Vacuum heating furnace for smelting spongy titanium and spongy zirconium

A technology of vacuum heating furnace and sponge zirconium, which is applied in the field of sponge zirconium smelting vacuum heating furnace and sponge titanium, which can solve the problems of poor thermal insulation performance, high heating element power, large surface load, etc., and achieve good thermal insulation effect and power failure The effect of fast cooling and fast heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

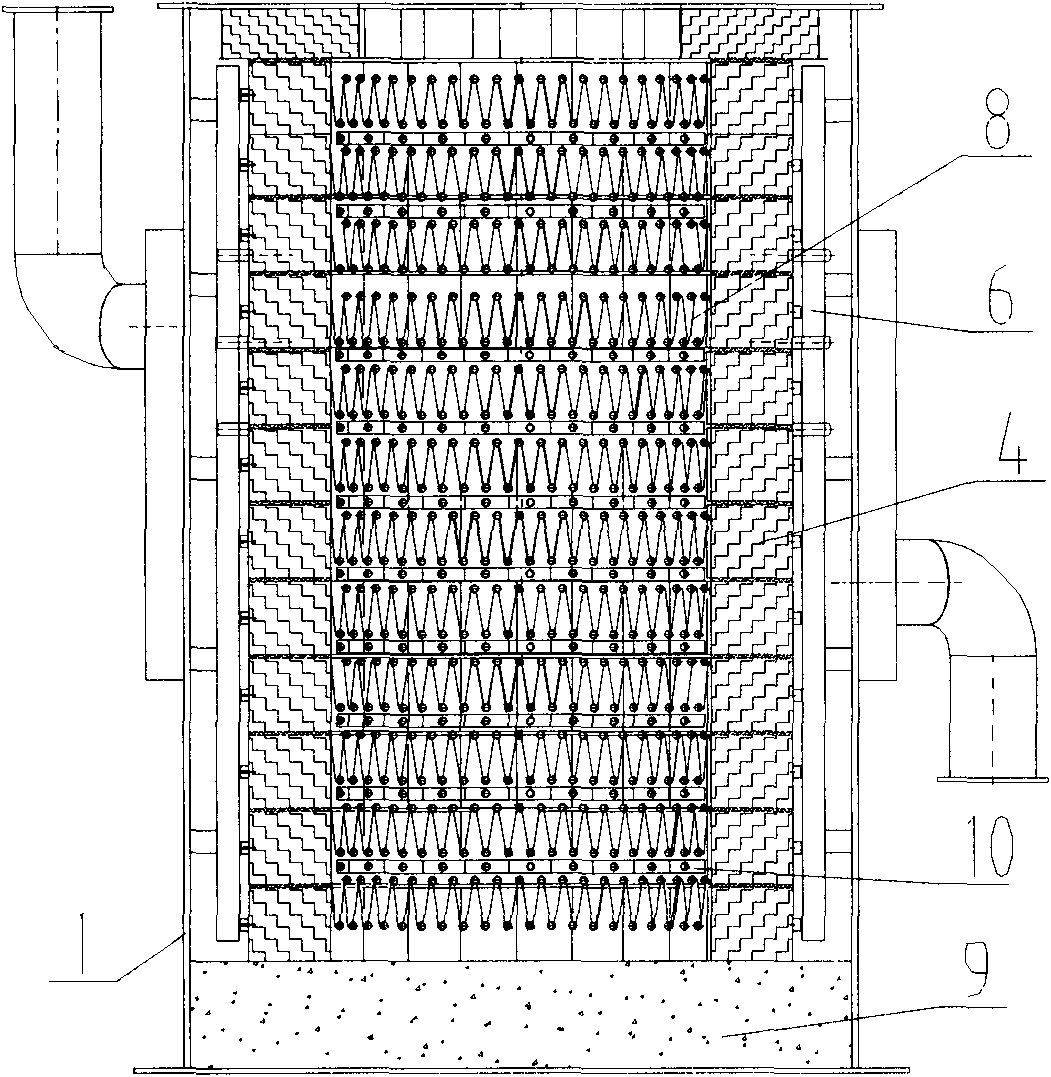

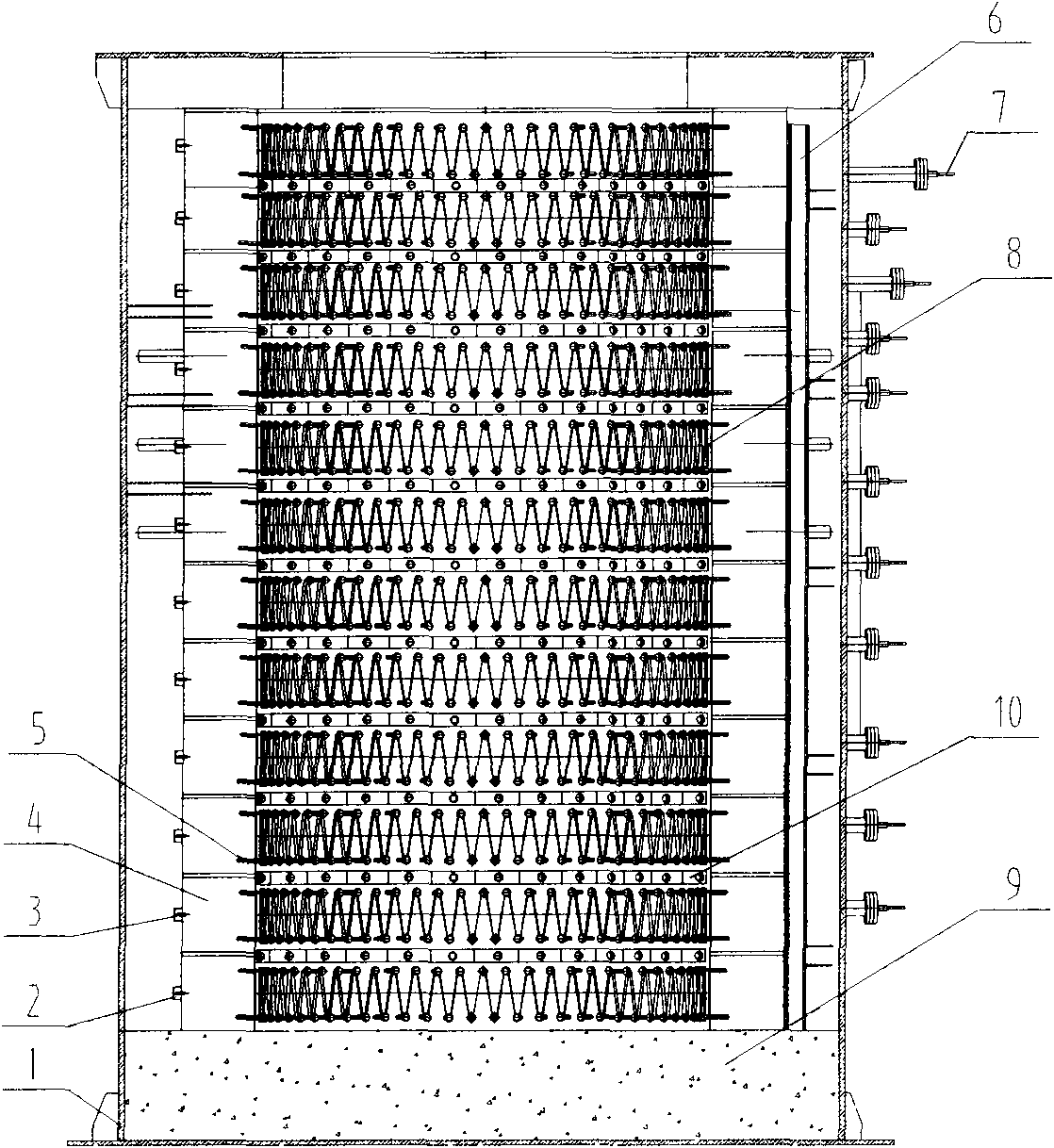

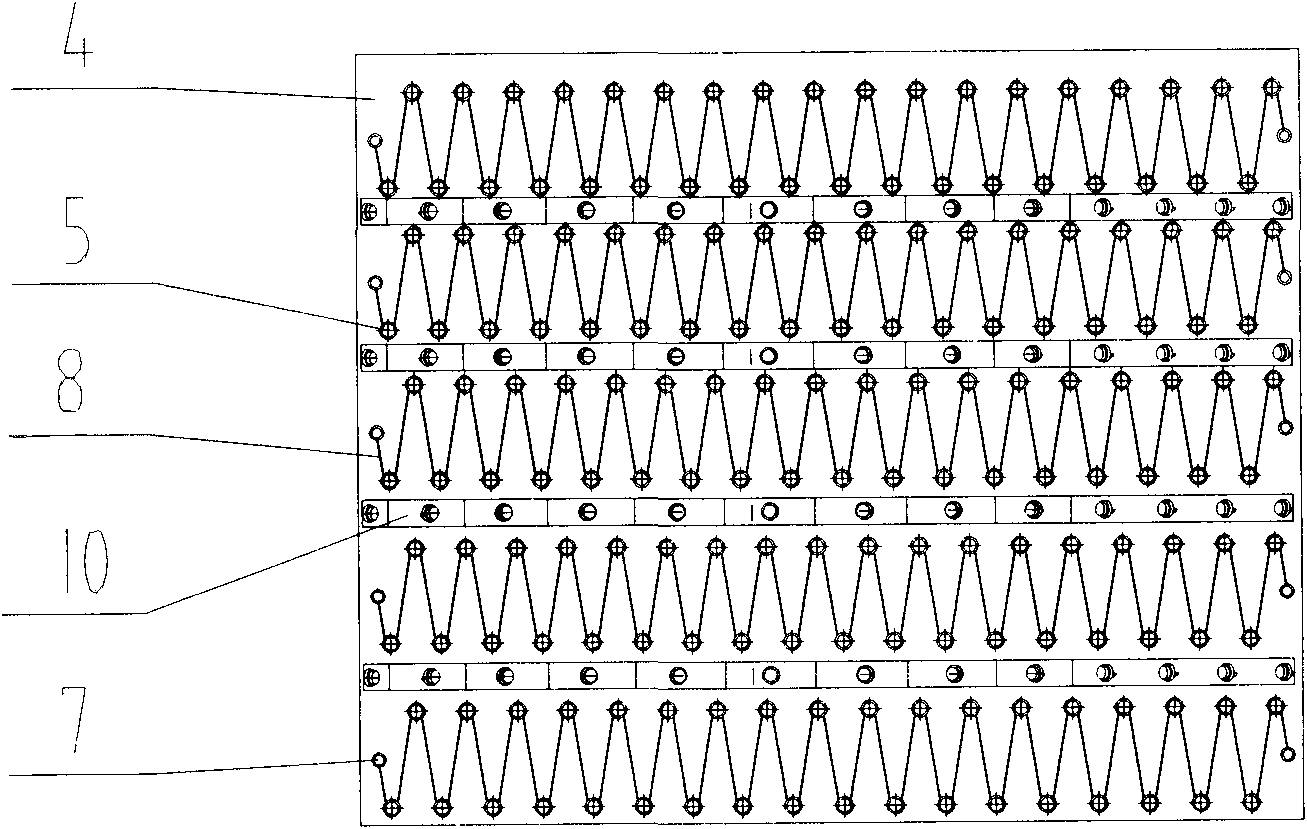

[0013] Depend on figure 1 It is known that it is a perspective view of the present embodiment. It is composed of a furnace shell 1, a furnace and an electric furnace control system. The inner lining of the furnace is a fiber module 4, and there are high-temperature resistance bands fixed by ceramic nails 5 anchors along the circumference of the fiber module 4. 8, ceramic nails 5 are arranged to fix the brim of the hat 10, after preventing the reactor iron sheet from coming off, it falls on the resistance band.

[0014] Depend on figure 2 Known, is the sectional view of the present invention. The high-temperature-resistant fiber module 4 is a white high-temperature-resistant fiber module. The module is extruded to make a hollow cylinder-shaped furnace lining. The furnace lining is fixed on the furnace frame welded by channel steel 6 and flat iron 3, and fixed by anchors. it is good. The conductive rod 7 is connected outside the furnace body, and the bottom of the furnace sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com