Epitaxial method for preparing AlGaAsSb/InGaAsSb multi-quantum wells by using AlSb buffer layer

A multi-quantum well and multi-quantum well layer technology is applied in the field of epitaxial growth of semiconductor laser materials and new semiconductor laser materials. It can solve the problems of high-quality material growth difficulty, antimonide material and device difficulty, etc., to improve quality and increase The effect of material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

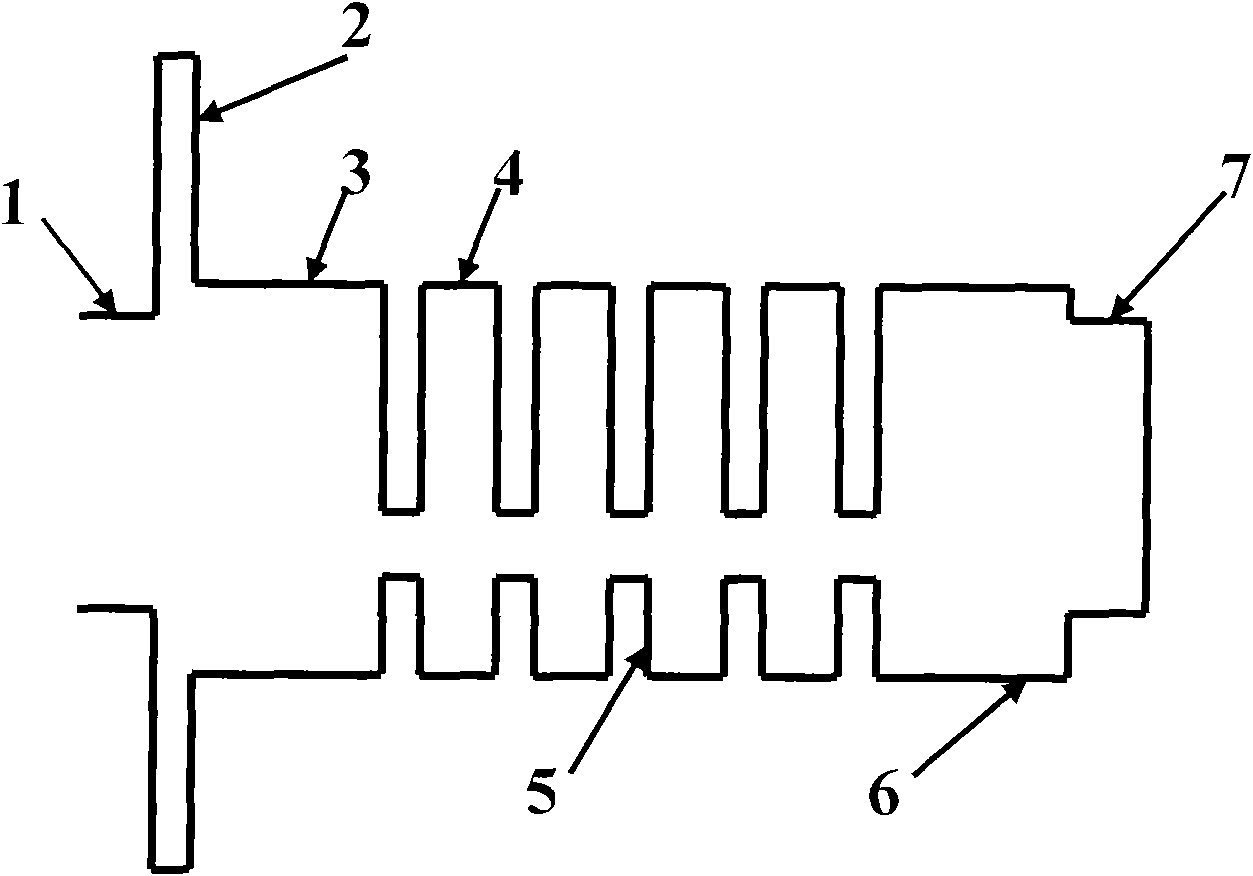

[0009] Such as figure 1 As shown, the structure of the AlGaAsSb / InGaAsSb multiple quantum well prepared by the AlSb buffer layer includes: n-type GaSb substrate (1); AlSb buffer layer (2); n-type Al 0.35 Ga 0.65 As 0.03 Sb 0.97 Lower confinement layer (3); 5 cycles of Al 0.35 Ga 0.65 As 0.03 Sb 0.97 / In 0.65 Ga 0.35 As 0.1 Sb 0.9 Multiple quantum well layer (4) / (5); p-type Al 0.35 Ga 0.65 As 0.03 Sb 0.97 Upper confinement layer (6); p-type GaSb ohmic layer (7).

[0010] In the following, the present invention will be explained with examples, and the equipment used is molecular beam epitaxy equipment (MBE).

[0011] On GaSb substrate (1), Te doping concentration is 1~2×10 17 cm -3 The GaSb crystal material grows sequentially;

[0012] AlSb buffer layer (2), the growth temperature is 500℃, and the thickness is 30nm;

[0013] Al 0.35 Ga 0.65 As 0.03 Sb 0.97 Lower confinement layer (3), growth temperature 520℃, Te doping, concentration 5×10 18 cm -3 , Grow 0.3μm;

[0014] 5 cycles of 15nm-A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com