and application thereof

A salvianolic acid, high-purity technology, applied in the field of high-purity salvianolic acid B, preparation and application, can solve the problems of unsuitable industrial production, low purity of salvianolic acid B, and many steps, and achieve low cost and low price , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take 1000g of Salvia miltiorrhiza, grind it, add deionized water, heat and extract at 100°C for 1 hour, use water 5 times the weight of Salvia miltiorrhiza, and decoct and extract twice under the condition of pH 4.8, 40 minutes each time, use the weight of Danshen 3 times water. The extract was filtered, the pH was adjusted to 3, and the DA-201 polar resin was used for chromatography, and the impurities were eluted with water, and then 10% ethanol was used for removal of impurities, and 80% ethanol was used for desorption. The components containing salvianolic acid B were collected and recovered under reduced pressure. The resulting solution was then chromatographed on a polyamide column and desorbed with 95% ethanol to obtain components containing salvianolic acid B. The fractions with a purity greater than 98.5% were collected in sections, concentrated under reduced pressure, and adjusted to pH 4.8. The concentrated solution is passed through a Sephadex column, and t...

Embodiment 2

[0034] Take 1500g of Salvia miltiorrhiza, grind it, add deionized water, heat and extract at 100°C for 1 hour, use 5 times of water, then decoct and extract 3 times under the condition of pH4.8, each time for 40 minutes, use 3 times of water . The extract was filtered, the pH was adjusted to 2, and the DA-201 polar resin was used for chromatography, and the impurities were eluted with water, and then 20% ethanol was used for removal of impurities, and 90% ethanol was used for desorption. The components containing salvianolic acid B were collected and recovered under reduced pressure. The resulting solution was then chromatographed on a polyamide column and desorbed with 90% ethanol to obtain components containing salvianolic acid B. The fractions with a purity greater than 98% were collected in sections, concentrated under reduced pressure, and adjusted to pH 5. The concentrated solution is passed through a Sephadex column, and the parts with a purity greater than 98.5% are c...

Embodiment 3

[0036] Take 2000g of Salvia miltiorrhiza, grind it, add deionized water, heat and extract at 100°C for 1 hour, use 5 times the water, and then decoct and extract twice under the condition of pH4.8, each time for 40 minutes, use 3 times of water. Filter the extract, adjust the pH to 4, use DA-201 polar resin chromatography, elute with water to remove impurities, then remove impurities with 10% ethanol, desorb with 95% ethanol, and collect the group containing salvianolic acid B Separate, and recover ethanol under reduced pressure. The obtained product is then chromatographed on a polyamide column, desorbed with 95% ethanol, and the parts with a purity greater than 98% are collected in sections, concentrated under reduced pressure, and adjusted to pH 4.8. The concentrated solution is passed through a Sephadex column, and the parts with a purity greater than 98.5% are collected in sections, concentrated under reduced pressure, and freeze-dried to obtain high-purity salvianolic ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com