Heat exchange medium and heat conduction pipe using same

A heat exchange medium and heat pipe technology, applied in the field of heat pipes, can solve the problems of increased carbon dioxide content, inconvenient installation, and more consumption, and achieve the effects of reducing water use, convenient installation, and reducing emissions

Inactive Publication Date: 2010-02-10

慧恒世纪科技(北京)有限公司

View PDF1 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Existing heat transfer tubes mostly use water to fill the inside of a single tube to achieve the purpose of heat transfer. Filling all the water into the heat transfer tube results in a large amount of water, and there will be a huge amount of water at the inlet and outlet of the heat transfer tube during the heat transfer process. The temperature drops. Therefore, in order to keep the heat pipe at a constant temperature normally, the temperature of the water must be kept basically constant. At this time, the boiler needs to provide more heat energy to continuously heat the heat exchange medium, thus consuming more energy, such as electric energy. Or fossil fuels, etc., which lead to an increase in the carbon dioxide content in the air; considering the convective heat environment, the existing heat pipe can only be installed according to a certain inclination angle, which is inconvenient to install

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0021] Mix 261 grams of anhydrous methanol; 601 grams of anhydrous ethanol; and 138 grams of anhydrous n-propanol.

Embodiment 2

[0023] Mix 300 grams of anhydrous methanol; 500 grams of anhydrous ethanol; and 200 grams of anhydrous propanol.

Embodiment 3

[0025] Mix 200 grams of anhydrous methanol; 700 grams of anhydrous ethanol; and 100 grams of anhydrous propanol.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

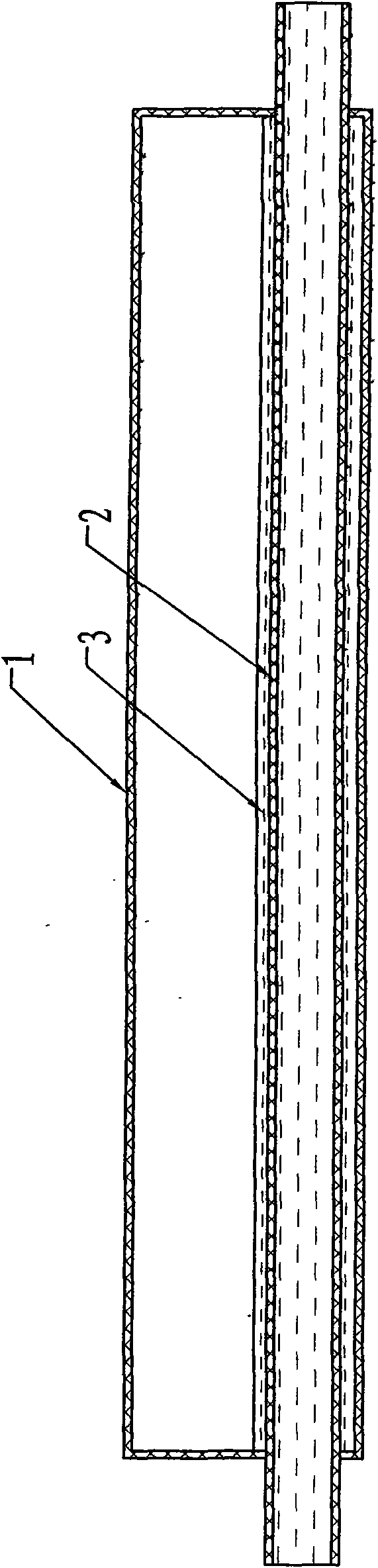

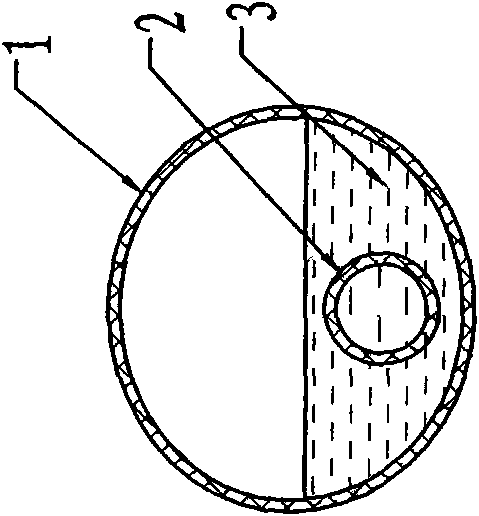

The invention relates to a heat exchange medium which is prepared from the following raw materials according to the weight ratio: 20-40 parts of absolute methyl alcohol, 50-70 parts of absolute ethanol and 10-20 parts of absolute n-propyl alcohol. The absolute methyl alcohol, the absolute ethanol and the absolute n-propyl alcohol are mixed as the heat exchange medium. A heat conduction pipe usingthe heat exchange medium comprises a heat dissipation outer pipe, a heat dissipation inner pipe and a heat exchange medium, wherein the heat dissipation inner pipe is arranged in the heat dissipationouter pipe, and the heat exchange medium is filled between the heat dissipation outer pipe and the heat dissipation inner pipe. Therefore, the heat conduction pipe having the advantages of energy saving, environmental protection and convenient installation is provided.

Description

technical field [0001] The invention relates to a heat exchange medium and a heat transfer pipe, in particular to a heat exchange medium with a low boiling point and a heat transfer pipe using two heat dissipation pipes and the heat exchange medium is filled between the heat dissipation pipes. Background technique [0002] Most of the existing heat pipes are filled with water inside a single pipe to achieve the purpose of heat conduction. All the water is filled into the heat pipe, resulting in a large amount of water, and during the heat conduction process, there will be huge amounts of water at the inlet and outlet of the heat pipe. The temperature drops. Therefore, in order to keep the heat pipe at a constant temperature, it is necessary to keep the temperature of the water basically constant. At this time, the boiler needs to provide more heat energy to continuously heat the heat exchange medium, thereby consuming more energy, such as electricity. Or fossil fuels, etc., ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09K5/04F28D15/02F28F21/08

Inventor 李先虎俞哲男

Owner 慧恒世纪科技(北京)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com