A rare earth-containing halogen-free sn-ag-cu solder paste

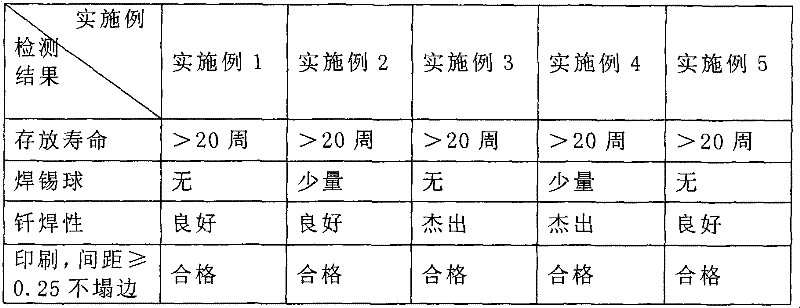

A solder paste and halogen technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of poor refinement of alloy solder powder, low elongation of alloy solder powder, poor mechanical properties of solder paste, etc. , to achieve the effect of less residue after welding, long storage life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

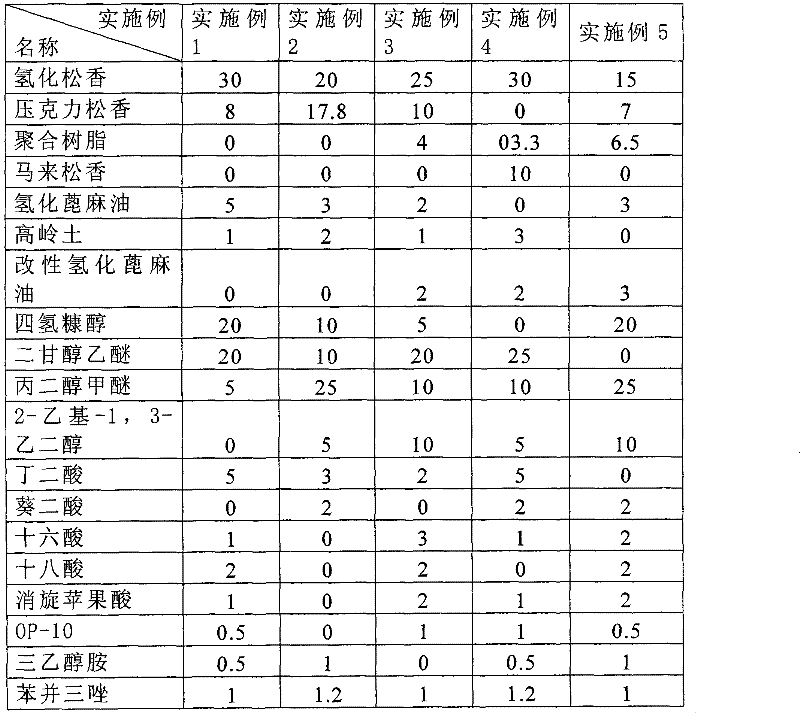

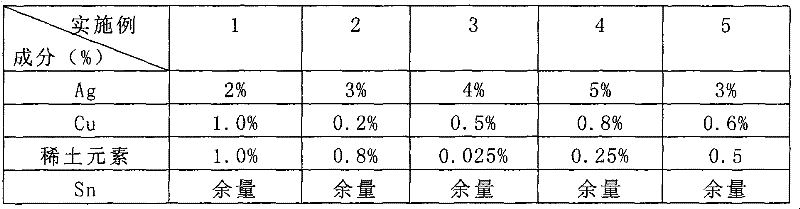

[0032] The preparation method of the rare earth-containing halogen-free Sn-Ag-Cu based solder paste described in Example 1 is as follows: take the solder paste components in parts by weight of Example 1 in Table 1, and mix rosin and its derivatives, organic acid The active agent, surfactant, solvent, and antioxidant materials are sequentially added into the container for heating, and the temperature is not higher than 100°C, stirred and dissolved, and then cooled to room temperature. Add thixotropic agent, disperse at high speed to 70°C, and then cool to room temperature to obtain solder paste.

[0033] Then 12.5% by weight of solder paste and 87.5% by weight of alloy solder powder were evenly stirred to obtain the rare earth-containing halogen-free Sn—Ag—Cu based solder paste described in Example 1.

Embodiment 2

[0034] The preparation method of the rare-earth-containing halogen-free Sn-Ag-Cu system solder paste described in Example 2 is: take the solder paste components by weight in Example 2 in Table 1, and all the other processes are the same as in Example 1, and no longer To repeat, get the solder paste.

[0035] Then 11.5% by weight of solder paste and 88.5% by weight of alloy solder powder were evenly stirred to obtain the rare earth-containing halogen-free Sn—Ag—Cu solder paste described in Example 2.

Embodiment 3

[0036] The preparation method of the rare-earth-containing halogen-free Sn-Ag-Cu based solder paste described in Example 3 is as follows: take the solder paste components in parts by weight of Example 3 in Table 1, and all the other processes are the same as in Example 1, and no longer To repeat, get the solder paste.

[0037] Then 10.5% by weight of solder paste and 89.5% by weight of alloy solder powder were stirred evenly to obtain the rare earth-containing halogen-free Sn—Ag—Cu solder paste described in Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com