Vegetarian microcapsules

A technology of microcapsules and primary shells, applied in the field of preparation and use of such microcapsules, can solve problems such as incompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

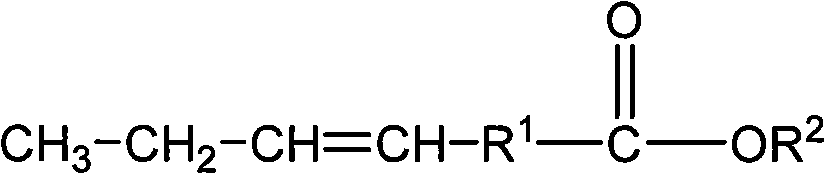

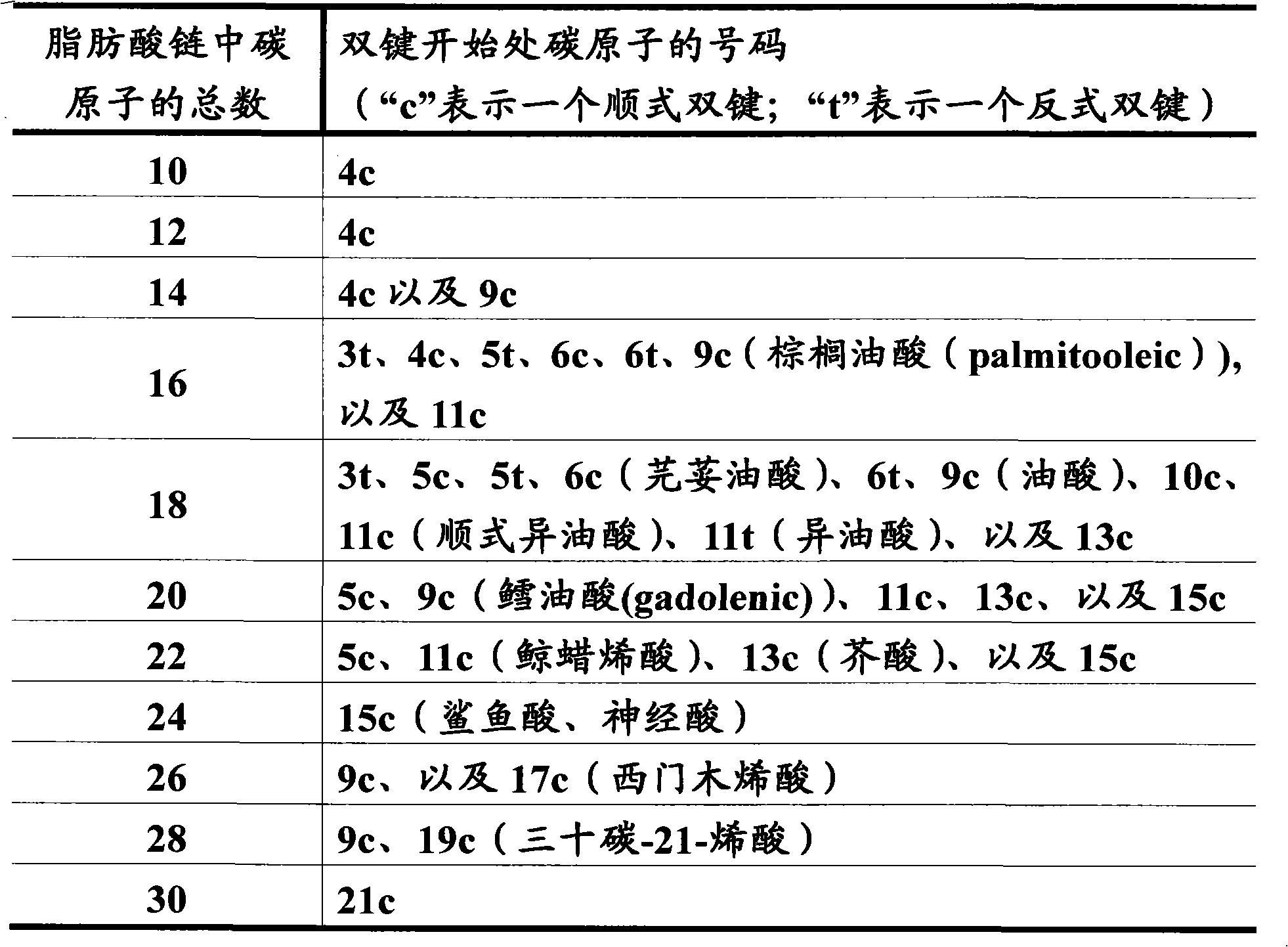

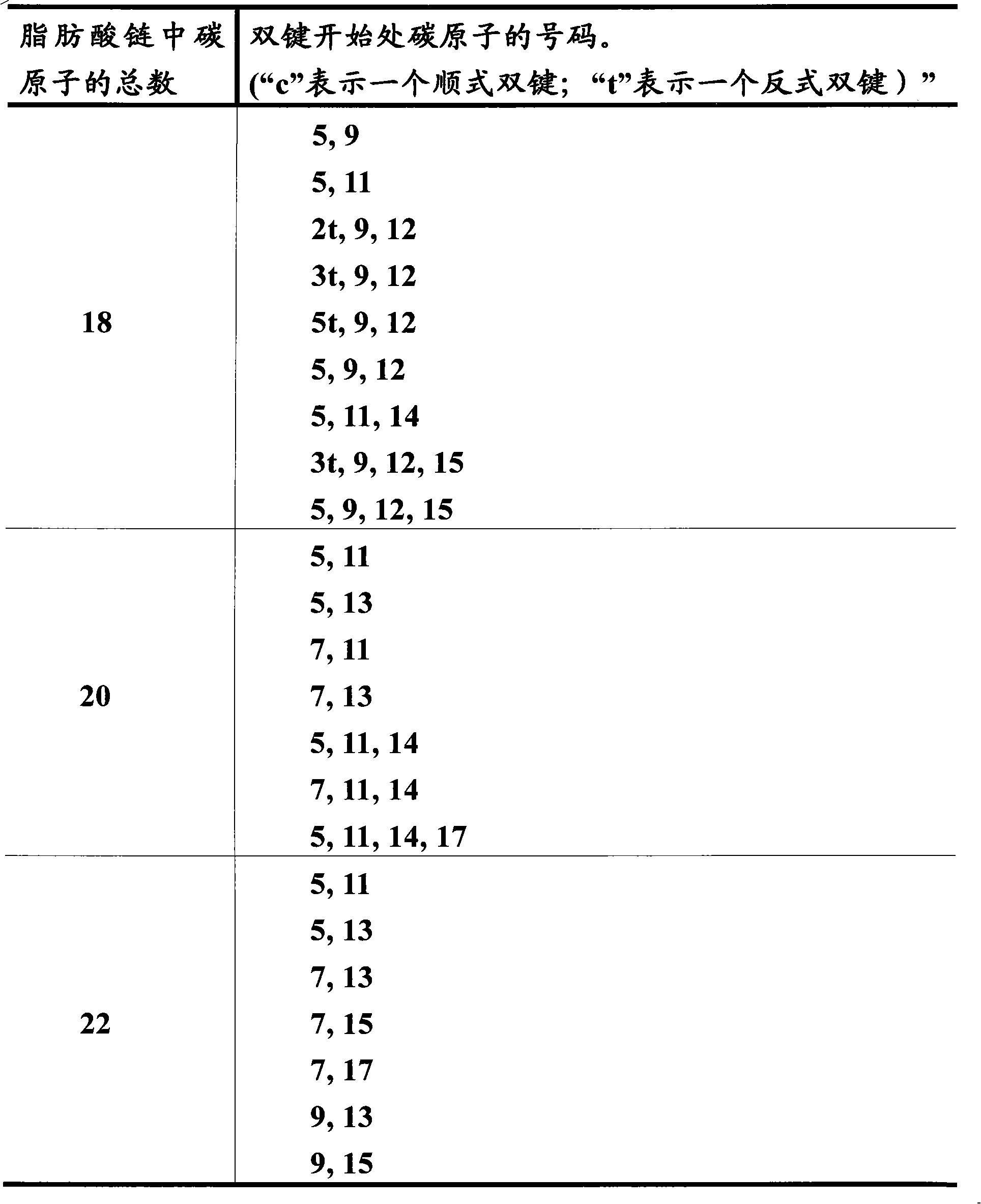

Method used

Image

Examples

example 1

[0156] Example 1: Microencapsulation using WPI / Agar-WPI / Gellan Gum

[0157] 4.0 grams of agar (TIC Pretested Agar; TIC Gums; Belcamp, MD) was added to 100.0 grams of boiling water to rehydrate and dissolve. The resulting solution was then transferred to a 2 L reactor with 600.0 g of deionized water maintained at 65°C. Next, 1.0 g of sodium ascorbate was added to the solution in the reactor, and the pH was determined to be about 6.6.

[0158] 35.0 g of WPI (Whey Protein Isolate) was mixed by stirring at room temperature (25°C) 895, NZMP (USA) Inc., Lemoyne, PA) was added to 90.0 g deionized water. The dissolved WPI was then cooled to 10°C. 70.0 g of fish oil (XODHA from Ocean Nutrition Canada, Ltd.; Dartmouth, NS) was added to the cold WPI solution and passed through a Polytron PT 6100 TM The resulting mixture was emulsified with a homogenizer (Kinematica AG, Lucerne, Switzerland) at 8000 rpm for 5 minutes while the temperature was maintained at 10°C. The resulting emulsi...

example 2

[0161] Example 2: Microencapsulation using whey protein and low methoxyl pectin

[0162] 29.3g whey protein isolate (WPI, Alacen 895, NZMP (USA) Inc.) was dissolved in 322g water in a 2L reactor by stirring. The resulting solution was kept at 30°C, while 7 g of sodium ascorbate was subsequently added. Next, 15 g of fish oil (XO30TG, Ocean Nutrition Canada, Ltd.) was added to the WPI solution. Then use Polytron PT 6100 TM The homogenizer emulsifies the solution at 10,000 rpm for 5 minutes. Next, 972 g of distilled water was added to the obtained emulsion in the reactor while maintaining the temperature at 30°C. 4.6 g of pre-tested pectin LM32 from TIC Gums TM (Belcamp, MD) was dissolved in 168.2 g of distilled water and then added to the diluted emulsion in the reactor. The pH of the suspension was adjusted to about 3.1 with 10% phosphoric acid (about 50 mL) to form agglomerates of primary microcapsules of about 10 μm. The mixture was then heated from 30°C to 85°C at an a...

example 3

[0163] Example 3: Microencapsulation using pectin and low methoxyl pectin

[0164] 570 g of deionized water were added to a reactor and heated to approximately 53°C. 8.0g low methoxyl pectin (LM-12CG TM , from C.P. Kelco; San Diego, CA) dissolved in 349 g of water at approximately 53°C. 40.0 g fish gelatin (240 Bloom from LAPI; Tuscany, Italy) was dissolved in 293 g water at 53°C. After the gelatin was completely dissolved, 6.1 g of sodium ascorbate was added to the gelatin solution. Then 72.0 g of DHA oil (XODHA, Ocean Nutrition Canada, Ltd.) was added to the gelatin solution, and a Polytron PT 6100 TM The homogenizer emulsifies the resulting mixture at 7500 rpm for 4 minutes. Then, the emulsion was added to the water in the reactor, and the pH of the solution was adjusted to 8.04. The pectin solution was then added to the reactor and coagulation started with the addition of citric acid (up to pH 4.52) and reached the desired particle size (approximately 30 μm). The slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com