Rotary spray gun for use in molten iron desulfurization

The technology of molten iron desulfurization and rotary spray gun is applied in the direction of improving process efficiency, which can solve the problems of high efficiency of molten iron desulfurization process, large temperature drop of molten iron, low utilization rate of sulfur, etc. The effect of sulfur residue accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

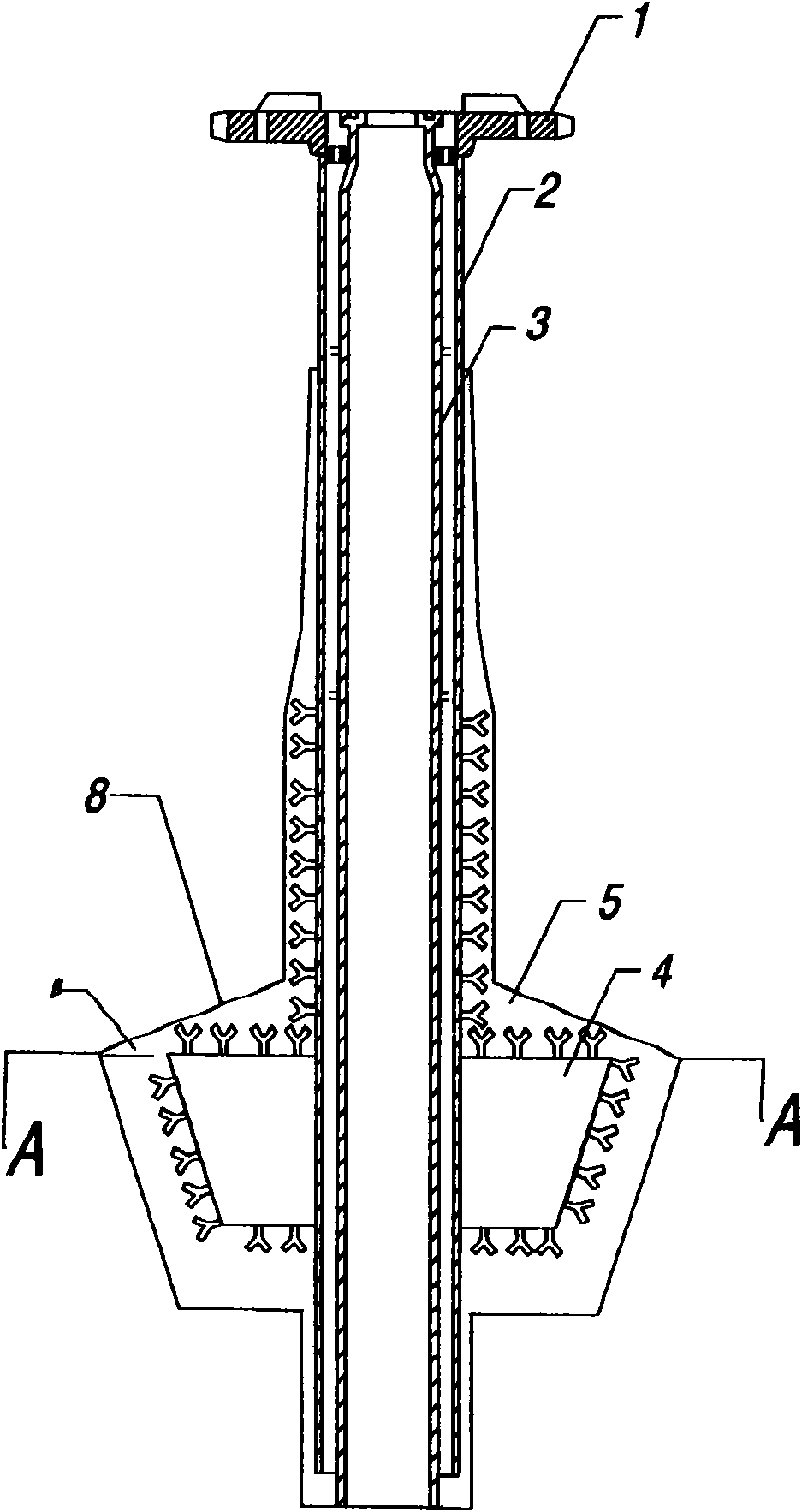

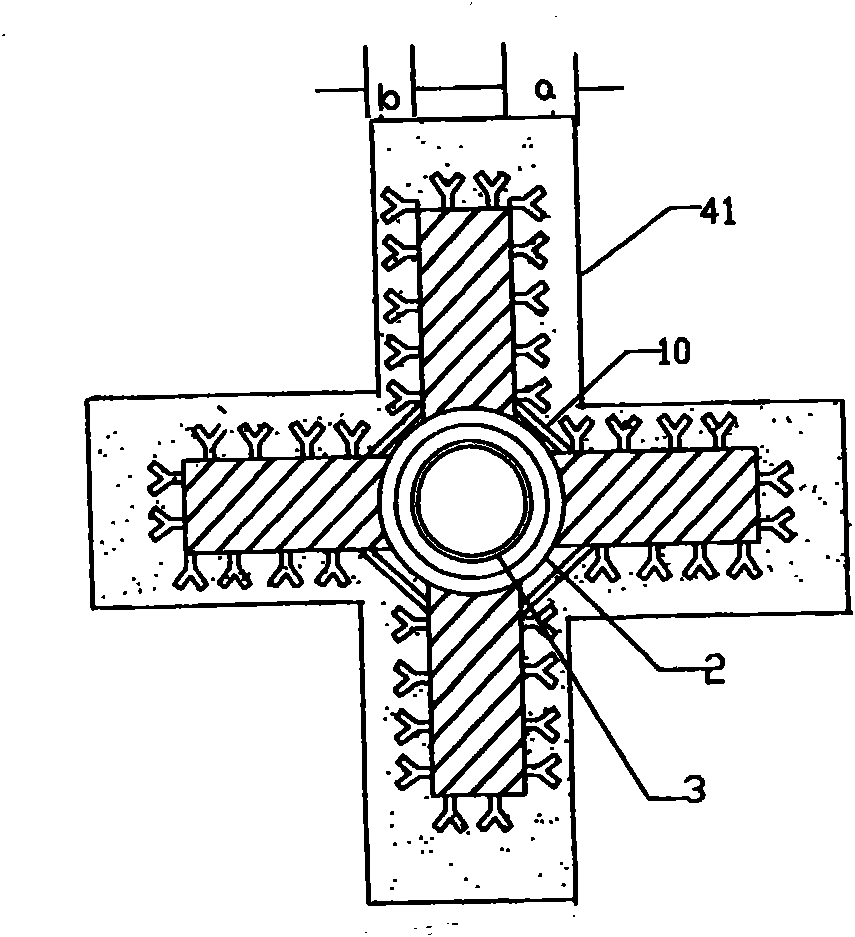

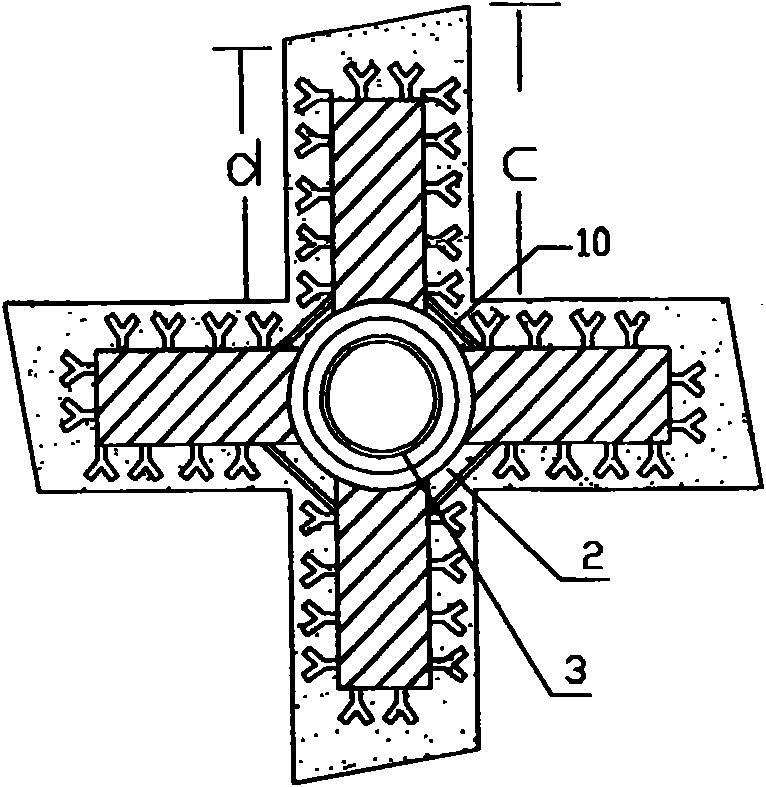

[0016] Such as figure 1 As shown, a rotary spray gun for desulfurization of molten iron comprises: a flange connector 1, an outer pipe 2 fixedly connected to the flange connector 1, a stirring blade 4 fixedly connected to the lower part of the stirring shaft 2, and a 2 and the refractory material layer 5 on the stirring blade 4; the stirring blade 4 is a right-angled trapezoid; the off-angle β=15° between the top refractory layer plane 8 of the stirring blade 4 and the horizontal plane. In the present invention, an inner pipe 3 can also be provided in the outer pipe 2 . Such as figure 2 , in order to prolong the service life, the cross section of the stirring blade 4 of the present invention is a "ten" structure; the thickness a of the front face 41 of the stirring blade 4 refractory material layer is greater than the back thickness b of the stirring blade 4 refractory material layer. In this way, the damage rate of the front surface 41 of the refractory material layer of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com