Novel low-cost single bar liquid refrigeration laser and manufacturing method thereof

A cost-effective laser technology, applied to semiconductor lasers, structural details of semiconductor lasers, lasers, etc., can solve problems such as spectral broadening, blockage, and large flow resistance of cooling media, so as to increase heat dissipation area, reduce manufacturing costs, and improve The effect of cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in further detail below in conjunction with accompanying drawing:

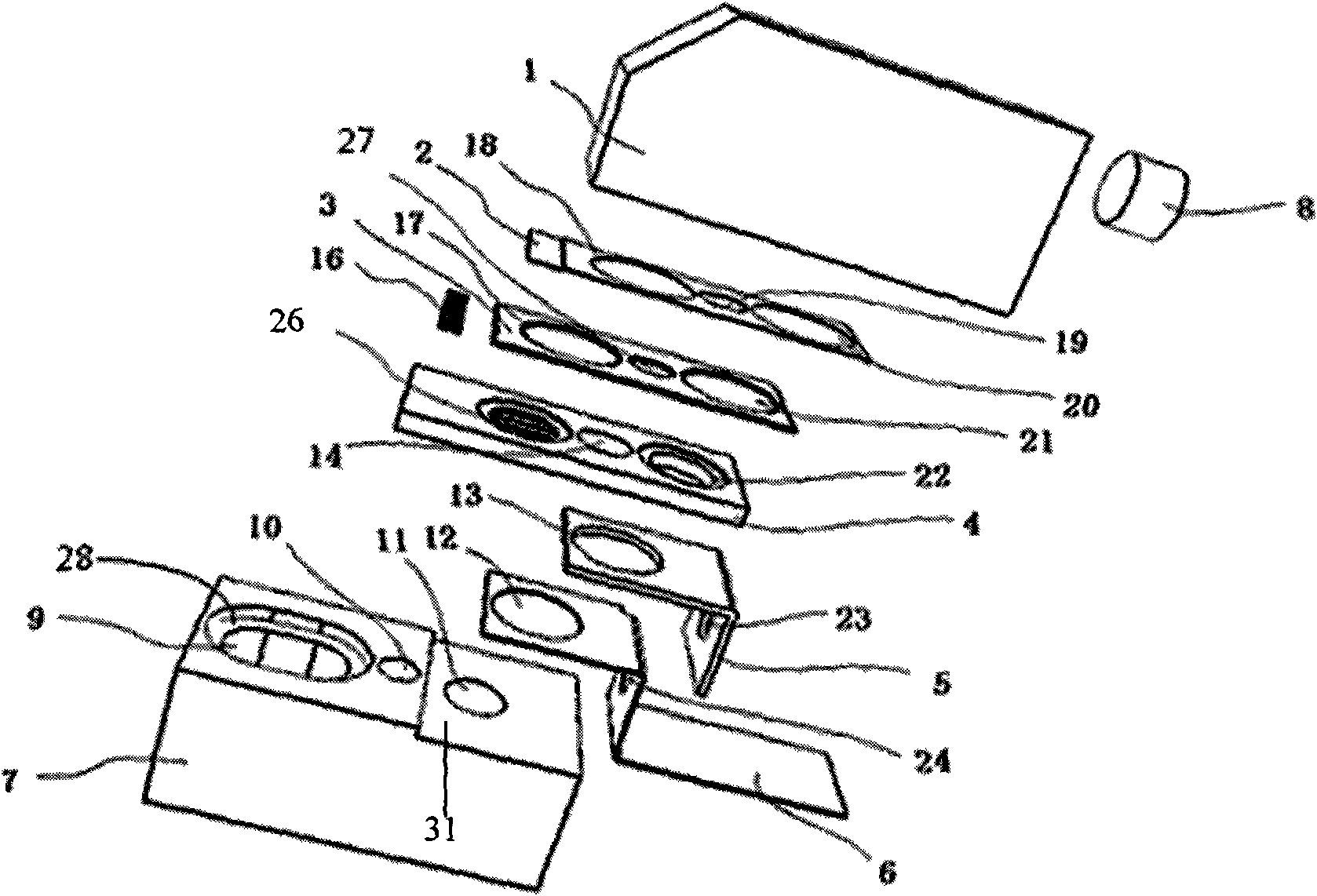

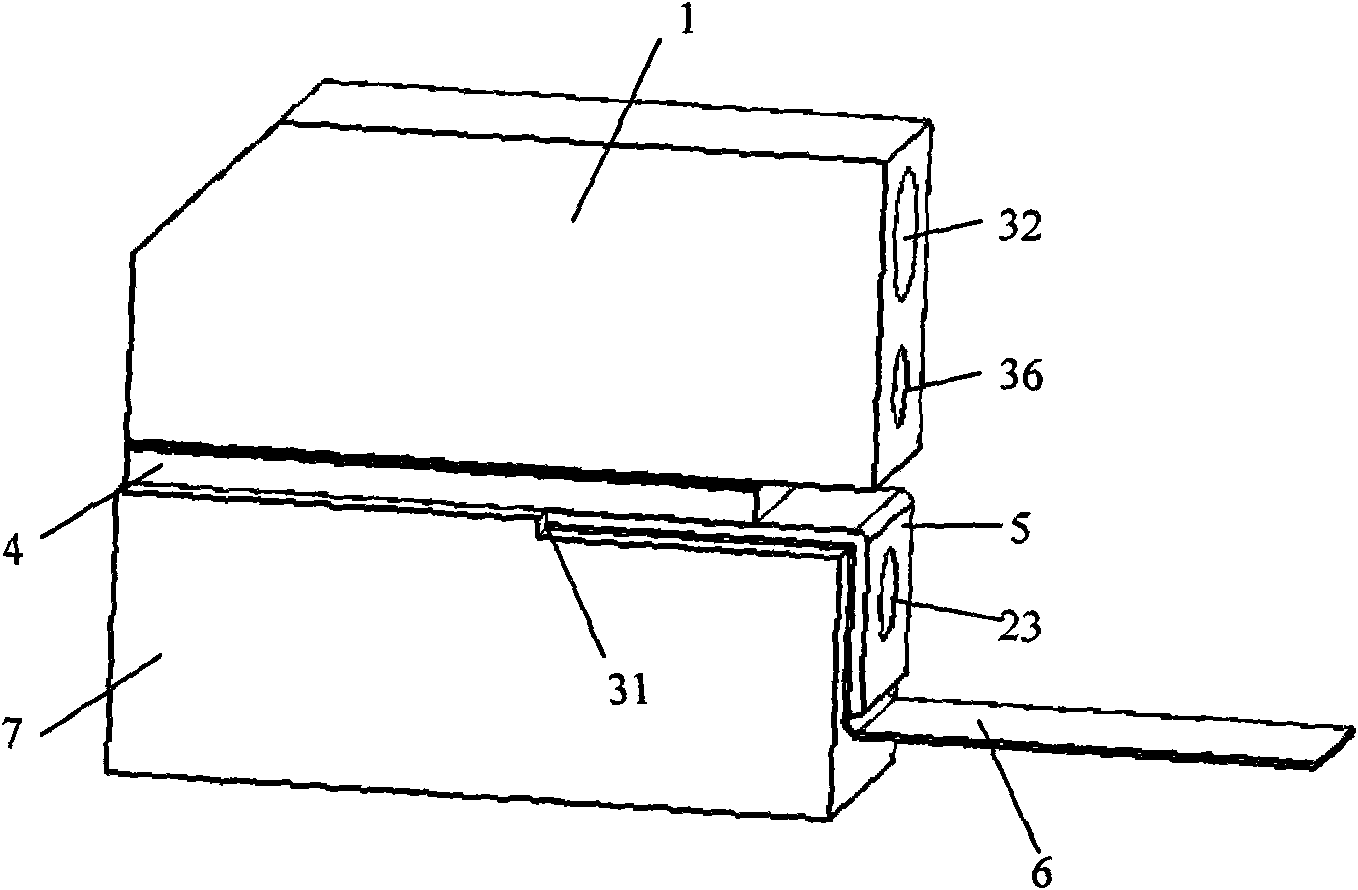

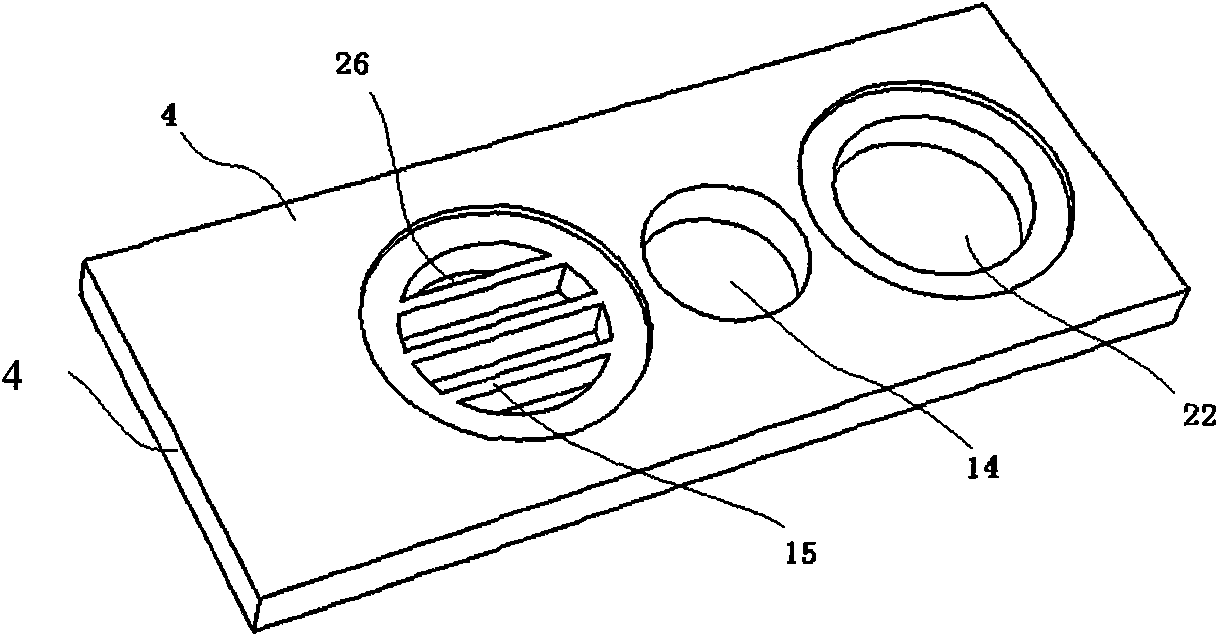

[0040] see figure 1 , figure 2 , Figure 4 and Figure 5, the novel low-cost single-bar liquid-cooled laser of the present invention comprises an upper liquid refrigeration block 1 (negative electrode block), negative electrode connecting piece 2, insulating sheet 3, positive electrode connecting piece 6, connecting piece fixing piece 5, micro positive electrode block 4 and Lower liquid refrigeration block 7. The lower liquid refrigeration block 7, the micro positive electrode block 4, the insulating sheet 3, the negative electrode connection sheet 2 and the upper liquid refrigeration block 1 are sequentially stacked and connected together from bottom to top. One side of the upper end surface of the lower liquid refrigeration block 7 is provided with a step 31, and the positive connection piece 6 and the connection piece fixing piece 5 are arranged on the step 31;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com